Feeling lost in a sea of interview questions? Landed that dream interview for Comb Fixer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Comb Fixer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

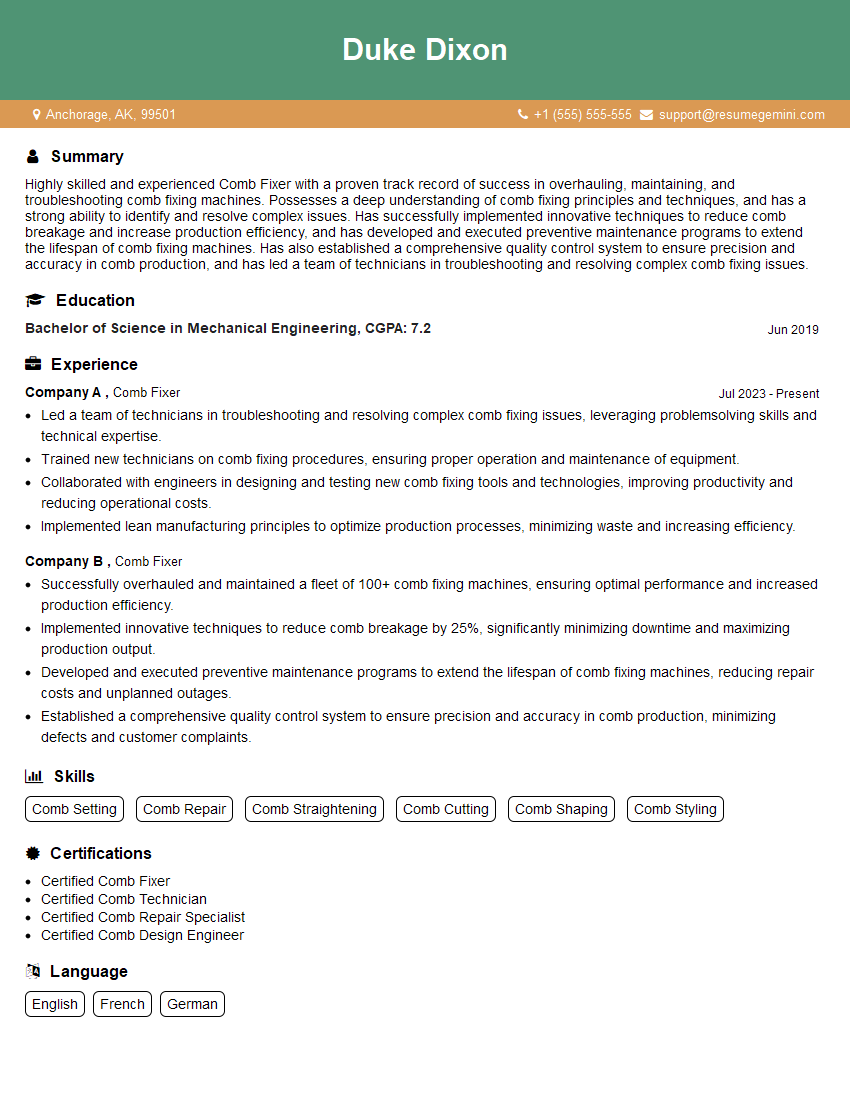

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Comb Fixer

1. What is the purpose of a comb fixer in the textile manufacturing industry?

Comb fixers are responsible for maintaining and repairing comb doffing machines used in the textile industry.

- Ensure the efficient operation of comb doffing machines

- Maintain and repair various components of the machine, including gears, bearings, and electrical systems

2. Describe the typical process of comb fixing in textile manufacturing.

Setting up the machine

- Calibrate and adjust the machine settings according to the specifications of the textile being processed

- Position and secure the comb doffer on the machine

Troubleshooting and repair

- Identify and diagnose any issues or malfunctions with the comb doffer

- Disassemble the machine, replace faulty components, and realign parts

Testing and verification

- Test the repaired comb doffer to ensure it meets performance standards

- Make any necessary adjustments or fine-tuning

3. What safety precautions should be observed when working with comb fixing machinery?

Comb fixing machinery can pose safety hazards if not operated properly.

- Wear appropriate safety gear, including gloves, eye protection, and earplugs

- Follow lockout/tagout procedures before performing any maintenance or repairs

- Keep the work area clean and free of debris

- Be aware of moving parts and potential pinch points

4. How do you stay up-to-date with the latest advancements in comb fixing technology?

The textile industry is constantly evolving, and it’s important for comb fixers to stay informed about the latest advancements.

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Participate in online forums and discussion groups

- Take advantage of training opportunities offered by equipment manufacturers

5. Describe a challenging comb fixing project you encountered and how you resolved it.

Comb fixers often troubleshoot and resolve complex issues with comb doffing machines.

- Provide a specific example of a challenging project you faced

- Describe the steps you took to diagnose and resolve the issue

- Highlight your problem-solving skills and technical expertise

6. What are some common issues that you encounter when fixing combs?

- Worn or damaged gears

- Misaligned or loose components

- Electrical faults

- Mechanical jams

- Improper calibration

7. What types of tools and equipment are essential for a comb fixer to have?

- Wrenches and screwdrivers

- Pliers and cutters

- Measuring and alignment tools

- Electrical testing equipment

- Specialized tools for comb doffing machines

8. How do you ensure the quality of your work as a comb fixer?

- Adhere to established quality standards and procedures

- Thoroughly test and inspect repaired comb doffers before returning them to production

- Document all maintenance and repairs performed

- Seek feedback from operators and supervisors to identify areas for improvement

9. What is your approach to working as part of a team?

- Communicate effectively with team members

- Collaborate on problem-solving and decision-making

- Share knowledge and expertise with colleagues

- Support other team members and contribute to a positive work environment

10. Why are you interested in this comb fixer position with our company?

Research the company and industry to demonstrate your interest and knowledge.

- Highlight your passion for the textile industry and your desire to contribute to the company’s success

- Explain how your skills and experience align with the requirements of the position

- Express your enthusiasm for working in a dynamic and challenging environment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Comb Fixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Comb Fixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Comb Fixers play a vital role in ensuring the smooth operation of textile manufacturing facilities. Their responsibilities encompass a wide range of tasks related to the maintenance and repair of combing machines, which are crucial for producing high-quality yarn.

1. Machine Maintenance and Troubleshooting

- Conduct routine maintenance and inspections of combing machines to identify potential issues.

- Troubleshoot and resolve machine malfunctions, ensuring optimal performance.

- Replace and adjust machine components, such as needles, brushes, and feed rollers.

2. Yarn Quality Control

- Monitor yarn quality and identify defects, such as neps, slubs, and unevenness.

- Adjust machine settings to optimize yarn quality and minimize defects.

- Collaborate with other team members to ensure consistent yarn production.

3. Production Monitoring and Optimization

- Monitor machine performance and identify bottlenecks or production inefficiencies.

- Coordinate with production supervisors to optimize machine utilization and increase productivity.

- Suggest and implement process improvements to enhance efficiency and quality.

4. Safety and Compliance

- Follow established safety protocols and adhere to occupational health and safety regulations.

- Ensure that machines are operated safely and in compliance with safety standards.

- Maintain a clean and organized work environment.

Interview Tips

Preparing thoroughly for an interview is crucial for maximizing your chances of success. Here are some tips and hacks to help you ace the interview for a Comb Fixer position:

1. Research the Company and Industry

- Learn about the textile manufacturing industry, including current trends and challenges.

- Research the company’s history, products, and values.

- Understanding the company’s goals and objectives will enable you to align your skills and experience with their needs.

2. Highlight Relevant Experience

- Emphasize your experience in combing machine maintenance, troubleshooting, and yarn quality control.

- Quantify your accomplishments whenever possible to demonstrate your impact.

- For example, you could mention the percentage increase in machine uptime or the reduction in yarn defects achieved through your efforts.

3. Prepare for Technical Questions

- Be prepared to answer technical questions about combing machines and yarn production processes.

- Review the basic principles of combing, including the different types of combs and their functions.

- Demonstrate your troubleshooting skills by providing examples of how you have resolved machine malfunctions in the past.

4. Practice Your Communication Skills

- Comb Fixers often work with other team members, such as production supervisors and technicians.

- Practice communicating complex technical information clearly and effectively.

- Be able to articulate your ideas and suggestions in a persuasive manner.

5. Emphasize Safety and Compliance

- Textile manufacturing involves potential safety hazards, so emphasize your commitment to following safety protocols.

- Highlight your knowledge of occupational health and safety regulations and your experience in maintaining a safe work environment.

- This will demonstrate your responsibility and attention to detail.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Comb Fixer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.