Feeling lost in a sea of interview questions? Landed that dream interview for Composite Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Composite Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

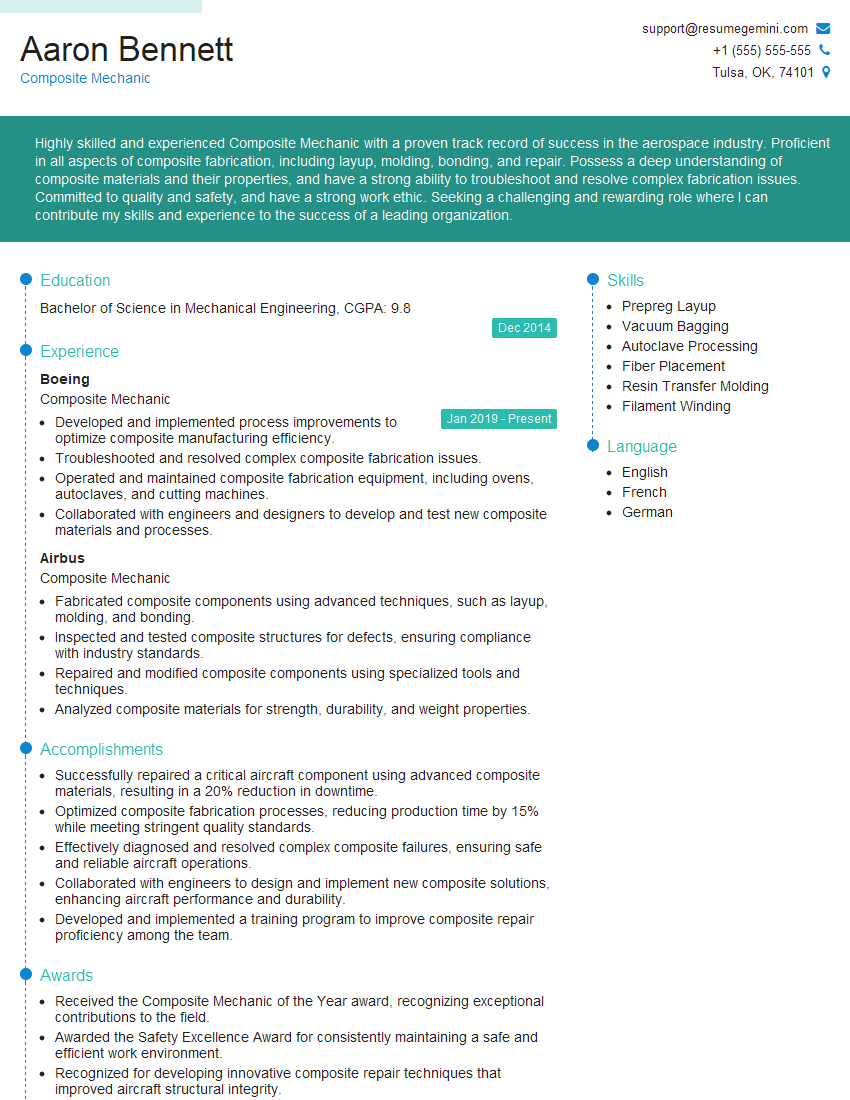

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Composite Mechanic

1. What are the different types of composite materials and their properties?

Composite materials are made of two or more different materials with different properties. The most common types of composite materials are:

- Fiber-reinforced composites: These composites are made of a reinforcing fiber (such as carbon fiber or glass fiber) embedded in a matrix material (such as epoxy or polyester). Fiber-reinforced composites are strong and lightweight, and they are often used in aerospace applications.

- Particulate composites: These composites are made of a reinforcing particles (such as metal or ceramic particles) embedded in a matrix material (such as epoxy or polyester). Particulate composites are strong and stiff, and they are often used in automotive applications.

- Laminated composites: These composites are made of layers of different materials bonded together. Laminated composites can be tailored to have specific properties, and they are often used in marine applications.

2. What are the different processes used to manufacture composite materials?

Lay-up process

- The lay-up process is the most common method of manufacturing composite materials. In this process, the reinforcing fibers are placed in a mold, and the matrix material is poured over the fibers. The mold is then heated and pressurized to cure the composite material.

Pultrusion process

- The pultrusion process is used to manufacture continuous-fiber composites. In this process, the reinforcing fibers are pulled through a resin bath and then through a heated die. The die shapes the composite material and cures it.

Molding process

- The molding process is used to manufacture complex-shaped composite materials. In this process, the reinforcing fibers are placed in a mold, and the matrix material is injected into the mold. The mold is then heated and pressurized to cure the composite material.

3. What are the different types of defects that can occur in composite materials?

The most common types of defects that can occur in composite materials are:

- Voids: Voids are air pockets that can occur in the composite material. Voids can weaken the composite material and make it more susceptible to damage.

- Delaminations: Delaminations are separations between the layers of a composite material. Delaminations can weaken the composite material and make it more susceptible to damage.

- Fiber breaks: Fiber breaks are breaks in the reinforcing fibers. Fiber breaks can weaken the composite material and make it more susceptible to damage.

- Matrix cracks: Matrix cracks are cracks in the matrix material. Matrix cracks can weaken the composite material and make it more susceptible to damage.

4. What are the different methods used to inspect composite materials?

The most common methods used to inspect composite materials are:

- Visual inspection: Visual inspection is the most basic method of inspecting composite materials. In this method, the composite material is visually inspected for any defects.

- Ultrasonic inspection: Ultrasonic inspection uses sound waves to detect defects in composite materials. In this method, sound waves are passed through the composite material, and the sound waves are reflected by any defects.

- Radiographic inspection: Radiographic inspection uses X-rays to detect defects in composite materials. In this method, X-rays are passed through the composite material, and the X-rays are absorbed by any defects.

- Computed tomography (CT) scan: A CT scan is a type of X-ray scan that can create three-dimensional images of composite materials. CT scans can be used to detect defects that are not visible on other types of inspections.

5. What are the different types of repairs that can be performed on composite materials?

The most common types of repairs that can be performed on composite materials are:

- Patch repair: A patch repair is a repair in which a new piece of composite material is bonded to the damaged area. Patch repairs are typically used to repair small defects.

- Scarf repair: A scarf repair is a repair in which the damaged area is removed and a new piece of composite material is bonded in its place. Scarf repairs are typically used to repair larger defects.

- In-situ repair: An in-situ repair is a repair in which the damaged area is repaired without removing the composite material from its original location. In-situ repairs are typically used to repair defects that are located in inaccessible areas.

6. What are the different types of tools and equipment used to work with composite materials?

The most common types of tools and equipment used to work with composite materials are:

- Scissors: Scissors are used to cut composite materials.

- Knives: Knives are used to trim and shape composite materials.

- Sanders: Sanders are used to smooth and finish composite materials.

- Drills: Drills are used to make holes in composite materials.

- Riveters: Riveters are used to install rivets in composite materials.

- Bonding tools: Bonding tools are used to bond composite materials together.

7. What are the safety precautions that must be taken when working with composite materials?

The most important safety precautions that must be taken when working with composite materials are:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator.

- Work in a well-ventilated area.

- Do not smoke or eat in the work area.

- Keep away from open flames.

- Dispose of composite materials properly.

8. What are the career opportunities for composite mechanics?

Composite mechanics can work in a variety of industries, including aerospace, automotive, marine, and construction. They can work as composite materials engineers, composite materials technicians, or composite materials inspectors.

The median annual salary for composite mechanics is $56,300. The top 10% of earners make more than $85,000 per year.

The demand for composite mechanics is expected to grow in the coming years as the use of composite materials continues to increase.

9. What are the qualities of a successful composite mechanic?

The most important qualities of a successful composite mechanic are:

- Strong technical skills

- Attention to detail

- Ability to work independently and as part of a team

- Good communication skills

- Problem-solving skills

- Willingness to learn new things

10. Why are you interested in working as a composite mechanic?

I am interested in working as a composite mechanic because I am fascinated by the properties of composite materials and their potential applications. I am also drawn to the challenge of working with these materials and the opportunity to make a difference in the world. I believe that my skills and experience would make me a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Composite Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Composite Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Composite Mechanics are responsible for the fabrication, repair, and maintenance of composite structures and components. They use a variety of materials and techniques to create lightweight and durable structures, including carbon fiber, fiberglass, and Kevlar.

1. Fabricate composite structures and components

Composite Mechanics follow blueprints and specifications to create composite structures and components. They use a variety of materials and techniques, including hand lay-up, vacuum bagging, and autoclave molding.

- Cut and shape composite materials.

- Lay up composite materials in molds.

- Cure composite materials using heat and pressure.

2. Repair composite structures and components

Composite Mechanics repair damaged composite structures and components. They use a variety of techniques, including patching, bonding, and resurfacing.

- Inspect composite structures and components for damage.

- Repair damaged composite structures and components using a variety of techniques.

- Test repaired composite structures and components to ensure they meet specifications.

3. Maintain composite structures and components

Composite Mechanics maintain composite structures and components to prevent damage and ensure they perform as intended. They perform a variety of tasks, including cleaning, inspecting, and testing.

- Clean composite structures and components.

- Inspect composite structures and components for damage.

- Test composite structures and components to ensure they meet specifications.

4. Work with other trades

Composite Mechanics often work with other trades, such as electricians, plumbers, and carpenters. They collaborate to ensure that composite structures and components are properly installed and maintained.

- Coordinate with other trades to ensure that composite structures and components are properly installed and maintained.

- Provide technical assistance to other trades on the use and maintenance of composite materials.

- Train other trades on the use and maintenance of composite materials.

Interview Tips

Preparing for an interview can be daunting, but there are things you can do to increase your chances of success. Here are a few tips to help you ace your Composite Mechanic interview:

1. Research the company and the position

Before you go on an interview, it’s important to research the company and the position you’re applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read the job description carefully to understand the specific requirements of the position.

- Check out the company’s social media pages to get a sense of their culture and values.

- Read reviews of the company on Glassdoor to get insights into the work environment and management style.

2. Practice answering common interview questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Prepare an elevator pitch that summarizes your skills and experience.

- Practice answering questions about your experience with composite materials and fabrication techniques.

- Be prepared to discuss your knowledge of the industry and the latest trends in composite materials.

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This shows that you’re respectful of the interviewer’s time and that you’re eager to make a good impression.

- Wear clean, pressed clothes that are appropriate for a business setting.

- Arrive at the interview location on time, or even a few minutes early.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic about the position and the company. They want to know that you’re passionate about your work and that you’re excited about the opportunity to join their team. Be sure to show your enthusiasm and positivity throughout the interview.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Be positive and enthusiastic about the position and the company.

5. Ask questions

Asking questions at the end of the interview shows that you’re interested in the position and the company. It also gives you an opportunity to learn more about the company and the culture. Be sure to ask thoughtful questions that are relevant to the position and the company.

- Ask about the company’s culture and values.

- Ask about the company’s plans for the future.

- Ask about the specific responsibilities of the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Composite Mechanic role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.