Feeling lost in a sea of interview questions? Landed that dream interview for Comber Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Comber Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

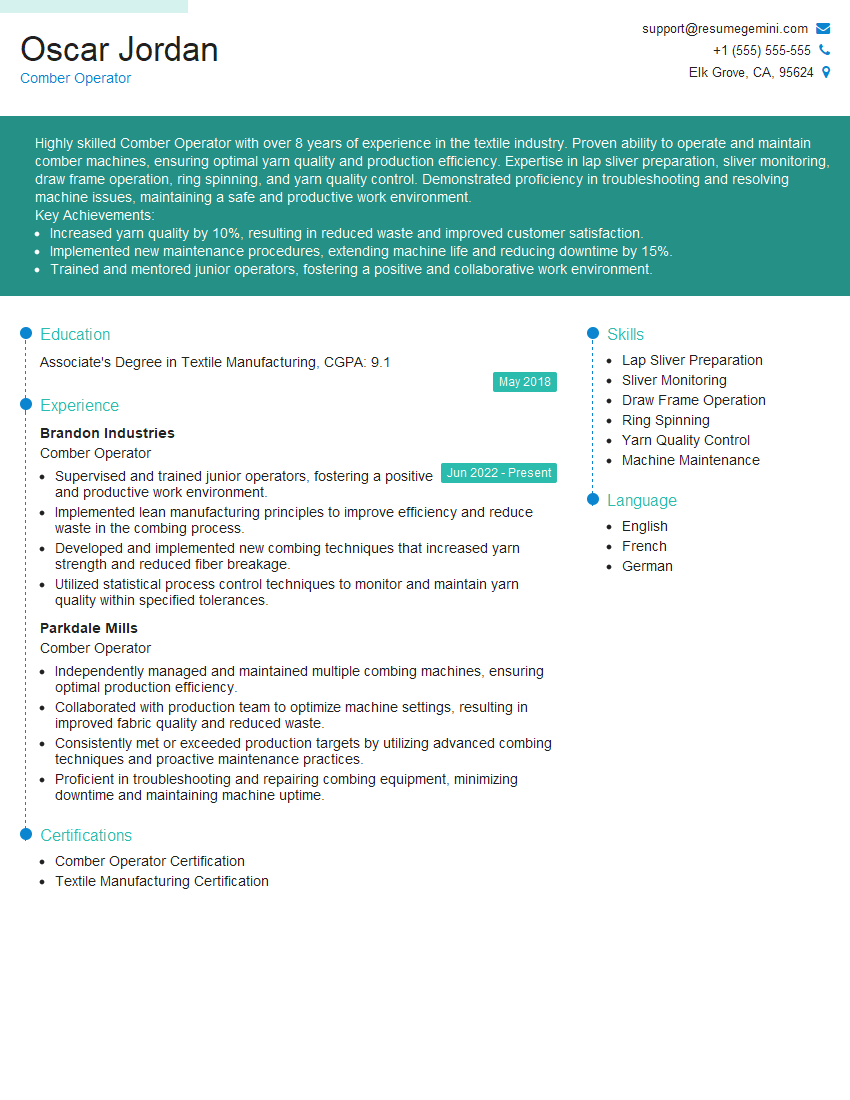

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Comber Operator

1. Explain the process of sliver preparation in comber machine?

- The process of sliver preparation in a comber machine involves a series of steps:

- The raw cotton fibers are first fed into the machine, where they are loosened and separated by a series of rollers.

- The fibers are then drawn through a series of combs, which remove impurities and short fibers.

- The combed fibers are then gathered into a continuous sliver, which is then wound onto a bobbin.

- The sliver is then ready to be used in the next stage of textile production.

2. What are the different types of comber machines?

Flat comber and Circular comber

- Flat comber: In a flat comber, the combing elements are arranged in a flat plane.

- Circular comber: In a circular comber, the combing elements are arranged in a circular pattern.

3. What are the major components of comber machine?

- The major components of comber machine are:

- Feed rollers

- Nipper

- Detaching rollers

- Combing head and detaching knives

- Top comb and bottom comb

- Clearer rollers

- Sliver forming funnel and bobbin

4. What is lap formation in comber machine?

- Lap formation is the process of combining multiple slivers into a single, cohesive sheet of material.

- In a comber machine, lap formation is typically achieved by passing the slivers through a series of rollers that press them together.

- The resulting lap is then wound onto a bobbin for storage or further processing.

5. What are the factors that affect the quality of combed sliver?

- The quality of combed sliver is affected by a number of factors, including:

- The quality of the raw cotton fibers

- The settings of the comber machine

- The skill of the machine operator

- The maintenance of the machine

6. What are the common problems in comber machine?

- Some of the common problems in comber machine are:

- Uneven sliver

- Neps and seed coat

- Thin place and Thick place

- Roller lapping

- Breakage of sliver

7. How to maintain comber machine?

- Regular maintenance is essential to keep a comber machine running smoothly and efficiently.

- Some of the maintenance tasks that should be performed on a regular basis include:

- Cleaning the machine

- Oiling and greasing the moving parts

- Checking the tension of the belts and chains

- Inspecting the combing elements for wear and tear

8. How to set a comber machine?

- Setting a comber machine involves adjusting a number of parameters, including:

- The speed of the machine

- The tension of the slivers

- The position of the combing elements

- The settings of the detaching knives

9. What is the role of comber operator?

- The role of a comber operator is to operate and maintain a comber machine.

- This involves a variety of tasks, including:

- Loading the machine with raw cotton

- Setting the machine parameters

- Monitoring the machine during operation

- Troubleshooting any problems that may occur

- Maintaining the machine on a regular basis

10. What are the safety precautions to be taken while working on comber machine?

- There are a number of safety precautions that should be taken while working on a comber machine, including:

- Wearing appropriate safety clothing

- Keeping the work area clean and free of debris

- Being aware of the moving parts of the machine

- Following the manufacturer’s instructions for operating and maintaining the machine

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Comber Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Comber Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Comber Operators play a crucial role in the textile industry, responsible for operating and maintaining combing machines. Their primary responsibilities include:

1. Machine Operation and Maintenance

A Comber Operator is accountable for the smooth operation and upkeep of combing machines. This involves:

- Setting up, calibrating, and adjusting machines to ensure optimal performance

- Monitoring machines during operation and making necessary adjustments to maintain efficiency

- Conducting routine maintenance, including cleaning, lubrication, and minor repairs

2. Raw Material Handling

Comber Operators are responsible for handling and preparing raw materials for combing. This may involve:

- Inspecting raw fiber for defects and removing impurities

- Feeding fiber into the combing machine and monitoring the process

- Ensuring that the correct fiber blend and weight are used according to production specifications

3. Quality Control

Maintaining high-quality standards is a key aspect of the role. Comber Operators must:

- Conduct regular quality checks on combed fiber to meet established specifications

- Identify and resolve any issues that affect fiber quality

- Communicate findings and recommendations to supervisors or quality control personnel

4. Production Monitoring

Comber Operators monitor production processes to ensure efficiency and productivity. Responsibilities include:

- Tracking production output and downtime

- Identifying bottlenecks and proposing solutions for improvement

- Maintaining production records and reporting any deviations from the plan

Interview Tips

To prepare for a Comber Operator interview, consider the following tips:

1. Research the Role and Company

Familiarize yourself with the specific responsibilities of a Comber Operator and the company you’re applying to. This shows the interviewer that you’re genuinely interested in the position and have taken the time to learn about the organization.

2. Highlight Relevant Skills and Experience

In your resume and interview, emphasize your skills in operating and maintaining combing machines. Quantify your experience whenever possible, using specific examples to demonstrate your abilities.

3. Practice Answering Common Interview Questions

Anticipate common interview questions related to your technical skills, problem-solving abilities, and attention to detail. Prepare concise and well-structured answers that highlight your strengths.

4. Emphasize Quality Standards

Comber Operators are responsible for maintaining high-quality standards. Highlight your commitment to quality control and your ability to identify and resolve issues that may affect fiber quality.

5. Showcase Teamwork and Communication Skills

Comber Operators often work in teams and interact with various departments. Demonstrate your ability to collaborate effectively, communicate clearly, and resolve conflicts professionally.

6. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare a few questions related to the company’s production processes, quality standards, or opportunities for advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Comber Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!