Are you gearing up for an interview for a Combination Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Combination Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

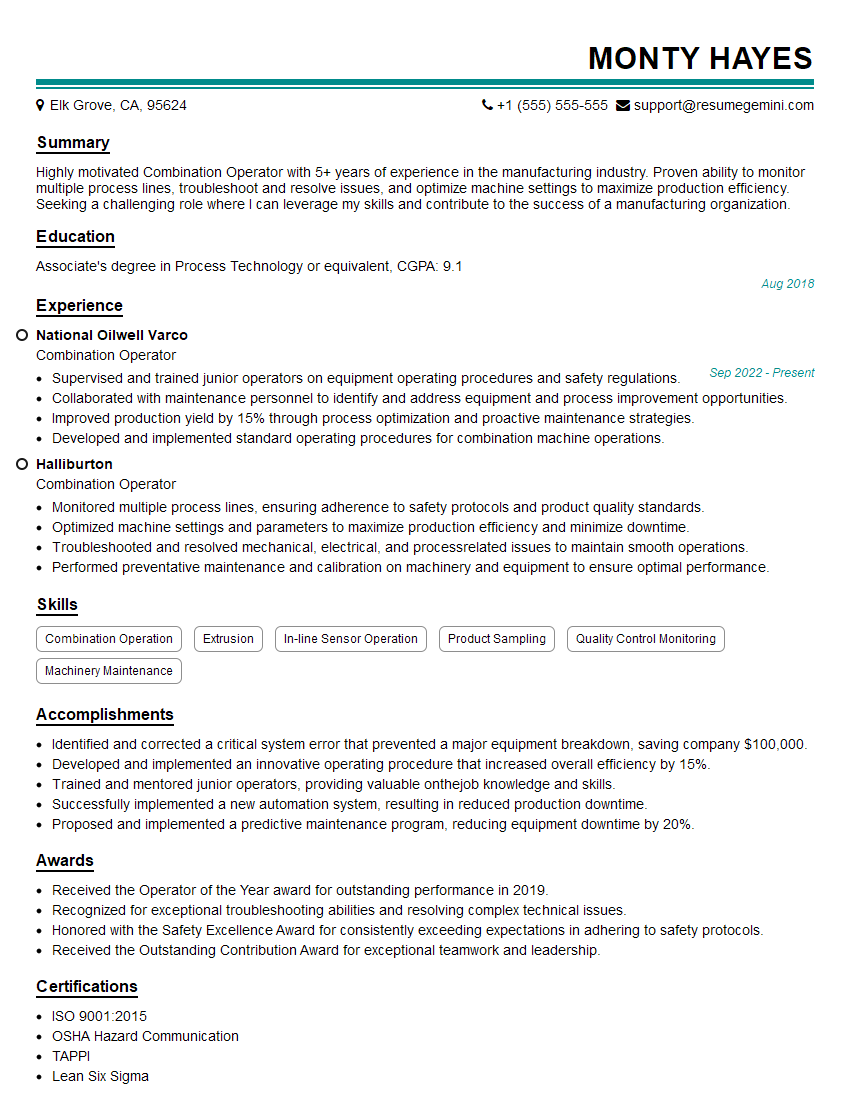

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Combination Operator

1. What are the primary responsibilities of a Combination Operator?

As a Combination Operator, my key responsibilities revolve around operating and maintaining production machinery used in the manufacturing process. These include:

- Setting up, operating, and monitoring various machines, such as extruders, melters, and blenders

- Ensuring that machines are running efficiently and producing high-quality products

- Troubleshooting and resolving any issues that arise with the machinery

- Performing regular maintenance and cleaning of the machines to ensure optimal performance

2. How do you prioritize tasks when working in a fast-paced production environment?

Time Management

- Utilizing time management techniques, such as prioritizing tasks based on urgency and importance

- Delegating responsibilities when appropriate to ensure efficient completion of all tasks

Effective Communication

- Communicating effectively with team members to coordinate tasks and avoid bottlenecks

- Keeping supervisors informed of progress and any challenges encountered

3. Describe the safety protocols you follow when operating heavy machinery.

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs

- Inspecting machinery regularly for any potential hazards or malfunctions

- Following lockout/tagout procedures when performing maintenance or repairs

- Being aware of surroundings and potential hazards in the work area

- Reporting any safety concerns or incidents immediately to supervisors

4. Have you worked with any specific types of plastic molding machines? If so, please describe your experience.

Yes, I have experience working with various types of plastic molding machines, including:

- Injection molding machines

- Blow molding machines

- Extrusion molding machines

In my previous role, I was responsible for operating and maintaining these machines, ensuring they produced high-quality plastic components. I am proficient in setting up, calibrating, and troubleshooting these machines.

5. How do you handle quality control in your work?

- Conducting regular inspections of products throughout the production process

- Using measuring tools and gauges to ensure products meet specifications

- Identifying and correcting any defects or inconsistencies in the products

- Maintaining detailed records of quality control checks and inspections

- Working closely with quality control personnel to ensure adherence to company standards

6. What is your experience with lean manufacturing techniques?

- Implementing 5S principles to maintain a clean and organized work area

- Identifying and eliminating waste in the production process

- Improving efficiency through continuous improvement initiatives

- Collaborating with team members to find innovative solutions to production challenges

7. Describe a situation where you had to troubleshoot a major issue with a production machine. How did you approach the problem and what was the outcome?

In one instance, a critical injection molding machine experienced a sudden malfunction, causing production to halt. I quickly assessed the situation and began troubleshooting the issue.

- Checked electrical connections and power supply

- Inspected mechanical components for any signs of damage or wear

- Consulted technical manuals and sought advice from experienced colleagues

- After thorough investigation, identified a faulty sensor as the root cause

- Replaced the sensor and performed necessary adjustments to restore the machine to full functionality

Through this experience, I demonstrated my problem-solving abilities, technical knowledge, and commitment to resolving production issues efficiently.

8. How do you stay up-to-date with advancements in the plastics industry?

- Attending industry conferences and exhibitions

- Reading trade publications and technical journals

- Participating in online forums and discussion groups

- Seeking professional development opportunities, such as workshops and training programs

9. What are your expectations for this role and how do you believe your skills align with the company’s needs?

In this role, I expect to utilize my technical expertise in operating and maintaining plastic molding machines, contributing to the company’s production goals. I am confident that my skills and experience in:

- Machine setup and operation

- Quality control and troubleshooting

- Safety and compliance

- Lean manufacturing principles

align well with the company’s need for a highly skilled and productive Combination Operator. I am eager to learn more about the company’s specific requirements and contribute to its success.

10. Why are you interested in working as a Combination Operator in our company?

I am drawn to this role at your company because of its reputation as a leader in the plastics industry. I am impressed by the company’s commitment to innovation and quality, which aligns with my own values. I believe that my skills and experience can make a valuable contribution to your team, and I am eager to contribute to the company’s continued success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Combination Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Combination Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Combination Operators, as the name suggests, are responsible for operating multiple types of machines or processes simultaneously. Their key responsibilities encompass a wide range of tasks that ensure the smooth functioning of the production line.

1. Machine Operation and Monitoring

Combination Operators are proficient in operating a variety of machines, including combination machines, packaging machines, and automated systems. They monitor the machines’ performance, adjusting settings, and maintaining optimal operating conditions.

- Operate and monitor multiple machines or processes simultaneously

- Adjust machine settings and parameters to optimize production

- Inspect products for defects and quality control

2. Material Handling and Inventory Management

Combination Operators handle and manage raw materials, work-in-progress, and finished products. They ensure that materials are loaded, unloaded, and stored properly, maintaining inventory levels and minimizing waste.

- Load and unload materials from machines and conveyors

- Maintain inventory levels and identify material shortages

- Monitor and adjust material flow to optimize production efficiency

3. Quality Control and Assurance

Combination Operators are responsible for maintaining high-quality standards in the production process. They inspect products at various stages, ensuring they meet the desired specifications. They also conduct quality checks and implement corrective actions as needed.

- Inspect products for defects and non-conformances

- Implement quality control procedures and monitor process parameters

- Report quality issues and work with supervisors to resolve them

4. Maintenance and Troubleshooting

Combination Operators perform basic maintenance and troubleshooting on the machines they operate. They resolve minor issues, lubricate components, and clean equipment to maintain uptime and productivity.

- Perform routine maintenance and cleaning tasks on equipment

- Troubleshoot minor machine malfunctions and resolve issues

- Report major maintenance issues to supervisors for assistance

Interview Preparation Tips

To ace the interview for a Combination Operator position, it is crucial to prepare thoroughly and showcase your relevant skills and experience. Here are some tips to help you prepare:

1. Research the Company and Position

Familiarize yourself with the company’s history, products or services, and industry standing. Research the Combination Operator role specifically, understanding the responsibilities, qualifications, and expectations.

- Visit the company’s website and social media pages

- Read industry news and articles to understand current trends

- Prepare questions to ask the interviewer about the company and role

2. Highlight Your Relevant Skills and Experience

Emphasize your experience in operating multiple machines or processes simultaneously. Showcase your proficiency in handling materials, maintaining inventory, and ensuring quality standards. Quantify your accomplishments and provide specific examples to demonstrate your abilities.

- Describe your experience with different types of machines and processes

- Highlight your success in optimizing production efficiency and reducing waste

- Provide examples of implementing quality control measures and resolving product defects

3. Practice Answering Common Interview Questions

Anticipate questions related to your technical skills, experience, and problem-solving abilities. Prepare thoughtful answers that showcase your strengths and enthusiasm for the role. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Practice answering questions about your machine operation and troubleshooting skills

- Prepare examples of how you have handled material handling and inventory management challenges

- Be ready to discuss your approach to maintaining high-quality standards and resolving product defects

4. Dress Professionally and Arrive Punctually

First impressions matter, so dress appropriately for the interview. Arrive on time and be prepared to present yourself in a professional and courteous manner. Your appearance and punctuality demonstrate respect for the interviewer and the company.

- Choose business casual or formal attire, depending on the company culture

- Arrive at the interview location a few minutes early

- Be polite and respectful to everyone you encounter, including receptionists and other employees

Next Step:

Now that you’re armed with the knowledge of Combination Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Combination Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini