Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Composition Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

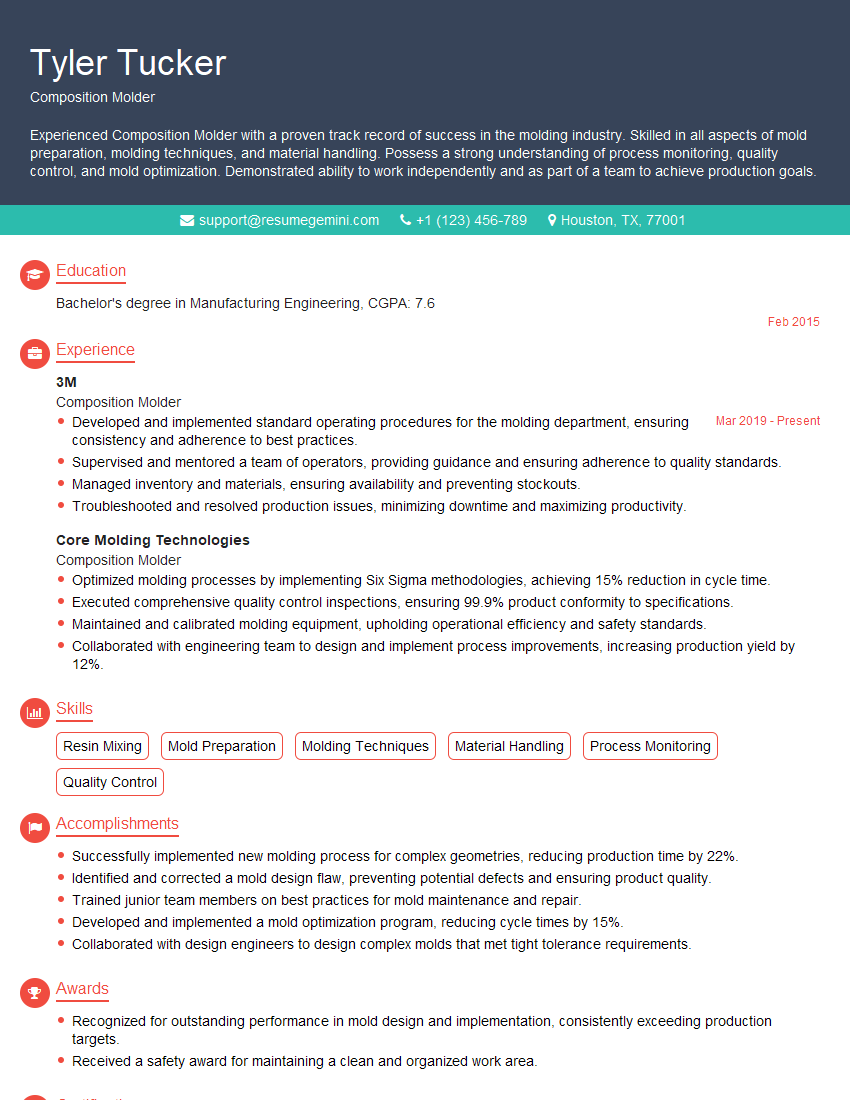

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Composition Molder

1. Describe the process of preparing a mold for composition molding.

The process of preparing a mold for composition molding involves several key steps:

- Surface preparation: The mold surface is cleaned and polished to remove any contaminants and ensure a smooth finish.

- Mold release application: A mold release agent is applied to the mold surface to prevent the molded part from sticking to the mold.

- Component mixing: The composition material, typically a mixture of resin, filler, and other additives, is mixed according to the manufacturer’s specifications.

- Mold filling: The mixed composition is poured or injected into the mold cavity, filling it completely.

- Curing: The filled mold is heated or exposed to a curing agent to harden the composition material.

- Demolding: Once cured, the molded part is removed from the mold.

2. How do you ensure the accuracy and precision of molded parts?

Dimensional control

- Use precision molds with accurate dimensions.

- Control the process parameters, such as curing time and temperature, to minimize dimensional variations.

Surface quality

- Use high-quality mold materials and finishes to achieve a smooth and blemish-free surface.

- Optimize the mold release process to prevent surface defects.

3. What factors affect the strength and durability of molded parts?

- Material selection: The composition material’s properties, such as strength, hardness, and chemical resistance, play a significant role.

- Mold design: Proper mold design ensures even distribution of material and eliminates stress concentrations.

- Process parameters: Curing conditions, such as temperature and time, affect the material’s cross-linking and strength.

- Post-molding processes: Heat treatment or other post-processing techniques can further enhance the strength and durability of molded parts.

4. What are the common defects in composition molding and how do you prevent them?

- Voids and porosity: Ensure proper mold filling and use vacuum degassing to remove trapped air.

- Dimensional inaccuracy: Use precision molds and control process parameters to maintain dimensional tolerances.

- Surface defects: Optimize mold release and use proper mold maintenance techniques to prevent surface imperfections.

- Cracking and delamination: Control curing conditions to avoid thermal stress and ensure proper adhesion between layers.

- Flash: Use well-fitting molds and adjust injection parameters to prevent excess material from escaping the mold.

5. How do you handle hazardous materials used in composition molding?

- Follow established safety protocols for handling hazardous materials.

- Use appropriate personal protective equipment (PPE) such as gloves, masks, and protective clothing.

- Maintain a well-ventilated work area and use fume hoods or exhaust systems to remove hazardous vapors.

- Dispose of waste materials properly according to environmental regulations.

6. Describe the different types of composition molding presses.

- Hand-operated presses: Used for small-scale production or prototyping.

- Hydraulic presses: Provide high pressure and precision for molding larger parts.

- Automatic presses: Offer automation and high production rates for mass production.

7. What are the advantages and disadvantages of using composition molding compared to other molding techniques?

Advantages

- High dimensional accuracy and detail reproduction.

- Ability to produce complex shapes and geometries.

- Strength and durability of molded parts.

Disadvantages

- Relatively slow production rates compared to injection molding.

- Higher tooling costs for custom molds.

- Potential for hazardous materials handling.

8. What is the role of mold maintenance in composition molding?

- Prevent defects: Regular mold maintenance helps identify and fix potential issues that could lead to defective parts.

- Extend mold life: Proper maintenance extends the operational life of molds, reducing downtime and replacement costs.

- Improve productivity: Well-maintained molds result in smoother production processes and improved productivity.

9. Describe the quality control measures used in composition molding.

- Dimensional inspection: Use measuring tools to verify part accuracy against specifications.

- Visual inspection: Examine parts for defects, such as cracks, voids, or surface imperfections.

- Mechanical testing: Conduct tests to assess the strength, durability, and performance of molded parts.

10. What are the emerging trends and advancements in composition molding?

- Advanced materials: Development of new composition materials with improved properties and performance.

- Automation and robotics: Integration of automated systems to increase production efficiency.

- Digital molding: Use of 3D printing and additive manufacturing techniques to create molds.

- Sustainable practices: Focus on reducing environmental impact through the use of eco-friendly materials and processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Composition Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Composition Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The primary responsibilities of a Composition Molder revolve around the operation and maintenance of machines used to produce molded parts from composite materials.

1. Machine Operation and Monitoring

A Composition Molder is entrusted with the task of setting up, operating and monitoring molding machines, ensuring that they run smoothly and produce molds with optimal quality.

- Set up and calibrate molding machines according to specifications.

- Monitor machine performance and make adjustments as needed.

2. Mold Preparation and Maintenance

In order to create high-quality molded parts, mold preparation and maintenance plays a crucial role, and it is a key aspect of a Composition Molder’s job.

- Prepare and maintain molds by cleaning, lubricating, and repairing them.

- Inspect molds for defects and wear, and report any issues to supervisors.

3. Material Handling and Storage

Proper material handling and storage are essential for the efficient operation of molding processes.

- Handle and store raw materials and finished products safely and efficiently.

- Maintain inventory of materials and ensure adequate supply.

4. Quality Control and Inspection

The quality of molded parts is of paramount importance, and Composition Molders play a vital role in ensuring that.

- Inspect molded parts for defects and ensure they meet specifications.

- Report any quality issues to supervisors and assist in corrective actions.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of making a positive impression and landing the job.

1. Research the Company and the Role

Take the time to learn about the company’s history, culture, products or services, and the specific responsibilities of the Composition Molder role.

- Visit the company’s website.

- Read industry news and articles.

2. Practice Answering Common Interview Questions

There are several common interview questions that you are likely to encounter, so it’s helpful to prepare your answers in advance.

- Tell me about yourself.

- Why are you interested in this role?

3. Highlight Your Skills and Experience

Make sure to highlight the skills and experience that are most relevant to the job. Use specific examples to demonstrate your abilities.

- Describe your experience operating and monitoring molding machines.

- Provide examples of your quality control and inspection procedures.

4. Be Enthusiastic and Confident

A positive attitude and a belief in your abilities will go a long way in making a good impression on the interviewer.

- Smile and make eye contact.

- Speak clearly and confidently.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Composition Molder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.