Are you gearing up for an interview for a Comber position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Comber and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

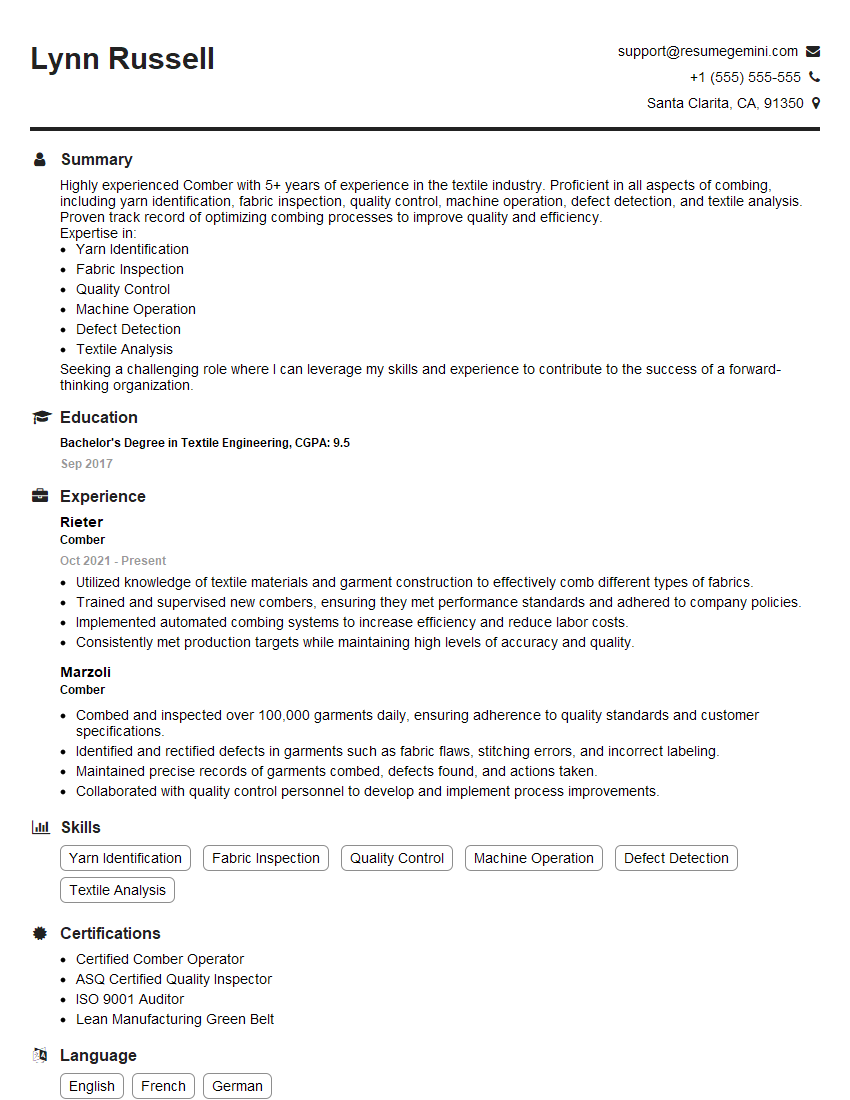

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Comber

1. What are the primary tasks and responsibilities of a Comber?

The primary tasks and responsibilities of a Comber include:

- Operating combing machines to prepare fibers for textile production

- Adjusting and maintaining combing machines to ensure optimal performance

- Inspecting fibers to identify and remove any defects or impurities

- Ensuring that the combing process meets quality standards

- Maintaining a clean and safe work area

2. What are the different types of combing machines used in the industry?

Automatic combing machines

- These machines are fully automated and require minimal operator intervention.

- They are highly efficient and can produce large quantities of combed fibers.

Semi-automatic combing machines

- These machines require some operator intervention, such as loading and unloading fibers.

- They are less efficient than automatic machines but are more affordable.

Manual combing machines

- These machines are operated entirely by hand.

- They are the least efficient but are also the most affordable.

3. What are the key factors to consider when selecting the right combing machine for a specific application?

The key factors to consider when selecting a combing machine include:

- The type of fibers to be combed

- The desired quality of the combed fibers

- The production capacity required

- The budget available

- The level of automation desired

4. What are the typical operating parameters of a combing machine?

The typical operating parameters of a combing machine include:

- Speed: The speed of the combing rollers determines the rate at which fibers are processed.

- Temperature: The temperature of the combing rollers affects the quality of the combed fibers.

- Pressure: The pressure applied to the combing rollers determines the amount of combing action.

- Roller spacing: The spacing between the combing rollers determines the fineness of the combed fibers.

5. How do you troubleshoot a combing machine when it is not operating properly?

When a combing machine is not operating properly, the first step is to identify the problem.

- Inspect the machine for any obvious damage or wear.

- Check the operating parameters to ensure that they are within the correct range.

- Clean the machine to remove any debris or lint that may be causing problems.

- Lubricate the machine to ensure that all moving parts are operating smoothly.

- If the problem persists, contact the manufacturer for assistance.

6. What are the safety precautions that should be taken when operating a combing machine?

The following safety precautions should be taken when operating a combing machine:

- Wear appropriate safety gear, such as gloves, safety glasses, and a dust mask.

- Keep hands and loose clothing away from moving parts.

- Do not operate the machine if it is damaged or not functioning properly.

- Follow all manufacturer’s instructions for safe operation.

7. What are the different types of fibers that can be combed?

A variety of fibers can be combed, including:

- Natural fibers, such as cotton, wool, and silk

- Synthetic fibers, such as polyester, nylon, and acrylic

- Blended fibers, which are a combination of natural and synthetic fibers

8. What are the benefits of combing fibers?

Combing fibers provides a number of benefits, including:

- Improved fiber quality: Combing removes impurities and defects from fibers, resulting in higher quality fibers.

- Increased fiber strength: Combing aligns the fibers in a parallel direction, which increases their strength.

- Reduced fiber breakage: Combing removes weak and damaged fibers, which reduces fiber breakage during processing.

- Improved fabric appearance: Combed fibers produce fabrics with a smoother and more uniform appearance.

9. What are the different applications of combed fibers?

Combed fibers are used in a variety of applications, including:

- Textiles: Combed fibers are used to produce high-quality fabrics for clothing, bedding, and other textile products.

- Yarn: Combed fibers are used to produce strong and durable yarn for knitting and weaving.

- Non-woven fabrics: Combed fibers are used to produce non-woven fabrics for a variety of applications, such as filters, medical products, and wipes.

10. What is the future of combing technology?

The future of combing technology is promising. New developments in combing technology are focused on increasing efficiency, improving fiber quality, and reducing costs.

- Increased efficiency: New combing machines are being developed that are more efficient and can process more fibers in less time.

- Improved fiber quality: New combing techniques are being developed that can produce higher quality fibers with fewer defects.

- Reduced costs: New combing technologies are being developed that can reduce the cost of combing fibers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Comber.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Comber‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Comber

A comber is responsible for operating combing machines to remove impurities and align fibers in preparation for spinning into yarn. Key job responsibilities include:1. Machine Operation and Maintenance

- Loading and feeding raw cotton or other fibers into the combing machine.

- Operating and adjusting combing machines to ensure proper fiber alignment and removal of impurities.

- Performing routine maintenance and troubleshooting of combing machines.

- Monitoring machine performance and making necessary adjustments to optimize efficiency.

2. Fiber Quality Inspection

- Inspecting combed fibers to ensure they meet quality standards.

- Identifying and removing any remaining impurities or imperfections in the fibers.

- Providing feedback to supervisors or quality control personnel on fiber quality.

3. Production Monitoring

- Maintaining records of production output and machine efficiency.

- Monitoring and optimizing machine settings to increase productivity.

- Collaborating with supervisors and other team members to improve production processes.

4. Safety and Compliance

- Adhering to all safety regulations and protocols.

- Maintaining a clean and organized work area.

- Wearing appropriate personal protective equipment.

Interview Tips for Comber Candidates

To ace the interview for a comber position, candidates should:1. Research the Company and Industry

- Learn about the company’s history, products, and commitment to quality.

- Understand the role of combing in the textile manufacturing process.

- Familiarize yourself with industry trends and best practices.

2. Highlight Relevant Skills and Experience

- Emphasize your experience in operating and maintaining combing machines.

- Showcase your ability to ensure fiber quality and meet production targets.

- Describe your commitment to safety and following industry regulations.

3. Practice Common Interview Questions

- Prepare answers to questions about your experience, skills, and motivations.

- Consider questions related to combing machine operation, fiber quality assessment, and production optimization.

- Practice STAR method (Situation, Task, Action, Result) to provide detailed and specific examples.

4. Prepare Questions for the Interviewer

- Ask questions to demonstrate your interest in the company and role.

- Inquire about the company’s production processes, quality standards, and training opportunities.

- Show your enthusiasm for the industry and your desire to contribute to the team.

5. Dress Professionally and Arrive on Time

- Make a good first impression by dressing appropriately for the interview.

- Punctuality demonstrates your respect for the interviewer’s time.

- Maintain a positive and professional demeanor throughout the interview.

Next Step:

Now that you’re armed with the knowledge of Comber interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Comber positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini