Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Combining Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Combining Machine Operator so you can tailor your answers to impress potential employers.

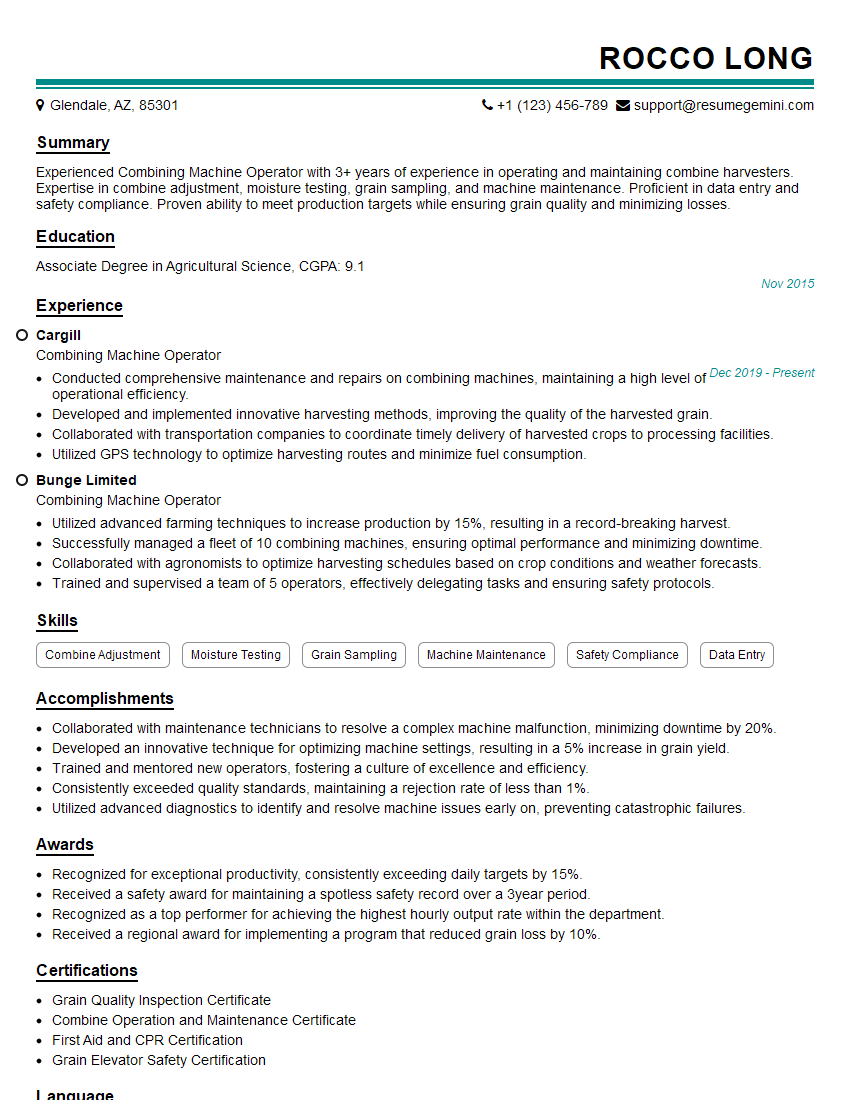

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Combining Machine Operator

1. Explain the key components of a combine harvester and their functions?

- Header: The header is the front-most component of the combine and is responsible for cutting and gathering the crop.

- Threshing unit: The threshing unit separates the grain from the straw and chaff. It consists of a cylinder and concave, which rub against each other to break open the seed heads and release the grain.

- Cleaning unit: The cleaning unit removes any remaining straw, chaff, and other impurities from the grain. It consists of a series of screens and fans that separate the grain by size and weight.

- Grain tank: The grain tank stores the cleaned grain until it can be unloaded into a truck or trailer.

- Engine and transmission: The engine provides power to the combine’s various components, and the transmission transfers power from the engine to the wheels and other moving parts.

2. Describe the process of operating a combine harvester?

Pre-harvest preparation

- Inspect the combine and make sure all components are in good working order.

- Set the header height and cutting width to match the crop conditions.

- Calibrate the combine’s sensors to ensure accurate yield monitoring.

Harvesting

- Drive the combine through the field, following the crop rows.

- Monitor the combine’s performance and make adjustments as needed to optimize grain quality and yield.

- Unload the grain tank into a truck or trailer when it is full.

Post-harvest maintenance

- Clean the combine thoroughly to remove any remaining crop residue.

- Inspect the combine for any damage or wear and tear.

- Store the combine in a dry, protected location until the next harvest season.

3. What are the factors that affect the efficiency of a combine harvester?

- Crop conditions: The type of crop, its maturity, and the field conditions can all affect the combine’s efficiency.

- Combine settings: The header height, cutting width, and threshing speed must be set correctly to optimize grain quality and yield.

- Operator skill: The operator’s skill and experience can also affect the combine’s efficiency.

- Weather conditions: Rain, wind, and dust can all slow down the combine’s progress and reduce its efficiency.

4. How do you troubleshoot common problems that occur with combine harvesters?

- Poor grain quality: This can be caused by a variety of factors, such as incorrect header settings, a worn threshing cylinder, or a dirty cleaning unit.

- Reduced yield: This can be caused by a variety of factors, such as incorrect header settings, a slow threshing speed, or a clogged cleaning unit.

- Mechanical breakdowns: These can be caused by a variety of factors, such as worn belts, leaking hydraulics, or electrical problems.

5. What are the safety precautions that must be taken when operating a combine harvester?

- Always wear appropriate safety gear, such as a hard hat, safety glasses, and gloves.

- Inspect the combine thoroughly before each use to identify any potential hazards.

- Never operate the combine near power lines or other overhead obstructions.

- Be aware of your surroundings and watch for other people and vehicles.

- Never attempt to repair or adjust the combine while it is running.

6. What are the maintenance procedures that must be performed on a combine harvester?

- Daily maintenance: This includes tasks such as cleaning the combine, checking the oil and hydraulic fluid levels, and greasing the moving parts.

- Weekly maintenance: This includes tasks such as checking the belts and chains, inspecting the tires, and cleaning the air filter.

- Monthly maintenance: This includes tasks such as changing the oil and filters, inspecting the brakes, and checking the electrical system.

- Seasonal maintenance: This includes tasks such as preparing the combine for storage at the end of the season and inspecting it before the start of the next season.

7. How do you calculate the yield of a combine harvester?

- The yield of a combine harvester is calculated by dividing the weight of the grain harvested by the area of the field harvested.

- The weight of the grain is measured using a grain scale.

- The area of the field is measured using a GPS system or a measuring wheel.

8. What are the different types of combine harvesters?

- Self-propelled combines: These combines are self-powered and can move around the field under their own power.

- Pull-type combines: These combines are towed behind a tractor.

- Grain carts: Grain carts are used to collect the grain from the combine and transport it to a storage facility.

9. What are the advantages and disadvantages of using a combine harvester?

Advantages

- Combines are efficient and can harvest large areas of land in a short amount of time.

- Combines are versatile and can be used to harvest a variety of crops.

- Combines are relatively easy to operate and maintain.

Disadvantages

- Combines are expensive to purchase and operate.

- Combines can be damaged if they are not operated properly.

- Combines can be dangerous to operate if they are not used safely.

10. What are the future trends in combine harvester technology?

- Increased use of automation: Combine harvesters are becoming increasingly automated, with features such as automatic steering and yield mapping.

- Improved efficiency: Combine harvesters are becoming more efficient, with features such as variable-speed transmissions and improved threshing systems.

- Reduced environmental impact: Combine harvesters are becoming more environmentally friendly, with features such as reduced emissions and improved fuel efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Combining Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Combining Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities:

The Combining Machine Operator plays a vital role in harvesting operations by expertly operating combine harvesters to separate and collect crops. The key job responsibilities include:

1. Combine Operation

Operate Combine Harvester:

- Expertly navigate and control the combine harvester during harvesting operations.

- Monitor machine settings and adjust them as needed to optimize performance and minimize grain loss.

- Ensure smooth operation and timely repairs of the combine harvester.

2. Grain Handling

Ensure efficient grain handling:

- Monitor grain flow and adjust harvester settings to prevent blockages and reduce grain damage.

- Supervise grain unloading from the harvester into transport vehicles, ensuring minimal spillage and grain quality.

- Control grain loading rate and monitor grain moisture levels.

3. Field Maintenance

Maintain field conditions for efficient harvesting:

- Monitor crop yield and field conditions to determine harvesting strategies.

- Communicate with farmers and other operators to coordinate harvesting schedules and field preparation.

- Ensure proper preparation of fields, including cutting swaths and removing obstacles.

4. Quality Control

Enforce quality standards for harvested crops:

- Inspect harvested grain for quality and identify any potential issues, such as contamination or damage.

- Comply with food safety regulations and maintain high standards of hygiene during harvesting operations.

Interview Tips:

To ace the interview for a Combining Machine Operator position, it is essential to:

1. Research the Company and Role

Understand the company’s background, operations, and the specific responsibilities of the Combining Machine Operator role. This will demonstrate your interest and preparation.

- Visit the company website, social media pages, and industry news sources.

- Review the job description thoroughly and identify key skills and experience required.

2. Practice Common Interview Questions

Prepare for common interview questions related to combine operation, grain handling, field maintenance, and quality control. Anticipate technical questions and be ready to explain your expertise.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your experience.

- Consider questions such as “Describe a time you faced a challenge while operating a combine harvester” or “How do you maintain quality standards for harvested crops?”

3. Highlight Relevant Experience and Skills

Emphasize your experience in operating combine harvesters and handling grain. Quantify your accomplishments and demonstrate your ability to meet performance targets.

- Provide details about the types of combine harvesters you have operated and the crops you have harvested.

- Describe your understanding of grain quality standards and how you ensure compliance.

4. Be Enthusiastic and Confident

Convey your enthusiasm for working in agriculture and your passion for operating combine harvesters. Express confidence in your abilities and willingness to learn and grow in the role.

- Share your experiences that demonstrate your commitment to agriculture and your interest in the industry.

- Maintain eye contact, speak clearly, and project a positive attitude throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Combining Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.