Are you gearing up for an interview for a Combination Machine Tool Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Combination Machine Tool Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

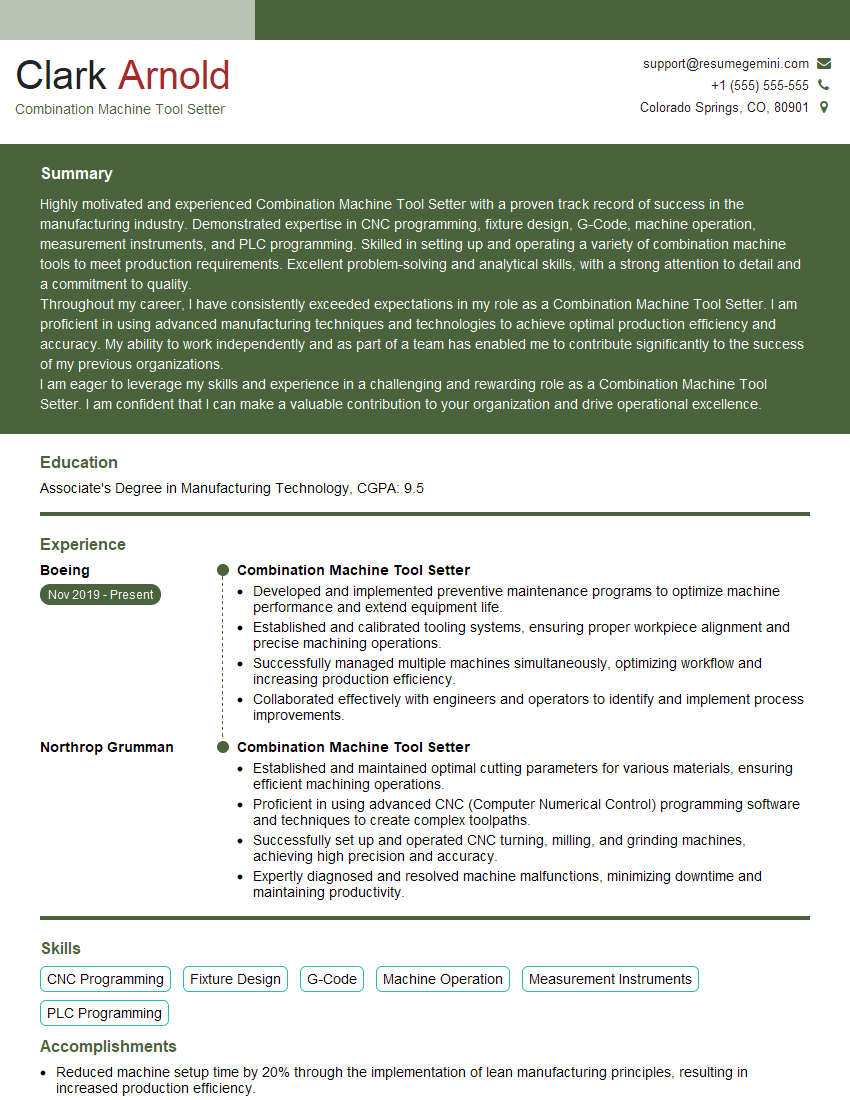

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Combination Machine Tool Setter

1. What is the purpose of using a slip gauge in machine tool setup?

- To measure precise distances and set cutting tools to exact dimensions.

- Slip gauges are made from hardened steel and come in a range of thicknesses, allowing for accurate measurement and adjustment.

2. Explain the process of setting up and aligning a boring bar on a horizontal boring mill.

- First, the boring bar is mounted on the machine and adjusted to the appropriate height and center line.

- Then, the boring head is attached to the bar and aligned using a dial indicator to ensure accuracy.

- Finally, the workpiece is secured and the boring operation can begin.

3. How do you troubleshoot a program running on a CNC machine tool?

- Check for any error messages displayed on the machine’s control panel or in diagnostic logs.

- Examine the program code for any syntax or logic errors.

- Use a debugger to step through the program and identify where the issue occurs.

4. Describe the different types of cutting tools used in a machine tool setup for milling operations.

- End mills: Used for cutting flat surfaces, slots, and pockets.

- Face mills: Used for milling flat surfaces on large workpieces.

- Ball end mills: Used for contour milling and creating curved surfaces.

5. What are the factors to consider when selecting cutting speeds and feeds for a particular machining operation?

- Material of the workpiece: Different materials have different machinability characteristics.

- Type of cutting tool: Each tool has its own recommended speed and feed ranges.

- Machine capabilities: Consider the spindle speed and torque of the machine.

6. How do you maintain and calibrate measuring equipment used in a machine tool workshop?

- Regular cleaning: Remove dirt, dust, and debris that can affect accuracy.

- Calibration: Use certified standards and follow manufacturer’s instructions for periodic calibration.

- Handling and storage: Handle and store equipment properly to prevent damage or degradation.

7. Describe the importance of using personal protective equipment (PPE) when working in a machine tool environment.

PPE is essential to protect against hazards such as:

- Eye injuries: Wear safety glasses or goggles to protect from flying chips and particles.

- Hearing damage: Use earplugs or earmuffs to reduce noise levels.

- Hand injuries: Wear gloves to protect from sharp edges and hot surfaces.

8. What are the common causes of machine tool vibration and how can they be reduced?

- Unbalanced rotating parts: Ensure proper balancing of components like chuck and spindle.

- Loose or worn components: Check and tighten all bolts, nuts, and bearings.

- Resonance: Avoid operating the machine at frequencies that coincide with the natural frequencies of its components.

9. How do you interpret technical drawings and specifications related to machine tool setups?

- Understand symbols and conventions: Learn the industry-standard symbols and abbreviations used in drawings.

- Identify critical dimensions: Pay attention to tolerances and surface finishes specified.

- Visualize the setup: Create a mental or physical model of the setup to ensure proper execution.

10. Explain the concept of tool life and how it affects machining operations.

- Tool life: The period during which a cutting tool can perform its function effectively.

- Factors affecting tool life: Cutting speed, feed rate, workpiece material, cutting fluid, etc.

- Importance: Tool life optimization reduces downtime, improves productivity, and lowers overall machining costs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Combination Machine Tool Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Combination Machine Tool Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Combination Machine Tool Setters are highly skilled professionals responsible for the efficient operation and maintenance of combination machine tools in manufacturing and production environments. Their primary duty is to ensure the accuracy and precision of these machines, which perform a range of complex machining operations.

1. Machine Setup and Calibration

Set up and calibrate combination machine tools according to specifications, ensuring accurate and efficient operation.

- Install and align cutting tools, fixtures, and workpieces.

- Establish and maintain optimal operating parameters, including speeds, feeds, and depths of cut.

2. Machine Operation and Monitoring

Operate combination machine tools to perform various machining processes, including turning, milling, boring, and grinding.

- Monitor machine performance and identify potential issues.

- Make necessary adjustments to maintain production efficiency and product quality.

3. Tool and Fixture Maintenance

Inspect, maintain, and repair tools and fixtures used in combination machine tools.

- Sharpen and replace cutting tools to ensure optimal performance.

- Clean and calibrate fixtures to maintain accuracy and precision.

4. Quality Control and Inspection

Conduct quality control inspections to ensure that machined parts meet specifications and standards.

- Utilize measuring tools and equipment to verify dimensions, tolerances, and surface finishes.

- Identify and correct deviations from specifications to maintain product quality.

Interview Tips

To ace an interview for a Combination Machine Tool Setter position, candidates should:

1. Research the Company and Role

Familiarize yourself with the company’s industry, products, and values. Understand the specific responsibilities and skills required for the position.

- Visit the company website, read industry publications, and connect with the hiring manager on LinkedIn.

- Prepare questions about the company’s operations and the role’s contribution to the team.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in machine setup, calibration, and operation. Quantify your experience and provide specific examples of your accomplishments.

- Showcase your knowledge of different combination machine tools, including their capabilities and limitations.

- Describe projects where you successfully diagnosed and resolved complex machine issues.

3. Demonstrate Attention to Detail and Quality

Convey your commitment to accuracy and precision. Describe your quality control processes and how you ensure that machined parts meet specifications.

- Provide examples of how you have identified and corrected errors in machine setup or operation.

- Discuss your experience in using measuring tools and equipment to verify dimensions and surface finishes.

4. Emphasize Your Problem-Solving Abilities

Highlight your ability to identify and resolve issues quickly and effectively. Explain your approach to troubleshooting and problem-solving.

- Describe a situation where you diagnosed and fixed a complex machine malfunction.

- Explain how you analyze data and identify patterns to resolve production issues.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Combination Machine Tool Setter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.