Feeling lost in a sea of interview questions? Landed that dream interview for Compacting Machine Operator/Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Compacting Machine Operator/Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

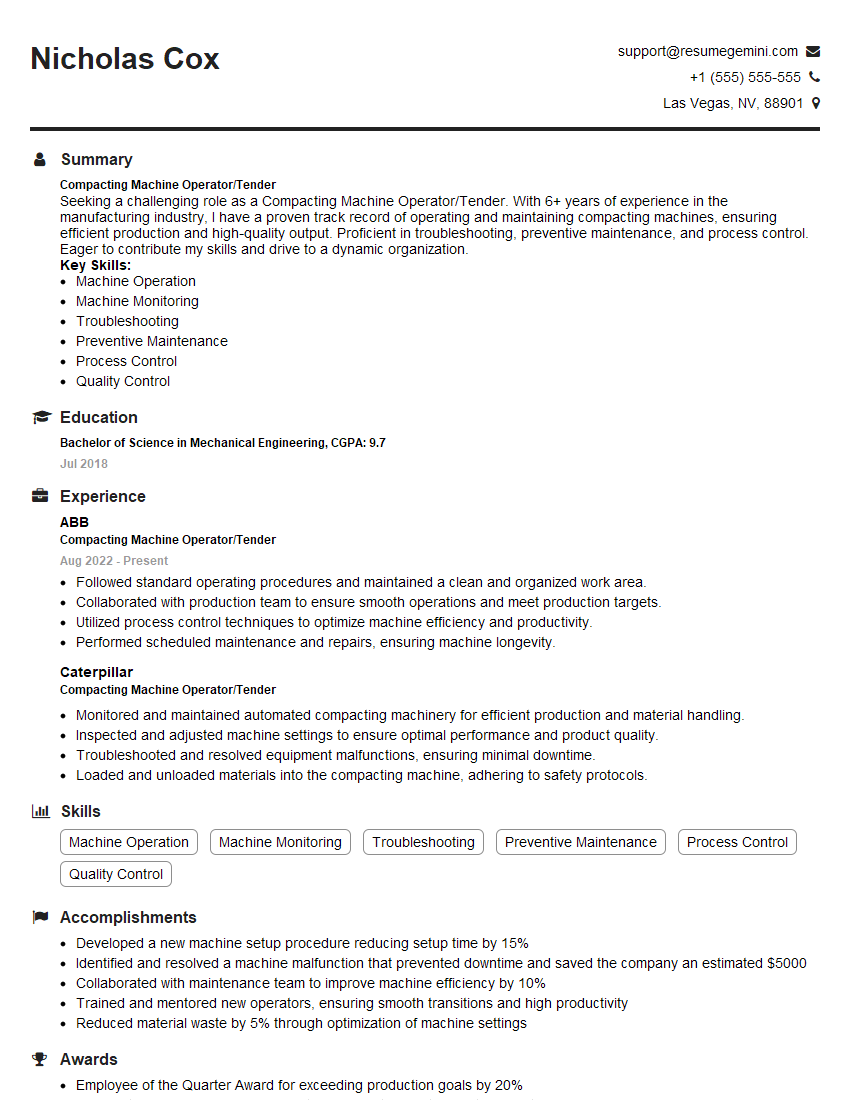

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compacting Machine Operator/Tender

1. Explain the process of operating a compacting machine?

The process of operating a compacting machine involves the following steps:

- Loading the material into the hopper

- Setting the compaction force and other parameters

- Starting the machine and allowing it to compact the material

- Unloading the compacted material

2. What are the different types of compacting machines and their applications?

Soil Compacting Machines

- Used to compact soil for construction projects, such as roads, bridges, and buildings.

Asphalt Compacting Machines

- Used to compact asphalt for paving roads and parking lots.

Concrete Compacting Machines

- Used to compact concrete for construction projects, such as buildings, bridges, and dams.

3. How do you determine the correct compaction force for a given material?

The correct compaction force for a given material depends on the type of material, its moisture content, and the desired level of compaction.

- For soil, the compaction force is typically determined using a Proctor test.

- For asphalt, the compaction force is typically determined using a Marshall test.

4. What are the common problems that can occur when operating a compacting machine and how do you troubleshoot them?

- Engine problems: These can be caused by a variety of factors, such as low oil levels, clogged fuel filters, or spark plug problems.

- Hydraulic problems: These can be caused by leaks in the hydraulic system, worn-out seals, or contamination of the hydraulic fluid.

- Electrical problems: These can be caused by loose connections, faulty wiring, or blown fuses.

5. What are the safety precautions that you must observe when operating a compacting machine?

- Wear appropriate safety gear, such as a hard hat, safety glasses, and gloves.

- Be aware of your surroundings and keep a safe distance from other people and objects.

- Never operate a compacting machine under the influence of alcohol or drugs.

- Follow all manufacturer’s instructions for the safe operation of the machine.

6. What is the importance of regular maintenance for a compacting machine?

Regular maintenance is essential for keeping a compacting machine running smoothly and safely.

- Regular maintenance can help to prevent breakdowns and costly repairs.

- It can also help to extend the life of the machine.

7. How do you maintain the compaction machine on a daily basis?

- Check the oil and hydraulic fluid levels.

- Inspect the belts and hoses for wear and tear.

- Clean the machine of any dirt or debris.

- Tighten any loose bolts or nuts.

8. How do you calibrate the compaction machine?

The calibration of the compaction machine is done by using a calibration block.

- Place the calibration block under the compaction head.

- Set the compaction force to the desired value.

- Compact the calibration block for a specified number of passes.

- Measure the thickness of the compacted block.

- Adjust the compaction force as necessary to achieve the desired compaction.

9. How do you determine the moisture content of soil?

The moisture content of soil can be determined using a soil moisture meter.

- Insert the soil moisture meter into the soil.

- Read the moisture content value on the meter’s display.

10. What is the difference between static and dynamic compaction?

- Static compaction is a process in which the compaction force is applied to the soil without any vibration.

- Dynamic compaction is a process in which the compaction force is applied to the soil with vibration.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compacting Machine Operator/Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compacting Machine Operator/Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Compacting Machine Operator/Tender is responsible for operating, monitoring, and maintaining a variety of compacting machines used in the production of various materials. Their primary duties include:1. Machine Operation

Operate compacting machines to compress, shape, and mold materials according to specifications.

- Adjust machine settings to achieve desired compaction levels and dimensions.

- Monitor machine performance and make adjustments as necessary to optimize efficiency.

2. Material Handling

Load and unload materials into and out of compacting machines.

- Inspect materials for defects and ensure their suitability for compaction.

- Handle and transport materials safely and efficiently.

3. Machine Maintenance

Perform basic maintenance and troubleshooting of compacting machines.

- Clean and lubricate machines to prevent breakdowns.

- Identify and resolve minor malfunctions, such as blockages or leaks.

4. Quality Control

Inspect compacted materials to ensure they meet specifications.

- Measure and record compaction data to track quality and identify any deviations.

- Report any defects or non-conformities to supervisors.

Interview Tips and Hacks

To prepare for an interview as a Compacting Machine Operator/Tender, follow these tips:1. Research the Company and Industry

Learn about the company’s products, processes, and industry trends.

- Highlight your knowledge of compacting techniques and equipment.

- Research the specific compacting machines you may be operating in the role.

2. Emphasize Your Skills and Experience

Highlight your skills in operating and maintaining compacting machines.

- Quantify your experience by providing specific examples of your accomplishments.

- If you have experience with different types of compacting machines, mention them.

3. Talk About Your Safety Consciousness

Emphasize your commitment to safety in the workplace.

- Discuss your experience with safety protocols and regulations.

- Provide examples of how you have ensured the safe operation of compacting machines.

4. Be Prepared to Answer Technical Questions

Be prepared to answer questions about compacting techniques, machine operation, and maintenance.

- Review the basics of compaction and different methods.

- Practice troubleshooting common problems associated with compacting machines.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Compacting Machine Operator/Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!