Are you gearing up for an interview for a Completion Engineer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Completion Engineer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

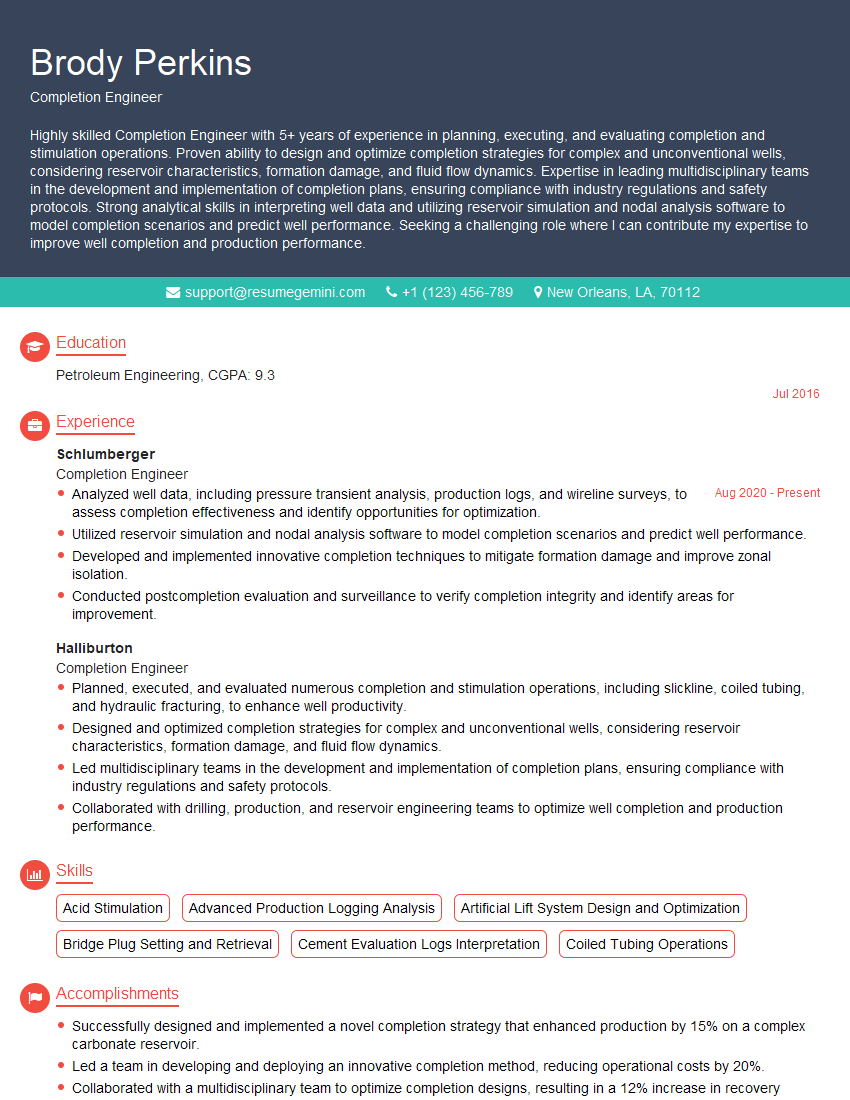

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Completion Engineer

1. What are the key responsibilities of a Completion Engineer?

The key responsibilities of a Completion Engineer include:

- Design and plan well completion programs, including casing, tubing, and packer selection and placement.

- Coordinate with drilling, production, and reservoir engineering teams to ensure that well completions meet operational and production objectives.

- Supervise and manage the installation and operation of well completion equipment, including artificial lift systems.

- Evaluate well performance and recommend remedial actions to optimize production.

- Stay abreast of new technologies and techniques in well completion and optimization.

2. What are the different types of well completion methods?

- Open-hole completions: In this type of completion, the wellbore is not cased or lined, and the formation is exposed to the wellbore fluids.

- Cased-hole completions: In this type of completion, the wellbore is cased or lined, and the formation is isolated from the wellbore fluids.

- Perforated completions: In this type of completion, the casing or liner is perforated, and the formation is exposed to the wellbore fluids through the perforations.

- Gravel-packed completions: In this type of completion, the perforated interval is filled with gravel to prevent sand production.

- Frac-packed completions: In this type of completion, the perforated interval is filled with a proppant to create a high-permeability pathway for the hydrocarbons to flow.

3. What are the factors that should be considered when designing a well completion program?

The factors that should be considered when designing a well completion program include:

- The reservoir characteristics, such as the porosity, permeability, and fluid content.

- The wellbore conditions, such as the depth, temperature, and pressure.

- The production objectives, such as the desired production rate and the anticipated fluid composition.

- The economic considerations, such as the cost of the completion and the expected return on investment.

4. What are the different types of artificial lift systems?

- Gas lift: In this type of system, gas is injected into the wellbore to reduce the hydrostatic pressure and allow the hydrocarbons to flow to the surface.

- Electric submersible pumps (ESPs): In this type of system, a submersible pump is installed in the wellbore to lift the hydrocarbons to the surface.

- Progressive cavity pumps (PCPs): In this type of system, a helical rotor is used to lift the hydrocarbons to the surface.

- Rod pumps: In this type of system, a string of sucker rods is used to reciprocate a plunger in the wellbore, which lifts the hydrocarbons to the surface.

- Hydraulic jet pumps: In this type of system, a high-pressure fluid is injected into the wellbore to create a jet that lifts the hydrocarbons to the surface.

5. What are the advantages and disadvantages of different artificial lift systems?

The advantages and disadvantages of different artificial lift systems include:

- Gas lift: Advantages include low cost and ease of operation. Disadvantages include limited lift capacity and potential for gas locking.

- ESPs: Advantages include high lift capacity and ability to handle a wide range of fluid compositions. Disadvantages include high cost and potential for mechanical failure.

- PCPs: Advantages include high lift capacity and ability to handle a wide range of fluid compositions. Disadvantages include high cost and potential for mechanical failure.

- Rod pumps: Advantages include low cost and ease of operation. Disadvantages include limited lift capacity and potential for mechanical failure.

- Hydraulic jet pumps: Advantages include high lift capacity and ability to handle a wide range of fluid compositions. Disadvantages include high cost and potential for mechanical failure.

6. What is the purpose of a frac pack?

The purpose of a frac pack is to create a high-permeability pathway for the hydrocarbons to flow from the formation to the wellbore. This is achieved by pumping a slurry of proppant into the perforated interval and then applying pressure to the slurry to fracture the formation and create a propped fracture.

7. What are the different types of frac packs?

- Conventional frac packs: In this type of frac pack, the proppant is pumped into the perforated interval before the frac job is performed.

- Perf and frac: In this type of frac pack, the perforated interval is first fractured, and then the proppant is pumped into the fracture.

- Straddle frac packs: In this type of frac pack, a straddle packer is used to isolate the perforated interval, and then the frac job is performed.

8. What are the advantages and disadvantages of different frac pack types?

The advantages and disadvantages of different frac pack types include:

- Conventional frac packs: Advantages include lower cost and higher proppant concentration. Disadvantages include the risk of proppant settling out before the frac job is performed.

- Perf and frac: Advantages include the ability to place the proppant in the fracture where it is needed. Disadvantages include the risk of screenout and the potential for damage to the formation.

- Straddle frac packs: Advantages include the ability to isolate the perforated interval and to control the frac height. Disadvantages include the higher cost and the potential for mechanical failure.

9. What are the different techniques used to evaluate well performance?

- Production testing: Production testing involves flowing the well at different rates and measuring the production data, such as the flow rate, pressure, and fluid composition.

- Well logging: Well logging involves running a logging tool into the wellbore to measure various properties of the formation and the wellbore, such as the porosity, permeability, and fluid saturations.

- Pressure transient analysis: Pressure transient analysis involves analyzing the pressure data from a well test to determine the reservoir properties and the wellbore conditions.

- Numerical simulation: Numerical simulation involves using a computer model to simulate the flow of fluids in the reservoir and the wellbore.

10. What are the most common problems encountered during well completions and how can they be mitigated?

The most common problems encountered during well completions include:

- Stuck pipe: Stuck pipe can occur when the drillstring or casing becomes stuck in the wellbore. This can be mitigated by using proper drilling and completion practices, such as using the correct weight and size of pipe, and by using lubricants and drilling fluids.

- Lost circulation: Lost circulation can occur when the drilling fluid or completion fluid is lost to the formation. This can be mitigated by using lost circulation materials, such as LCM pills and bridging agents.

- Screenout: Screenout can occur when the proppant used in a frac pack bridges off the perforations. This can be mitigated by using the correct proppant size and concentration, and by using a frac fluid that is compatible with the formation and the proppant.

- Formation damage: Formation damage can occur when the drilling or completion fluids damage the formation. This can be mitigated by using drilling and completion fluids that are compatible with the formation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Completion Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Completion Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Completion Engineer is responsible for planning, designing, and executing the completion of oil and gas wells. They work closely with other engineers, geologists, and drilling crews to ensure that the well is completed safely and efficiently.

1. Plan and Design Well Completions

Completion Engineers begin by planning and designing the well completion. This includes determining the type of completion, the materials to be used, and the procedures to be followed.

- Select the type of completion, such as openhole, cased-hole, or gravel pack.

- Design the completion string, including the casing, liner, tubing, and accessories.

- Develop drilling and completion plans.

2. Supervise Well Completion Operations

Once the well completion plan has been finalized, the Completion Engineer supervises the execution of the operations. This includes overseeing the drilling, casing, and cementing operations.

- Supervise the drilling of the well.

- Supervise the installation of the casing and liner.

- Supervise the cementing of the casing and liner.

3. Evaluate Well Completion Performance

Once the well has been completed, the Completion Engineer evaluates its performance. This includes monitoring the production of the well and identifying any potential problems.

- Monitor the production of the well.

- Identify any potential problems with the well.

- Recommend solutions to any problems with the well.

4. Maintain Well Completion Records

The Completion Engineer is responsible for maintaining records of all well completion activities. This includes the drilling, casing, cementing, and production data.

- Maintain records of all drilling activities.

- Maintain records of all casing and cementing activities.

- Maintain records of all production data.

Interview Tips

Preparing for a Completion Engineer interview can be daunting, but following some simple tips can help you increase your chances of success.

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you understand the company’s culture and values, and it will also help you tailor your answers to the specific requirements of the job.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work for the company, if possible.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Make a list of common interview questions.

- Prepare your answers to these questions.

- Practice answering your questions out loud.

3. Prepare Questions for the Interviewer

Asking questions at the end of an interview shows that you’re interested in the position and that you’ve done your research. It’s also a good way to learn more about the company and the position.

- Prepare a list of questions to ask the interviewer.

- Ask questions about the company, the position, and the industry.

- Avoid asking questions that are too personal or that could be perceived as negative.

4. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing a suit or business casual attire. Avoid wearing clothing that is too revealing or too casual.

- Wear a suit or business casual attire.

- Avoid wearing clothing that is too revealing or too casual.

- Make sure your clothes are clean and pressed.

5. Be Yourself

The most important thing is to be yourself during your interview. Don’t try to be someone you’re not, because the interviewer will be able to tell. Just be confident in your abilities and let your personality shine through.

- Be yourself.

- Don’t try to be someone you’re not.

- Be confident in your abilities and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Completion Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!