Are you gearing up for a career in Combination Welder Apprentice? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Combination Welder Apprentice and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

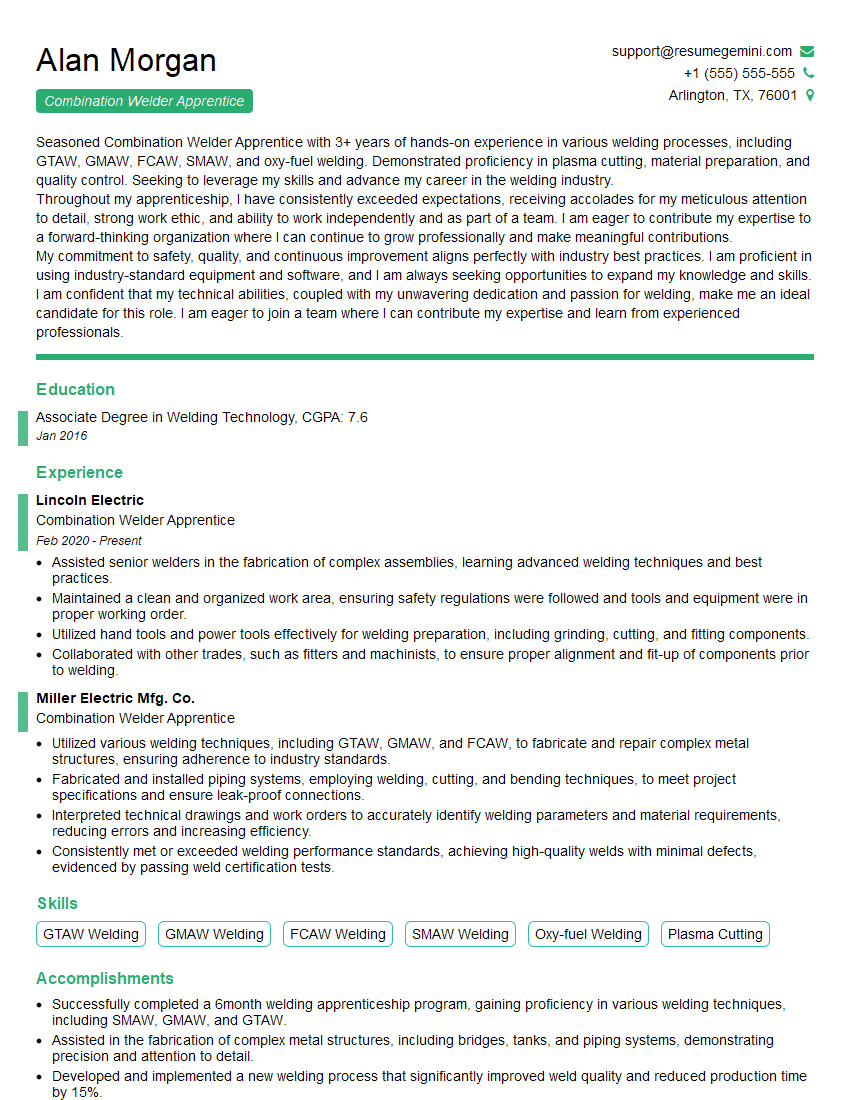

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Combination Welder Apprentice

1. What welding processes are you proficient in, and for which applications?

I have experience in a variety of welding processes, including:

- Shielded Metal Arc Welding (SMAW), also known as stick welding

- Gas Metal Arc Welding (GMAW), also known as MIG welding

- Gas Tungsten Arc Welding (GTAW), also known as TIG welding

- Flux-Cored Arc Welding (FCAW)

I have used these processes in various applications, including:

- Fabrication of structural steel components

- Repair of heavy equipment and machinery

- Construction of pipelines and pressure vessels

2. Can you describe the different types of joints used in welding and what are their applications?

Types of Welded Joints

- Butt joint: This is the simplest type of joint, where two pieces of metal are joined edge-to-edge.

- Edge joint: This joint is formed when two pieces of metal are joined side-by-side.

- T-joint: This joint is formed when one piece of metal is joined to the side of another piece of metal.

- Corner joint: This joint is formed when two pieces of metal are joined at a right angle.

Applications of Welded Joints

- Butt joints are used in applications where strength is critical, such as in structural components.

- Edge joints are used in applications where a smooth surface is required, such as in sheet metal fabrication.

- T-joints are used in applications where two pieces of metal need to be joined at a right angle, such as in the construction of frames.

- Corner joints are used in applications where two pieces of metal need to be joined at a corner, such as in the construction of boxes.

3. What is the importance of proper joint preparation for welding?

- Proper joint preparation is important for ensuring the quality of the weld.

- Improperly prepared joints can lead to defects such as porosity, slag inclusions, and undercut.

- Proper joint preparation also helps to ensure that the weld will be strong and durable.

- The specific requirements for joint preparation will vary depending on the type of welding process being used.

4. How do you ensure the quality of your welds?

- I follow a number of procedures to ensure the quality of my welds.

- I start by inspecting the joint to make sure that it is properly prepared.

- I then select the appropriate welding process and parameters for the material and joint type.

- During welding, I monitor the weld pool and make adjustments as necessary to ensure that the weld is being deposited correctly.

- After welding, I inspect the weld for any defects.

5. What is the difference between a combination welder and a welder?

- Combination welders are skilled in multiple welding processes, while welders are typically proficient in a single process.

- Combination welders are typically more versatile and can work on a wider variety of projects.

- Combination welders are often employed in industries that require a variety of welding skills, such as construction, fabrication, and shipbuilding.

6. What are the advantages of using a combination welder?

- Combination welders are more versatile and can work on a wider variety of projects.

- They are more efficient because they do not have to switch between different welding machines.

- They are more cost-effective because they do not need to purchase multiple welding machines.

7. What are the challenges of working as a combination welder?

- Combination welders need to be proficient in multiple welding processes.

- They need to be able to adapt to different work environments and materials.

- They need to be able to work independently and as part of a team.

8. Why are you interested in becoming a combination welder apprentice?

- I am interested in becoming a combination welder because it is a challenging and rewarding career.

- I am eager to learn new skills and expand my knowledge of welding.

- I believe that my skills and experience would make me a valuable asset to your company.

9. What are your career goals?

- My career goal is to become a certified welder and eventually a welding inspector.

- I also want to gain experience in different industries and work on a variety of projects.

- Ultimately, I would like to start my own welding business.

10. Do you have any questions for me?

- I am interested in learning more about your company and the apprenticeship program.

- Can you tell me more about the training and experience that I can expect as an apprentice?

- What are the opportunities for advancement within the company?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Combination Welder Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Combination Welder Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A combination welder apprentice is a highly skilled tradesman who performs a range of welding tasks under the supervision of an experienced welder. Key job responsibilities include:

1. Welding

Combination welder apprentices must be proficient in various welding techniques, including shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and gas tungsten arc welding (GTAW). They must be able to weld a variety of materials, including steel, aluminum, and stainless steel.

- Interpret welding blueprints and specifications

- Select and set up welding equipment

- Prepare and clean weld surfaces

- Weld according to specified procedures

- Inspect welds for quality

2. Cutting

Combination welder apprentices may also be required to cut metal using a variety of methods, including oxy-fuel cutting, plasma cutting, and laser cutting.

- Operate cutting equipment safely

- Cut metal according to specified dimensions

- Prepare and clean cut surfaces

3. Fabrication

Combination welder apprentices may be involved in the fabrication of metal structures, such as tanks, boilers, and bridges. They may also be required to perform other tasks, such as grinding, fitting, and assembly.

- Read and understand fabrication drawings

- Layout and cut metal components

- Weld and assemble metal components

- Grind and finish welds

- Inspect completed fabrications

4. Safety

Combination welder apprentices must adhere to all safety regulations and procedures. They must be aware of the hazards associated with welding and cutting, and they must take the necessary precautions to protect themselves and others.

- Wear appropriate safety gear

- Follow safe work practices

- Inspect equipment regularly

- Report any safety hazards

Interview Tips

In order to ace an interview for a combination welder apprentice position, it is important to be prepared. Here are a few tips:

1. Research the company and the position

Take some time to learn about the company and the specific position you are applying for. This will help you to answer questions about your qualifications and why you are interested in the job.

- Visit the company website

- Read industry publications

- Talk to people who work in the industry

2. Practice your answers to common interview questions

There are a few common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral questions

- Tailor your answers to the specific job you are applying for

- Be prepared to talk about your skills and experience

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the workplace.

- Wear a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Avoid wearing revealing or casual clothing

4. Be on time

Punctuality is important for any job interview, but it is especially important for a combination welder apprentice position. This shows the interviewer that you are reliable and that you respect their time.

- Plan your route to the interview in advance

- Leave yourself plenty of time to get there

- If you are running late, call the interviewer to let them know

5. Be prepared to talk about your welding experience

If you have any welding experience, be sure to highlight it in your interview. This could include experience from a previous job, a trade school, or a hobby.

- Describe the types of welding you have done

- Discuss your welding skills and abilities

- Provide examples of your welding work

6. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic and positive about their work. Show the interviewer that you are excited about the opportunity to learn and grow as a combination welder apprentice.

- Smile and make eye contact

- Be positive and upbeat in your answers

- Express your interest in the position and the company

Next Step:

Now that you’re armed with the knowledge of Combination Welder Apprentice interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Combination Welder Apprentice positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini