Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Compo Caster interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Compo Caster so you can tailor your answers to impress potential employers.

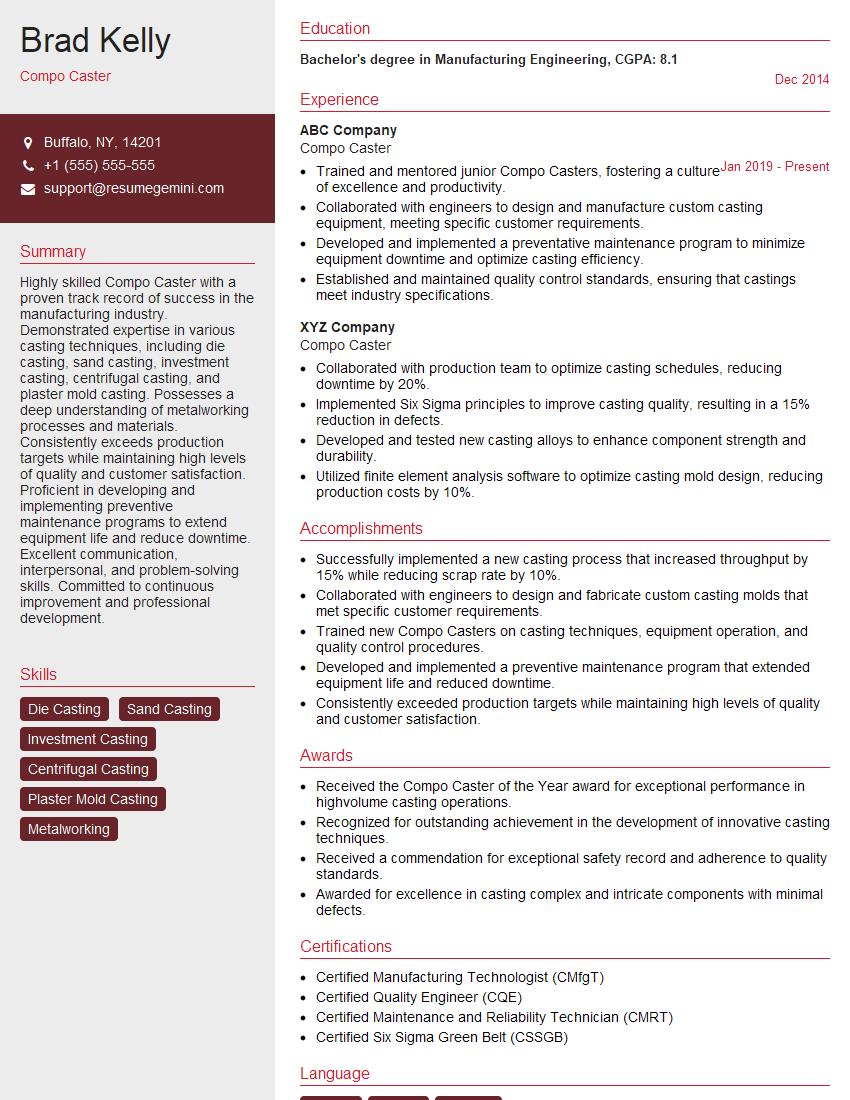

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compo Caster

1. Explain the process of continuous casting?

Continuous casting is a metalworking process in which molten metal is poured into a mold, which continuously solidifies into a billet, bloom, or slab. The process is used to produce a wide variety of metal products, including steel, aluminum, and copper. The continuous casting process consists of the following steps:

- The molten metal is poured into a tundish, which is a refractory-lined vessel that holds the molten metal and feeds it into the mold.

- The molten metal flows from the tundish into the mold, which is a water-cooled copper mold that shapes the metal into a billet, bloom, or slab.

- The metal solidifies as it passes through the mold and is then withdrawn from the mold by a series of pinch rolls.

- The billet, bloom, or slab is then cooled further and cut into the desired lengths.

2. What are the advantages of continuous casting over traditional casting methods?

Advantages of continuous casting:

- Higher productivity: Continuous casting is a much more efficient process than traditional casting methods, as it does not require the mold to be changed after each casting.

- Improved quality: Continuous casting produces a higher quality product than traditional casting methods, as the metal is not subjected to the same amount of heat and oxidation.

- Lower cost: Continuous casting is a more cost-effective process than traditional casting methods, as it requires less labor and energy.

3. What are the factors that affect the quality of the continuously cast product?

The quality of the continuously cast product is affected by a number of factors, including:

- The quality of the molten metal

- The design of the mold

- The casting speed

- The cooling rate

4. What are the different types of defects that can occur in continuously cast products?

The different types of defects that can occur in continuously cast products include:

- Surface defects, such as cracks, scabs, and slivers

- Internal defects, such as porosity, inclusions, and segregation

- Dimensional defects, such as out-of-roundness, ovality, and taper

5. What are the causes of these defects?

The causes of defects in continuously cast products can be attributed to a number of factors, including:

- Improper casting practices

- Inadequate mold design

- Variations in the quality of the molten metal

- Equipment malfunctions

6. What are the methods used to prevent these defects?

There are a number of methods that can be used to prevent defects in continuously cast products, including:

- Using high-quality molten metal

- Properly designing the mold

- Controlling the casting speed and cooling rate

- Regularly inspecting and maintaining the equipment

7. What are the different types of continuous casting machines?

There are two main types of continuous casting machines:

- Vertical continuous casting machines

- Horizontal continuous casting machines

8. What are the advantages and disadvantages of each type of machine?

Vertical continuous casting machines:

Advantages:

- Higher productivity

- Improved quality

- Lower cost

Disadvantages:

- More complex to operate

- Requires more maintenance

9. Horizontal continuous casting machines:

Advantages:

- Simpler to operate

- Requires less maintenance

Disadvantages:

- Lower productivity

- Reduced quality

- Higher cost

10. What are the latest developments in continuous casting technology?

The latest developments in continuous casting technology include:

- The use of new mold materials, such as graphite and ceramic

- The development of new casting processes, such as the electromagnetic casting process

- The use of computer-controlled systems to optimize the casting process

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compo Caster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compo Caster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Compo Casters are responsible for a range of tasks in the production of composite materials. Their primary duties include:

1. Cast and Mold Composite Materials

Compo Casters are responsible for casting and molding composite materials according to specifications. This process involves preparing the molds, mixing the composite materials, casting the materials into the molds, and curing the materials.

- Prepare and maintain molds and casting equipment, ensuring they are free of contaminants and defects.

- Mix and apply composite materials, following specified formulas and procedures.

2. Operate Casting Equipment

Compo Casters must be able to operate casting equipment, including furnaces, ovens, and curing chambers. They must also be able to monitor and control the temperature, pressure, and other conditions of the casting process.

- Control and monitor casting variables, such as temperature, pressure, and curing time.

- Maintain and calibrate casting equipment to ensure optimal performance and quality.

3. Inspect and Test Castings

Compo Casters are responsible for inspecting and testing castings to ensure that they meet quality standards. This may involve visual inspection, dimensional measurement, and mechanical testing.

- Inspect castings for defects, such as voids, cracks, and delaminations.

- Conduct physical and mechanical tests on castings to verify compliance with specifications.

4. Maintain Records and Reports

Compo Casters must maintain accurate records of all casting processes. This may include recording the materials used, the equipment operated, and the test results obtained.

- Maintain production logs and record process parameters for quality assurance purposes.

- Document any deviations or non-conformances encountered during the casting process.

Interview Tips

To ace an interview for a Compo Caster position, it is important to demonstrate your knowledge of the casting process and your ability to operate casting equipment. You should also be familiar with the industry standards for composite materials and be able to discuss your experience in this field.

1. Practice Your Answers

Take time to prepare for common interview questions. This will help you feel more confident and prepared during the interview.

- Research the company and the position.

- Prepare answers to questions about your experience, skills, and qualifications.

2. Highlight Your Experience

Be sure to highlight your relevant experience in your resume and cover letter. This will show the interviewer that you have the necessary skills and knowledge for the job.

- Quantify your accomplishments whenever possible.

- Use action verbs to describe your experience.

3. Be Enthusiastic

Show the interviewer that you are passionate about the casting process and eager to learn more. This will make you a more attractive candidate for the position.

- Be positive and enthusiastic throughout the interview.

- Ask thoughtful questions about the company and the position.

4. Dress Professionally

First impressions matter, so dress professionally for your interview. This will show the interviewer that you are serious about the position.

- Wear clean, pressed clothes.

- Choose conservative colors and styles.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Compo Caster interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.