Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Composite Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Composite Technician so you can tailor your answers to impress potential employers.

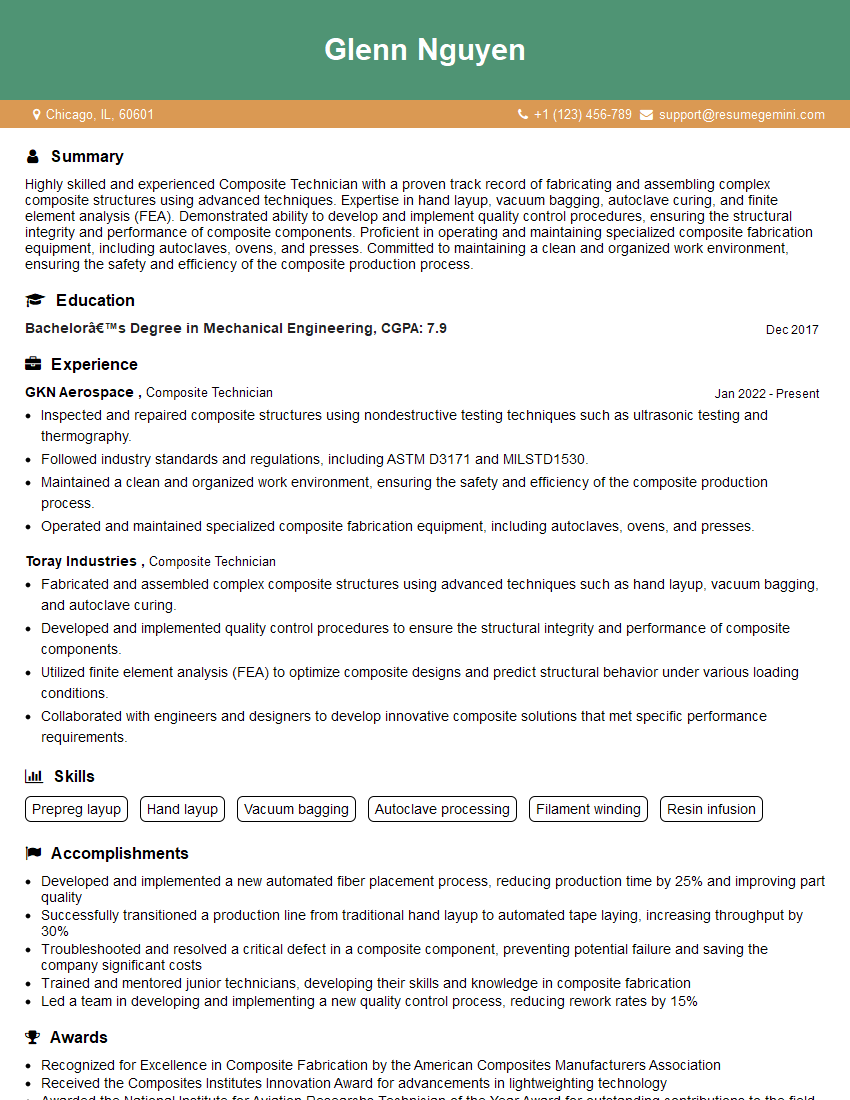

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Composite Technician

1. Describe the process of laying up composite materials.

- Prepare the mold surface by cleaning and applying release agent.

- Cut and lay up the composite materials in the mold, following the design specifications.

- Compact the materials using a vacuum bag or press to remove air and ensure proper bonding.

- Cure the composite materials according to the manufacturer’s instructions.

- Remove the cured composite part from the mold and inspect it for quality.

2. What are the different types of composite materials?

Thermoplastics

- Can be melted and remolded multiple times

- Examples: polyethylene, polypropylene

Thermosets

- Cure permanently and cannot be remolded

- Examples: epoxy, polyester

Metal-matrix composites

- Combine a metal matrix with a ceramic or organic fiber reinforcement

- Examples: aluminum-silicon carbide, titanium-boron

3. What are the advantages and disadvantages of using composite materials?

Advantages

- Lightweight and high strength

- Resistant to corrosion and chemicals

- Can be molded into complex shapes

Disadvantages

- Can be expensive to manufacture

- Susceptible to damage from impact

- Can be difficult to repair

4. What are the different methods of curing composite materials?

Autoclave curing

- Uses pressure and heat to cure the materials

- Produces high-quality parts with minimal voids

Oven curing

- Uses heat to cure the materials

- Less expensive than autoclave curing

Room temperature curing

- Uses ambient temperature to cure the materials

- Slowest curing method

5. What are the different types of reinforcements used in composite materials?

Fibers

- Glass fibers

- Carbon fibers

- Aramid fibers

Particles

- Ceramic particles

- Metal particles

Hybrids

- Combinations of different types of reinforcements

6. What are the different test methods used to evaluate the properties of composite materials?

Mechanical testing

- Tensile testing

- Compressive testing

- Shear testing

Non-destructive testing

- Ultrasonic testing

- Radiography

- Thermography

7. What is the difference between a composite laminate and a composite sandwich structure?

Composite laminate

- Consists of multiple layers of composite material

- Laminated together to achieve specific properties

Composite sandwich structure

- Consists of two face sheets of composite material

- Separated by a core material, such as honeycomb or foam

- Lightweight and stiff

8. What are the challenges of working with composite materials?

Safety

- Composite materials can contain hazardous chemicals

- Proper safety precautions must be taken

Environmental impact

- Composite materials can be difficult to dispose of

- Eco-friendly disposal methods must be considered

Cost

- Composite materials can be expensive

- Cost must be balanced against performance benefits

9. What are the emerging trends in composite materials?

Nanotechnology

- Incorporation of nanoparticles into composite materials

- Enhanced properties, such as strength and toughness

Biocomposites

- Use of natural fibers, such as flax and bamboo

- Lightweight and sustainable

Additive manufacturing

- Use of 3D printing to create complex composite structures

- Reduced waste and faster production time

10. How do you stay up-to-date with the latest developments in composite materials?

Attend conferences and workshops

- Network with other professionals

- Learn about new technologies and applications

Read technical journals and articles

- Keep abreast of the latest research and developments

- Enhance knowledge and skills

Take online courses and certifications

- Formalize knowledge and demonstrate expertise

- Advance career opportunities

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Composite Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Composite Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Composite Technicians play a pivotal role in the fabrication, repair, and maintenance of composite materials used across various industries. These highly skilled professionals possess a comprehensive understanding of composite materials, their properties, and manufacturing processes. Their core responsibilities include:

1. Composite Fabrication

Prepare and modify composite materials according to engineering specifications.

- Select and cut materials, such as carbon fiber, fiberglass, and epoxy resins.

- Laminate and cure composite components using techniques like hand lay-up, vacuum infusion, and autoclave molding.

2. Quality Control and Inspection

Ensure the quality and integrity of composite structures through rigorous inspections.

- Perform non-destructive testing (NDT) techniques like ultrasonic and radiographic inspections.

- Interpret test results and identify potential defects or deviations from specifications.

3. Repair and Maintenance

Diagnose and repair damaged composite components, restoring their functionality and structural integrity.

- Inspect composite structures for cracks, delamination, and other damage.

- Develop and implement repair plans using appropriate materials and techniques.

4. Production and Assembly

Assemble and integrate composite components into larger structures and systems.

- Use specialized tools and equipment to join composite parts, including adhesives, mechanical fasteners, and welding.

- Work in collaboration with engineers and other professionals to ensure proper fit and functionality.

Interview Tips

Preparing for a Composite Technician interview requires a combination of technical knowledge and effective communication skills. Here are some tips to help you stand out:

1. Research the Company and Role

Thoroughly research the company’s history, products, and industry to demonstrate your interest and understanding of their business. Study the job description carefully to identify the key skills and responsibilities required for the role.

2. Highlight Your Technical Expertise

Showcase your proficiency in composite materials, fabrication techniques, and quality control procedures. Describe your experience with different types of composite materials, molding processes, and NDT techniques. Quantify your accomplishments with specific examples that demonstrate your technical abilities.

3. Emphasize Your Problem-Solving Skills

Composite Technicians often encounter challenges in their work. Emphasize your ability to diagnose and solve problems effectively. Provide examples of situations where you used critical thinking, analytical skills, and practical knowledge to resolve technical issues.

4. Demonstrate Your Attention to Detail

In this field, precision and attention to detail are essential. Highlight your meticulous nature and your commitment to quality craftsmanship. Describe your processes for ensuring accuracy in your work, including your experience with inspection techniques and quality control standards.

5. Communication and Teamwork Skills

Collaboration and effective communication are essential for Composite Technicians. Describe your experience working in a team environment, exchanging information with engineers, and communicating technical concepts clearly. Showcase your proficiency in technical writing and your ability to document your work effectively.

Next Step:

Now that you’re armed with the knowledge of Composite Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Composite Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini