Are you gearing up for an interview for a Compounding and Finishing Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Compounding and Finishing Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

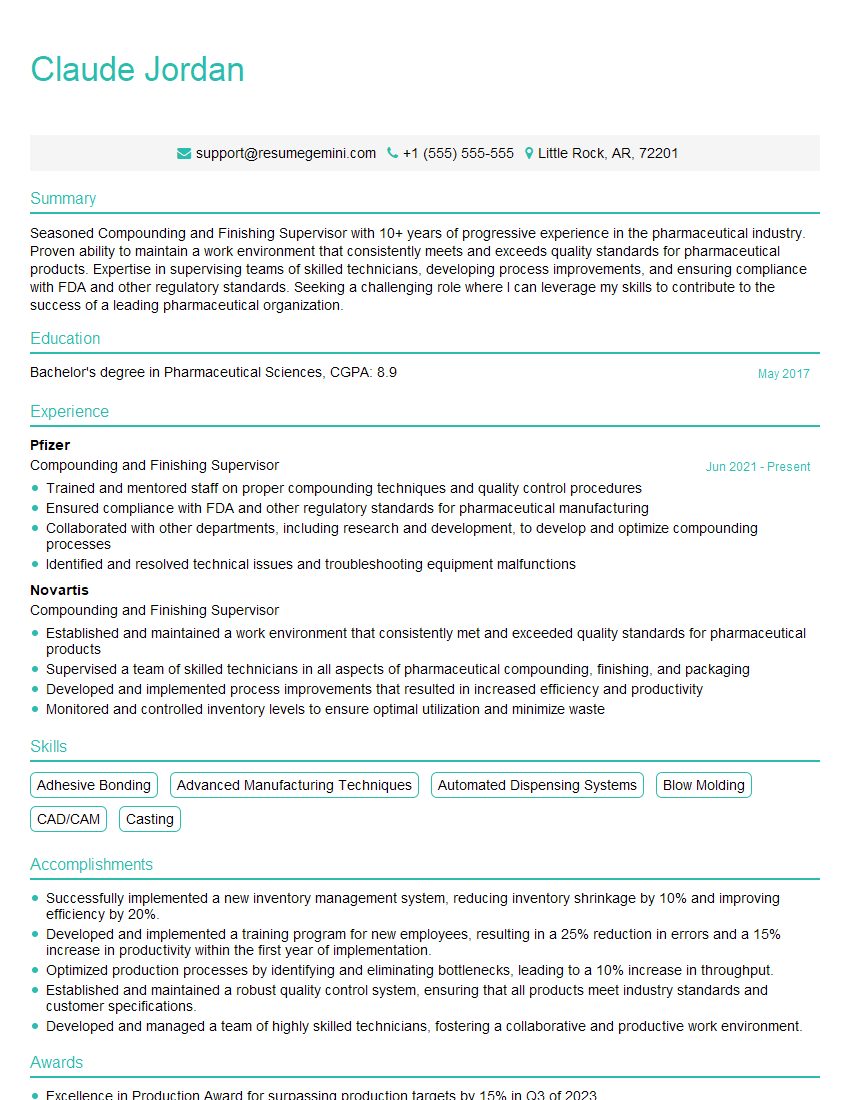

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compounding and Finishing Supervisor

1. How would you optimize the efficiency of the compounding process to minimize waste and increase productivity?

To optimize the compounding process and minimize waste, I would:

- Analyze current processes to identify inefficiencies and areas for improvement.

- Implement lean manufacturing principles to reduce waste, such as using standardized work instructions and implementing a continuous improvement program.

- Utilize technology, such as automated dispensing systems, to increase accuracy and reduce material usage.

- Train operators on proper mixing techniques and equipment maintenance to ensure optimal performance.

- Establish a system for monitoring and controlling process parameters to minimize variability and ensure consistent quality.

2. Discuss the importance of quality control in the finishing process and outline the steps you would take to ensure product quality.

Quality Control in Finishing

- Ensures product meets specifications and customer requirements.

- Prevents defects and rework, reducing costs.

- Maintains brand reputation and customer satisfaction.

Steps to Ensure Product Quality

- Establish clear quality standards and inspection criteria.

- Train operators on proper inspection techniques and equipment.

- Implement a comprehensive quality control plan, including regular inspections, testing, and documentation.

- Use statistical process control (SPC) techniques to monitor and analyze process performance.

- Identify and address root causes of quality issues.

3. How do you manage a team of operators in a fast-paced production environment to ensure product quality and meet deadlines?

To manage a team effectively in a fast-paced production environment, I would:

- Establish clear expectations, goals, and performance standards.

- Provide clear and concise work instructions and training.

- Foster a culture of accountability and continuous improvement.

- Empower operators to make decisions and resolve issues.

- Implement a performance management system to track progress and identify areas for improvement.

- Provide regular feedback and recognition to motivate and engage the team.

4. Describe your experience in troubleshooting and resolving complex technical issues in a compounding and finishing operation.

In my previous role as Compounding and Finishing Supervisor, I encountered a complex issue where the finished product was exhibiting surface defects. I conducted a thorough investigation, including:

- Examining the raw materials and equipment.

- Analyzing process parameters and equipment settings.

- Consulting with technical experts and suppliers.

- Implementing test batches with varying parameters.

Through this process, I identified that the issue was caused by a specific impurity in the raw material. I worked with the supplier to address the issue, and implemented a new quality control procedure to prevent future occurrences.

5. How do you stay up-to-date with industry best practices and technological advancements in compounding and finishing?

To stay current with industry best practices and technological advancements, I engage in continuous learning:

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Network with professionals in the field.

- Participate in online forums and discussion groups.

- Research and evaluate new technologies.

This ongoing learning allows me to stay abreast of the latest trends and innovations, and to implement them effectively in my work.

6. Explain the importance of effective communication and collaboration with other departments, such as production and quality control, in the compounding and finishing process.

Effective communication and collaboration are crucial for the smooth operation of the compounding and finishing process:

- Production: Coordination ensures timely delivery of raw materials and finished products.

- Quality Control: Collaboration ensures adherence to quality standards and timely resolution of quality issues.

I proactively engage with other departments to:

- Establish clear communication channels.

- Regularly update on process status and potential issues.

- Participate in cross-functional meetings.

- Share knowledge and expertise.

7. How do you ensure compliance with regulatory standards for compounding and finishing operations, such as ISO 9001?

Compliance with regulatory standards is paramount. To ensure compliance, I:

- Maintain up-to-date knowledge of applicable standards.

- Implement a quality management system based on the standards.

- Conduct regular internal audits to assess compliance.

- Train operators on the requirements of the standards.

- Document all processes and procedures related to compliance.

- Work closely with external auditors to ensure successful certification.

8. Describe your experience in managing inventory and materials in a compounding and finishing operation.

Effective inventory management is crucial for smooth operations. I have implemented the following strategies:

- Established a robust inventory control system.

- Optimized inventory levels to minimize waste and reduce costs.

- Implemented a first-in, first-out (FIFO) system for materials.

- Established clear procedures for material handling and storage.

- Regularly monitored inventory levels and adjusted orders accordingly.

These measures have significantly improved inventory accuracy and ensured the availability of materials for production.

9. How do you motivate and engage a team of operators in a demanding and fast-paced work environment?

Motivating and engaging employees is essential for productivity. I utilize the following strategies:

- Foster a positive and supportive work environment.

- Set clear goals and expectations.

- Provide regular feedback and recognition.

- Empower employees to make decisions and solve problems.

- Promote teamwork and collaboration.

- Offer opportunities for professional development and growth.

By creating a motivating work environment, I have consistently achieved high levels of employee engagement and productivity.

10. Describe your approach to continuous improvement and process optimization in the compounding and finishing process.

Continuous improvement is key to optimizing operations. My approach includes:

- Regularly reviewing processes to identify areas for improvement.

- Utilizing lean manufacturing principles and tools.

- Implementing new technologies and techniques.

- Encouraging employee input and suggestions.

- Measuring and tracking performance metrics.

- Making data-driven decisions to improve processes.

Through continuous improvement, I have successfully reduced waste, improved efficiency, and enhanced product quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compounding and Finishing Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compounding and Finishing Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Compounding and Finishing Supervisor is responsible for overseeing the day-to-day operations of the compounding and finishing department. This includes ensuring that all products are produced to the highest quality standards, that all safety protocols are followed, and that all production goals are met.

1. Product Quality Assurance

The Compounding and Finishing Supervisor is responsible for ensuring that all products meet the highest quality standards.

- Develop and implement quality control procedures.

- Inspect products throughout the production process to ensure that they meet specifications.

- Investigate and resolve any quality issues that arise.

2. Safety Management

The Compounding and Finishing Supervisor is responsible for ensuring that all safety protocols are followed.

- Develop and implement safety procedures.

- Train employees on safety procedures.

- Enforce safety regulations.

3. Production Management

The Compounding and Finishing Supervisor is responsible for ensuring that all production goals are met.

- Develop and implement production schedules.

- Monitor production progress.

- Identify and resolve any production issues that arise.

4. Team Management

The Compounding and Finishing Supervisor is responsible for leading and motivating a team of employees.

- Recruit, hire, and train employees.

- Provide performance feedback and coaching.

- Resolve employee conflicts.

Interview Tips

Preparing for an interview can be daunting, but there are some things you can do to increase your chances of success. Here are a few tips:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, and it will also help you tailor your answers to the interviewer’s questions.

2. Be Yourself

It is important to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you are not. Be honest and authentic, and let your personality shine through.

3. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

4. Be Prepared to Talk About Your Experience – STAR

When answering interview questions, use the STAR method to highlight your experience. STAR stands for Situation, Task, Action, and Result. When describing your experience, be sure to provide specific examples and quantify your results whenever possible.

5. Ask Questions

At the end of your interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the opportunity and that you are taking the interview seriously.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Compounding and Finishing Supervisor role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.