Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Commutator Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Commutator Assembler so you can tailor your answers to impress potential employers.

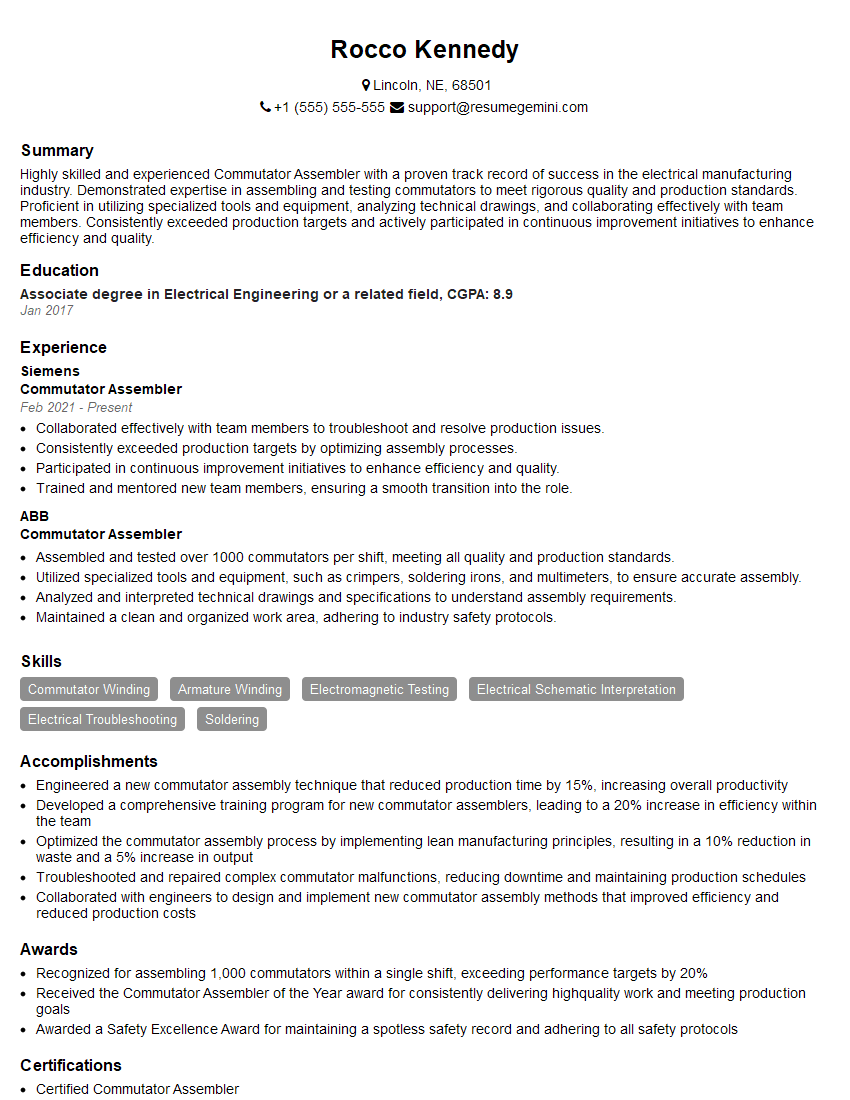

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Commutator Assembler

1. Explain the process of assembling a commutator from start to finish?

To assemble commutator,I would follow these steps:

- Inspect the commutator components, including the segments, risers, and mica.

- Clean and prepare the commutator segments by removing any burrs or imperfections.

- Assemble the commutator segments onto the mica former, ensuring proper alignment and spacing.

- Install the risers between the commutator segments to create the electrical connections.

- Insulate the commutator using mica or other insulating material to prevent electrical shorts.

- Connect the commutator to the armature or other electrical components using solder or other appropriate methods.

- Test the commutator for electrical continuity and insulation resistance to ensure proper functionality.

2. What are the different types of commutators used in electric motors?

Types of Commutators

- Unturned Commutators

- Formed Commutators

- Molded Commutators

- Fabricated Commutators

Description

- Unturned Commutators: Made from a single piece of copper, no turning operation is required.

- Formed Commutators: Made from a copper strip, formed into a cylindrical shape and then cut into segments.

- Molded Commutators: Made from a plastic material, with the copper segments molded in.

- Fabricated Commutators: Made by assembling individual copper segments and risers.

3. What are the key factors to consider when selecting the right commutator for a particular application?

When selecting the right commutator for a particular application, several key factors should be considered:

- Motor type and operating conditions (speed, voltage, current)

- Size and shape of the armature

- Number of segments and risers required

- Material and conductivity of the commutator segments

- Insulating materials used

- Cost and availability

4. How do you ensure the accuracy and precision of the commutator assembly process?

To ensure the accuracy and precision of the commutator assembly process, I would implement the following measures:

- Use precision tools and measuring equipment

- Follow established assembly procedures and specifications

- Inspect components and assemblies at each stage of the process

- Perform electrical testing to verify proper functionality

- Continuously monitor and improve the assembly process

5. What are the common challenges faced during commutator assembly, and how do you overcome them?

Challenges

- Alignment and spacing of commutator segments

- Insulating the commutator to prevent electrical shorts

- Soldering or connecting the commutator to other components

- Testing and troubleshooting electrical issues

Overcoming Challenges

- Use precision tools and techniques for accurate assembly

- Apply appropriate insulating materials and techniques

- Follow established soldering or connection procedures

- Perform thorough electrical testing and troubleshooting

6. How do you stay up-to-date with the latest advancements in commutator assembly and electric motor technology?

To stay up-to-date with the latest advancements in commutator assembly and electric motor technology, I actively engage in the following:

- Attend industry conferences and workshops

- Read technical journals and publications

- Participate in online forums and discussions

- Collaborate with experts in the field

- Research and explore new technologies and materials

7. What are the safety precautions you take when working with commutators and electric motors?

When working with commutators and electric motors, I prioritize the following safety precautions:

- Wear appropriate personal protective equipment (PPE)

- Ensure proper grounding and isolation of electrical components

- Follow lockout/tagout procedures before performing maintenance

- Handle commutators and motors with care to avoid damage

- Be aware of potential electrical hazards and take steps to mitigate them

8. What is the role of a commutator in an electric motor, and how does it contribute to the motor’s operation?

A commutator in an electric motor plays a crucial role in converting alternating current (AC) into direct current (DC). It consists of a set of copper segments insulated from each other and connected to the armature windings.

- As the motor operates, the commutator ensures that the current flows through the armature windings in a specific sequence.

- This controlled current flow creates a rotating magnetic field that interacts with the stator’s magnetic field, resulting in the motor’s rotation.

9. Can you describe the different types of materials used in the construction of commutators and their respective advantages and disadvantages?

Materials and their Characteristics

- Copper: Excellent electrical conductivity, but prone to wear and oxidation

- Silver: High conductivity and corrosion resistance, but expensive

- Graphite: Self-lubricating and durable, but lower conductivity

- Precious metals (e.g., gold, platinum): Exceptional conductivity and wear resistance, but very expensive

- Composites: Combinations of materials to achieve specific properties, such as high conductivity and wear resistance

10. What quality control measures do you implement to ensure the reliability and durability of commutators you assemble?

To ensure the reliability and durability of commutators, I implement the following quality control measures:

- Inspection of incoming materials and components

- Adherence to established assembly procedures and specifications

- In-process inspections at critical stages of assembly

- Electrical testing to verify insulation resistance and continuity

- Final inspection and testing before shipment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Commutator Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Commutator Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Commutator Assembler is a skilled professional responsible for the assembly and testing of commutators, essential components in electric motors and generators. They play a crucial role in ensuring the smooth operation of these devices.

1. Commutator Assembly

The primary responsibility of a Commutator Assembler is to assemble commutators according to specified designs and specifications.

- Properly position and secure commutator segments on the armature core.

- Accurately align and solder commutator segments to ensure electrical conductivity.

2. Component Inspection

Commutator Assemblers must carefully inspect all components before assembly.

- Verify the dimensions and tolerances of commutator segments and other components.

- Examine for any defects, cracks, or imperfections that could affect performance.

3. Testing and Adjustment

Upon assembly, Commutator Assemblers conduct thorough testing to ensure the commutator meets required specifications.

- Perform electrical continuity tests to check for proper connections and conductivity.

- Make necessary adjustments to optimize commutator performance, such as adjusting brush alignment.

4. Quality Control

Commutator Assemblers are responsible for maintaining high quality standards.

- Adhere to established quality control procedures and documentation.

- Identify and correct any deviations from specifications or customer requirements.

Interview Tips

Preparing for an interview can significantly increase your chances of success. Here are some tips to help you ace your Commutator Assembler interview:

1. Research the Company and Position

Thoroughly research the company you’re applying to and the specific Commutator Assembler role. Understand their business, products, and the requirements of the position.

- Visit the company’s website to learn about their history, mission, and values.

- Read industry-related articles and publications to stay up-to-date on advancements and trends.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your skills and experience.

- Describe your experience in commutator assembly and testing.

- Explain your understanding of the importance of quality control in commutator manufacturing.

3. Highlight Your Technical Skills

Emphasize your technical skills and knowledge in commutator assembly, including:

- Soldering and welding techniques.

- Electrical testing and troubleshooting.

- Knowledge of commutator design and materials.

4. Showcase Your Problem-Solving Abilities

Provide examples of how you have successfully solved problems or overcome challenges in previous roles.

- Describe a situation where you identified and resolved a defect in a commutator assembly.

- Explain how you optimized the efficiency of a commutator testing process.

5. Prepare Questions for the Interviewer

Asking thoughtful questions shows that you’re engaged and interested in the position. Consider asking about:

- The company’s future plans and growth strategies.

- Opportunities for professional development and advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Commutator Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!