Feeling lost in a sea of interview questions? Landed that dream interview for Compressed Gas Equipment Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Compressed Gas Equipment Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

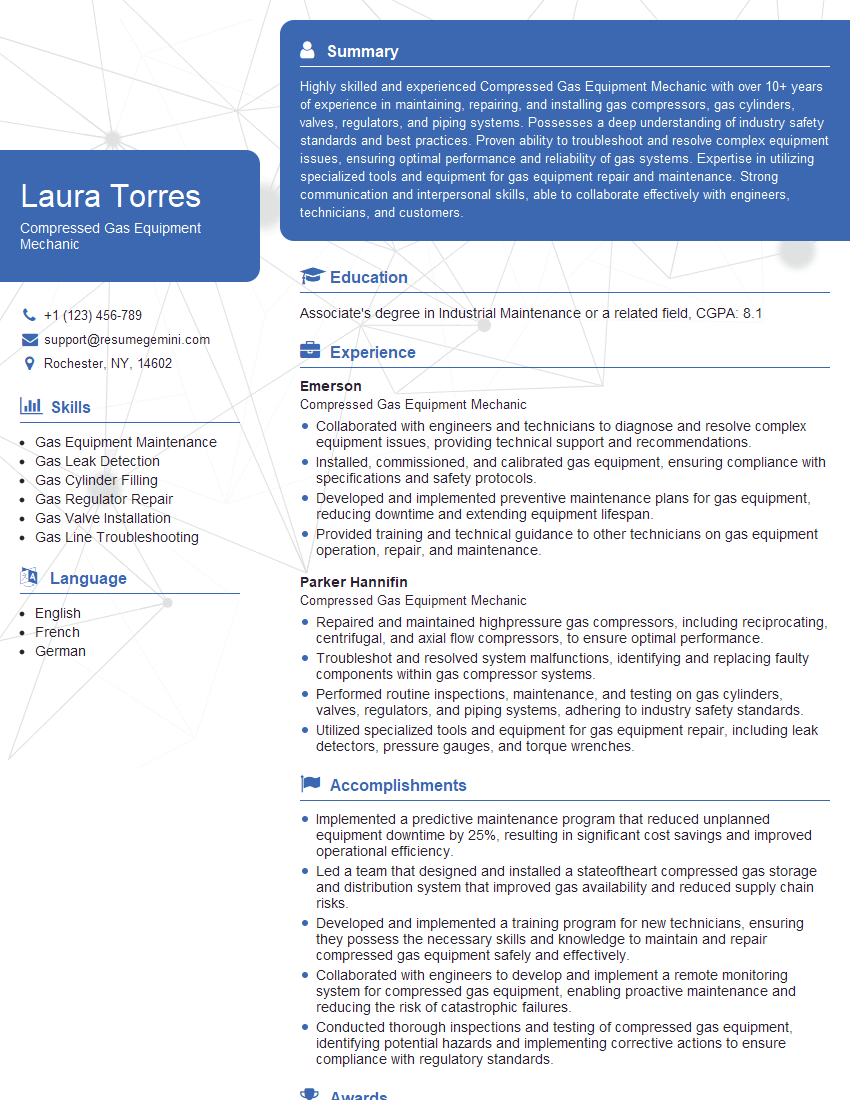

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compressed Gas Equipment Mechanic

1. Describe the steps involved in inspecting a compressed gas cylinder.

- Visually inspect the cylinder for any dents, cracks, or other damage.

- Check the cylinder’s pressure gauge to ensure that it is within the safe operating range.

- Check the cylinder’s valve for any leaks.

- Weigh the cylinder to ensure that it is not overfilled.

- Record the inspection results on a tag that is attached to the cylinder.

2. What are the different types of compressed gas cylinders?

Types of Compressed Gas Cylinders

- Steel cylinders: These are the most common type of compressed gas cylinder. They are made of high-strength steel and can withstand high pressures.

- Aluminum cylinders: These cylinders are lighter than steel cylinders and are often used for portable applications.

- Composite cylinders: These cylinders are made of a combination of materials, such as fiberglass and carbon fiber. They are lightweight and durable.

Materials of Construction

- Type 1: Seamless, steel

- Type 2: Seamless, aluminum

- Type 3: Welded, steel

- Type 4: Welded, aluminum

- Type 5: Composite

3. What are the safety precautions that must be taken when working with compressed gases?

- Always wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Never smoke or use open flames near compressed gases.

- Never attempt to repair or modify a compressed gas cylinder.

- Never store compressed gas cylinders in direct sunlight or near heat sources.

- Always secure compressed gas cylinders when transporting them.

- Always use the proper tools and equipment when working with compressed gases.

- Always follow the manufacturer’s instructions when using compressed gases.

4. What are the different types of valves used on compressed gas cylinders?

- Cylinder valves: These valves are located on the top of the cylinder and are used to control the flow of gas into and out of the cylinder.

- Regulator valves: These valves are located between the cylinder valve and the gas line and are used to reduce the pressure of the gas to a safe working level.

- Safety relief valves: These valves are located on the cylinder or regulator and are used to prevent the pressure in the cylinder or line from exceeding a safe level.

5. What are the different types of gas regulators?

- Single-stage regulators: These regulators reduce the pressure of the gas in one step.

- Two-stage regulators: These regulators reduce the pressure of the gas in two steps, which provides a more precise and stable output pressure.

- Diaphragm regulators: These regulators use a diaphragm to control the flow of gas.

- Piston regulators: These regulators use a piston to control the flow of gas.

6. What are the different types of gas fittings?

- Pipe fittings: These fittings are used to connect pipes and tubes.

- Hose fittings: These fittings are used to connect hoses to pipes and other fittings.

- Tube fittings: These fittings are used to connect tubes to each other and to other fittings.

7. What are the different types of gas leak detectors?

- Electronic leak detectors: These detectors use a sensor to detect the presence of gas.

- Ultrasonic leak detectors: These detectors use ultrasonic waves to detect the presence of gas.

- Bubble leak detectors: These detectors use a soap solution to detect the presence of gas.

8. What are the different types of compressed gas storage systems?

- High-pressure storage systems: These systems store gas at pressures of up to 3,000 psi.

- Low-pressure storage systems: These systems store gas at pressures of up to 500 psi.

- Ambient-temperature storage systems: These systems store gas at room temperature.

- Cryogenic storage systems: These systems store gas at very low temperatures (-200°F or lower).

9. What are the different types of compressed gas applications?

- Industrial applications: These applications include the use of compressed gases for welding, cutting, and other industrial processes.

- Medical applications: These applications include the use of compressed gases for anesthesia, surgery, and other medical procedures.

- Scientific applications: These applications include the use of compressed gases for research and development.

- Consumer applications: These applications include the use of compressed gases for home and personal use.

10. What are the different types of compressed gas safety regulations?

- OSHA regulations: These regulations are enforced by the Occupational Safety and Health Administration (OSHA) and apply to all workplaces in the United States.

- DOT regulations: These regulations are enforced by the Department of Transportation (DOT) and apply to the transportation of compressed gases.

- NFPA regulations: These regulations are published by the National Fire Protection Association (NFPA) and provide guidance on the safe handling and storage of compressed gases.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compressed Gas Equipment Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compressed Gas Equipment Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Compressed Gas Equipment Mechanics are responsible for installing, maintaining, and repairing compressed gas equipment, such as cylinders, tanks, and valves. They must be familiar with the principles of gas compression, as well as the specific requirements of the equipment they are working on. This role requires a strong understanding of safety procedures, as compressed gas can be dangerous if not handled properly.

1. Installation

Install new compressed gas equipment according to manufacturer’s specifications

- Secure equipment in place

- Connect equipment to gas supply

2. Maintenance

Inspect and test compressed gas equipment regularly

- Identify and repair any defects

- Lubricate and clean equipment

3. Repair

Diagnose and repair malfunctioning compressed gas equipment

- Replace parts as necessary

- Adjust equipment to ensure proper operation

4. Safety

Follow all safety procedures when working with compressed gas

- Wear appropriate personal protective equipment

- Inspect equipment for leaks regularly

- Handle compressed gas carefully

Interview Tips

1. Research the company and the position

– Visit the company’s website to learn about their history, culture, and values. – Read job descriptions carefully to understand the specific requirements of the position.2. Practice your answers to common interview questions

– Prepare for questions about your experience, skills, and qualifications. – Use the STAR method to answer questions (Situation, Task, Action, Result).3. Dress professionally and arrive on time

– First impressions matter, so dress appropriately for the interview. – Arrive on time to show that you are respectful of the interviewer’s time.4. Be prepared to ask questions

– Asking thoughtful questions shows that you are interested in the position and the company. – Prepare questions about the company, the position, and the interviewer’s experience.5. Follow up after the interview

– Send a thank-you note to the interviewer within 24 hours of the interview. – Reiterate your interest in the position and thank the interviewer for their time.Next Step:

Now that you’re armed with the knowledge of Compressed Gas Equipment Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Compressed Gas Equipment Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini