Are you gearing up for a career in Combination Welder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Combination Welder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

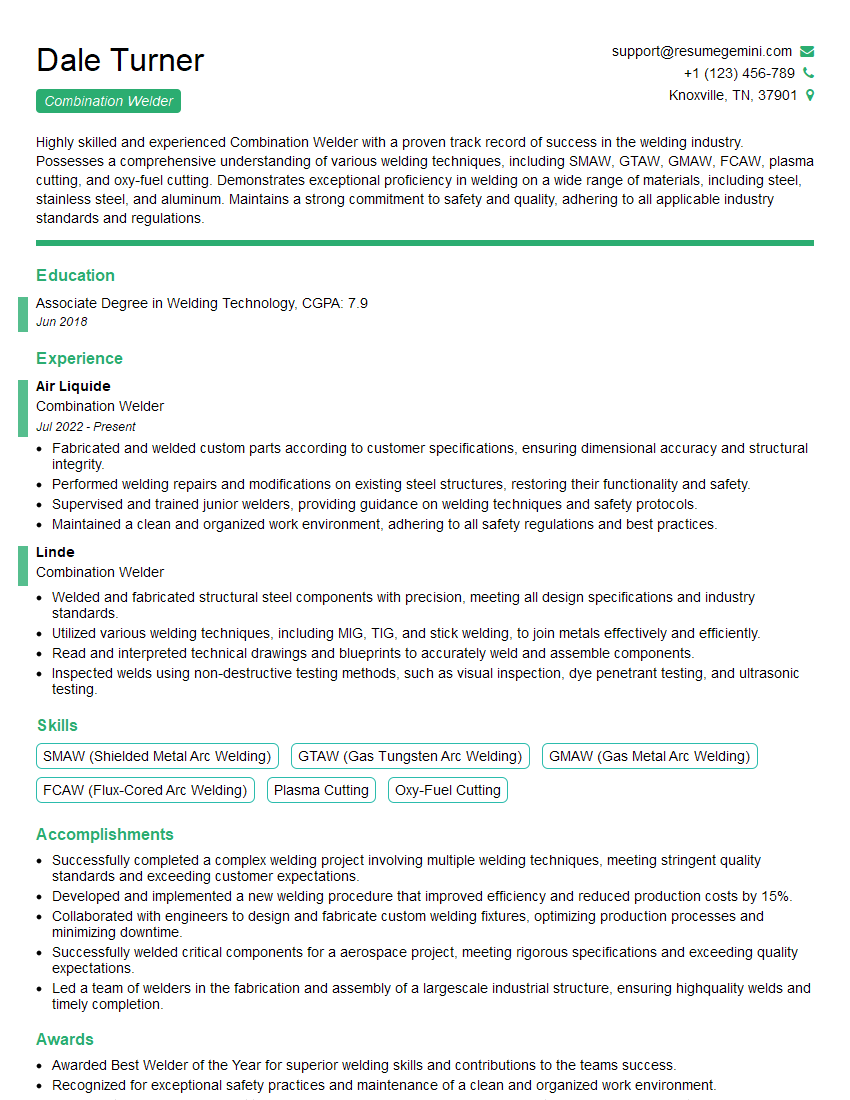

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Combination Welder

1. Describe the process of welding dissimilar metals?

When welding dissimilar metals, several key steps are involved:

- Joint preparation: Ensuring clean and properly prepared joint surfaces is crucial.

- Filler metal selection: Choosing the right filler metal that is compatible with both base metals is essential.

- Welding process selection: Selecting the most suitable welding process (e.g., TIG, MIG, or arc welding) based on the metals and joint design is critical.

- Welding parameters optimization: Adjusting welding parameters (e.g., heat input, travel speed, and shielding gas) to achieve optimal weld quality and strength.

- Post-weld treatment: Applying appropriate post-weld treatments (e.g., heat treatment or stress relieving) can enhance the joint’s properties as needed.

2. What are the different types of welding joints?

Butt Joints

- Square butt joint

- Bevel butt joint

- V-butt joint

- U-butt joint

Edge Joints

- T-joint

- Corner joint

- Edge joint

Lap Joints

- Single-lap joint

- Double-lap joint

3. Explain the different welding positions?

There are four main welding positions:

- Flat position: Welding on a horizontal surface, with the welder in a comfortable position.

- Horizontal position: Welding on a vertical surface, with the welder facing the joint.

- Vertical position: Welding on a vertical surface, with the welder positioned below the joint.

- Overhead position: Welding on a surface above the welder, requiring special techniques and equipment.

4. What are the common welding defects and how to prevent them?

- Porosity: Caused by gas entrapment, can be prevented by ensuring proper shielding gas coverage and using clean materials.

- Cracks: Caused by excessive stresses or rapid cooling, can be prevented by preheating, using appropriate welding techniques, and post-weld heat treatment.

- Undercut: Caused by excessive heat input, can be prevented by adjusting welding parameters and using proper joint preparation.

- Incomplete fusion: Caused by insufficient heat input, can be prevented by increasing heat input or adjusting travel speed.

- Slag inclusions: Caused by incomplete removal of slag, can be prevented by proper cleaning of the joint and using appropriate fluxes.

5. What are the safety precautions to be taken when welding?

- Wearing appropriate protective gear (welding helmet, gloves, apron, and respirator)

- Ensuring proper ventilation to avoid exposure to welding fumes

- Inspecting equipment regularly for any damages or malfunctions

- Storing and handling welding materials safely

- Following established safety protocols and guidelines

6. Describe the different welding codes and standards?

There are various welding codes and standards established by different organizations to ensure the quality and safety of welded structures. Some common codes include:

- AWS D1.1: Structural Welding Code – Steel

- AWS D1.2: Structural Welding Code – Aluminum

- API 1104: Welding of Pipelines and Related Facilities

- ASME Boiler and Pressure Vessel Code: Section IX: Welding and Brazing Qualifications

- ISO 3834: Quality Requirements for Fusion Welding of Metallic Materials

7. What is the difference between TIG and MIG welding?

- TIG welding (GTAW): Uses a non-consumable tungsten electrode, provides precise control, and is ideal for thin materials.

- MIG welding (GMAW): Uses a continuously fed consumable wire electrode, offers high deposition rates, and is suitable for thicker materials.

8. What are the advantages and disadvantages of using flux-cored arc welding (FCAW)?

Advantages

- High deposition rates

- Good weld penetration

- Less spatter compared to MIG welding

- Self-shielding capability (in some cases)

Disadvantages

- Fume generation

- Slag removal required

- Limited visibility of the weld pool

9. Describe the process of brazing and soldering?

Brazing: A metal-joining process that uses a filler metal with a lower melting point than the base metals. The filler metal melts and flows into the joint, creating a strong bond.

Soldering: Similar to brazing, but uses a filler metal with an even lower melting point. Soldering is used to join electrical components or for sealing purposes.

10. What are the different types of welding equipment?

- Welding machines: Power sources that provide the electrical current for welding.

- Welding torches: Hand-held devices that direct the shielding gas and welding wire (in the case of MIG/TIG welding).

- Welding electrodes: Consumable or non-consumable metal rods that conduct electricity and create the weld pool.

- Shielding gases: Inert or active gases used to protect the weld pool from atmospheric contamination.

- Welding accessories: Clamps, positioners, and other tools used to support and manipulate the workpiece during welding.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Combination Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Combination Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Combination Welders are responsible for a wide range of welding tasks using various welding techniques, including gas welding, arc welding, and resistance welding. They play a crucial role in the fabrication, maintenance, and repair of metal structures and components in various industries, including automotive, construction, and manufacturing.

1. Welding Techniques and Equipment

Combination Welders must have proficiency in various welding techniques, such as arc welding (e.g., TIG, MIG, flux-cored), gas welding (e.g., oxy-acetylene), and resistance welding (e.g., spot welding). They should be skilled in using different welding equipment, including welding machines, torches, and protective gear.

2. Material and Fabrication

They work with various metals, such as steel, stainless steel, and aluminum, and understand their properties and characteristics. They prepare metal surfaces for welding, including cleaning, grinding, and beveling. Combination Welders follow blueprints, drawings, and specifications to fabricate, assemble, and repair metal structures and components.

3. Safety and Quality Control

Combination Welders are responsible for maintaining a safe work environment by adhering to safety regulations and guidelines. They follow established welding standards and quality control procedures to ensure the integrity and reliability of welded structures. They conduct inspections and tests to verify the quality of their work.

4. Communication and Collaboration

They work closely with other professionals, such as engineers, designers, and inspectors. Effective communication and collaboration skills are essential for understanding project requirements, coordinating with team members, and resolving any issues. Combination Welders may also provide guidance and training to apprentices and less experienced welders.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Combination Welder position:

1. Research the Company and Role

Before the interview, take the time to research the company you’re applying to and the specific role you’re interested in. Understanding their business, industry, and the requirements of the position will demonstrate your interest and preparedness.

2. Practice Your Welding Techniques

If possible, practice your welding skills before the interview. This will help you feel confident in your abilities and demonstrate your proficiency during any practical tests or questions related to your welding techniques.

3. Highlight Your Experience and Skills

Emphasize your experience and skills that are relevant to the job responsibilities. Quantify your accomplishments whenever possible, using specific examples to showcase your contributions and impact. Use the STAR method (Situation, Task, Action, Result) to structure your answers.

4. Safety and Quality Control Knowledge

Highlight your understanding of safety regulations and quality control procedures. Showcase your commitment to maintaining a safe work environment and ensuring the integrity of your work. Explain how you adhere to established standards and perform inspections to verify the quality of your welds.

Next Step:

Now that you’re armed with the knowledge of Combination Welder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Combination Welder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini