Feeling lost in a sea of interview questions? Landed that dream interview for Composing Room Machinist but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Composing Room Machinist interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

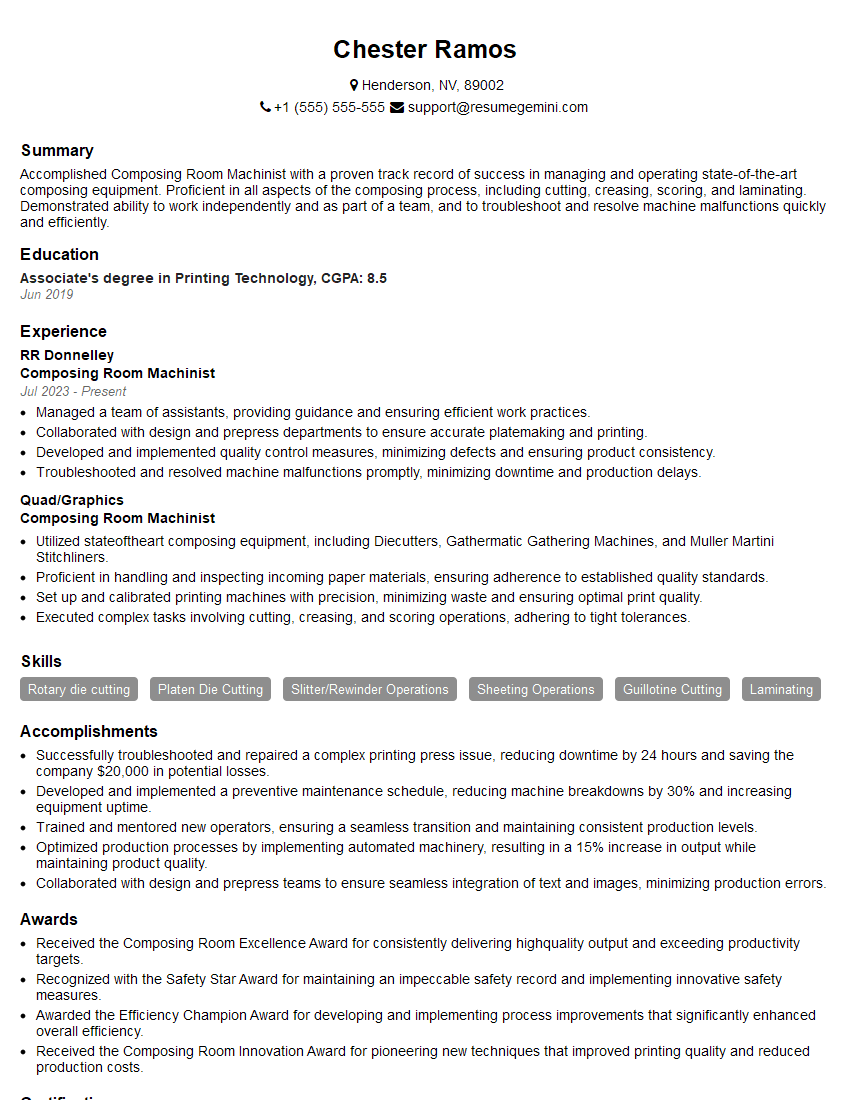

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Composing Room Machinist

1. How do you ensure that the printing plates are properly mounted on the press?

To ensure proper mounting, I follow a systematic process:

- Verify the alignment marks on the plate and the press cylinder.

- Use a precision measuring device to check the plate measurements against the press specifications.

- Clean the plate surface and the cylinder to remove any debris.

- Apply a release agent to the cylinder and carefully position the plate.

- Use a vacuum blanket to secure the plate onto the cylinder.

- Inspect the mounted plate for any misalignment or distortion.

2. Describe the process of setting up a web-fed printing press.

Web Tension Control

- Adjust the tension rollers to maintain the desired web tension.

- Monitor tension sensors to prevent web breaks or misregistration.

Ink and Water Balance

- Set the ink fountain keys to achieve the desired ink density.

- Adjust the water rollers to control ink emulsification and prevent smudging.

Printing Units

- Align the printing plates precisely on the impression cylinders.

- Check the impression pressure to ensure proper ink transfer.

Drying and Finishing

- Monitor the drying system to ensure proper ink curing.

- Adjust the folding and cutting units for accurate product handling.

3. What are the potential hazards associated with operating a printing press, and how do you mitigate them?

- Pinch Points: Maintain proper lockout/tagout procedures, wear protective gloves, and use machinery guards.

- Heavy Lifting: Use lifting equipment, practice proper lifting techniques, and seek assistance when necessary.

- Chemical Exposure: Wear appropriate PPE (masks, gloves, aprons), follow proper handling procedures, and ensure adequate ventilation.

- Machine Malfunctions: Implement regular maintenance, inspect equipment thoroughly, and shut down the press immediately if any issues arise.

- Electrical Hazards: Ensure proper grounding, use lockout/tagout procedures, and have an electrical safety program in place.

4. Explain the critical maintenance tasks for a printing press, and how often they should be performed.

- Daily Maintenance:

- Clean the printing plates and impression cylinders.

- Inspect the ink and water rollers for wear or damage.

- Check the web tension and alignment.

- Weekly Maintenance:

- Lubricate moving parts.

- Inspect the drive mechanisms for any signs of wear or damage.

- Clean the ink tanks and filters.

- Monthly Maintenance:

- Perform a thorough inspection of the entire press.

- Tighten all bolts and screws.

- Replace any worn or damaged components.

5. What is your experience with troubleshooting and repairing printing press malfunctions?

- Paper Jamming: Clear the jam, inspect the paper path for obstructions, and adjust roller pressure or web tension.

- Improper Ink Transfer: Check the ink density, water balance, and impression cylinder pressure.

- Misregistration: Verify plate alignment, roller settings, and the accuracy of the paper feed system.

- Electrical Faults: Use a multimeter to test electrical circuits, identify faulty components, and repair or replace them.

- Mechanical Breakdowns: Inspect gearboxes, bearings, and drive mechanisms for wear or damage.

6. Describe the quality control procedures you follow to ensure the accuracy of printed products.

- Pre-Press: Proofread copy, check colors and images for accuracy, and verify plate alignment.

- During Production: Monitor ink density, print quality, and paper registration.

- Post-Press: Inspect the finished products for defects, such as smudging, misfolding, or cutting inaccuracies.

- Customer Feedback: Obtain feedback from clients to identify potential quality issues and make improvements.

7. How do you stay up-to-date on the latest printing technologies and industry best practices?

- Attend industry conferences and workshops.

- Subscribe to trade publications and online forums.

- Participate in online training programs.

- Network with other printing professionals.

8. Describe a time when you had to work effectively as part of a team in a printing environment.

- Project: Production of a high-volume catalog.

- Role: Collaborated with prepress, press, and bindery teams.

- Communication: Regular updates on progress, challenges, and solutions.

- Flexibility: Adapted to changing deadlines and production requirements.

- Result: Successful completion of the project on time and within budget.

9. What do you consider to be your strengths and weaknesses as a Composing Room Machinist?

Strengths:

- Precision and attention to detail.

- Knowledge of printing press machinery and processes.

- Troubleshooting and repair skills.

- Strong work ethic and commitment to quality.

Weaknesses:

- Limited experience with some specialized printing equipment.

- Working in noisy and fast-paced environments can sometimes be challenging.

10. Why are you interested in working for our company?

- Reputation: Recognized industry leader with a proven track record of quality.

- Technology: State-of-the-art equipment and printing technologies.

- Team: Experienced and professional team that values collaboration.

- Growth Opportunities: Potential for professional development and career advancement.

- Culture: Commitment to excellence and a positive work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Composing Room Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Composing Room Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Composing Room Machinist is responsible for the operation and maintenance of composing room machinery, including assembling, adjusting, and repairing machines used in the production of printed materials.

1. Machine Operation

Operate and maintain composing room machinery, such as typesetting machines, phototypesetting machines, and platemaking equipment.

- Set up and adjust machinery according to specifications.

- Monitor machinery during operation and make necessary adjustments to ensure proper functioning.

2. Machine Maintenance

Perform routine maintenance and repairs on composing room machinery.

- Inspect machinery for wear and tear, and make necessary repairs.

- Lubricate and clean machinery to ensure smooth operation.

3. Troubleshooting

Troubleshoot and resolve problems with composing room machinery.

- Identify and diagnose problems with machinery.

- Make necessary repairs or adjustments to resolve problems.

4. Safety

Maintain a safe work environment in the composing room.

- Follow all safety procedures and regulations.

- Use proper safety equipment, such as gloves and safety glasses.

Interview Tips

In order to ace your interview for the Composing Room Machinist position, it is important to be well-prepared. Here are some tips to help you succeed:

1. Research the Company

Before your interview, take some time to research the company you are applying to. This will help you understand their business, culture, and values.

- Visit the company’s website and social media pages.

- Read articles about the company in industry publications.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance.

- Use the STAR method to answer interview questions.

- STAR stands for Situation, Task, Action, Result.

3. Prepare for Technical Questions

You will likely be asked some technical questions during your interview. These questions may be about your experience with composing room machinery or your knowledge of printing processes.

- Review your resume and be prepared to discuss your experience and skills.

- If you have any specific knowledge of composing room machinery or printing processes, be sure to highlight it in your interview.

4. Be Enthusiastic and Professional

It is important to be enthusiastic and professional during your interview. This will show the interviewer that you are interested in the position and that you are taking the interview seriously.

- Dress appropriately for the interview.

- Be on time for your interview.

- Make eye contact with the interviewer and speak clearly.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Composing Room Machinist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Composing Room Machinist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.