Feeling lost in a sea of interview questions? Landed that dream interview for Compressed Gas Equipment Service Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Compressed Gas Equipment Service Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

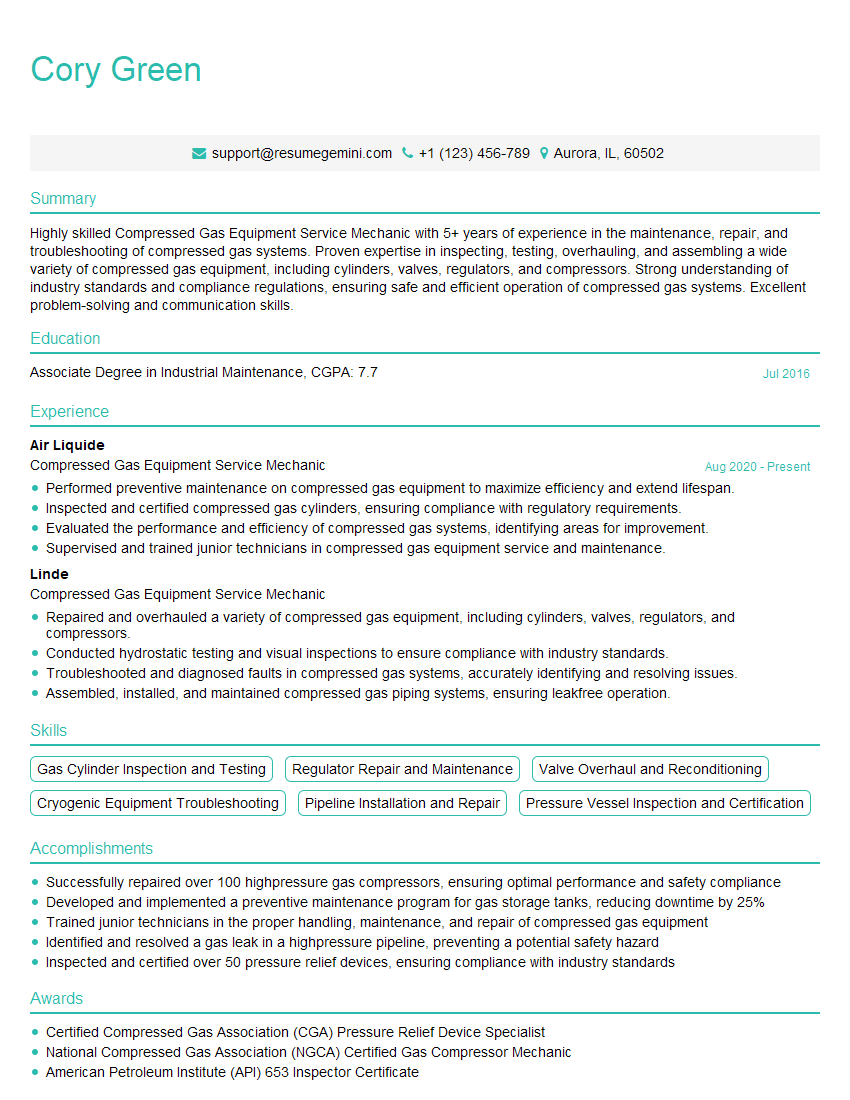

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compressed Gas Equipment Service Mechanic

1. How do you ensure the safe operation of compressed gas equipment?

- Performing regular inspections and maintenance to identify and correct any potential hazards.

- Following established safety protocols and procedures for handling, transporting, and storing compressed gases.

- Using appropriate personal protective equipment (PPE) and ensuring that it is properly fitted and maintained.

- Training staff on safety hazards and emergency procedures related to compressed gas equipment.

- Establishing a clear communication system to report and address any safety concerns.

2. What are the key steps involved in troubleshooting and repairing a compressed gas leak?

Identifying the Source

- Using leak detection equipment and visual inspection to locate the source of the leak.

- Checking connections, fittings, valves, and hoses for signs of damage or wear

Isolating the Leak

- Closing the isolation valve nearest to the leak to stop the flow of gas.

- Depressurizing the system by releasing the pressure through a controlled vent.

Fixing the Leak

- Replacing damaged or faulty components, such as gaskets, seals, valves, or hoses

- Tightening loose connections or fittings

Testing and Commissioning

- Conducting pressure tests to ensure the repair has been successful and there are no further leaks.

- Commissioning the system to restore it to normal operation.

3. What are the different types of compressed gas equipment you have experience servicing?

- Air compressors, including reciprocating, rotary screw, and centrifugal compressors

- Gas cylinders and tanks, as well as their valves and regulators

- Piping and tubing systems used to transport compressed gases

- Pressure vessels and receivers

- Control systems and instrumentation related to compressed gas equipment

4. What are the common safety hazards associated with compressed gas systems and how can they be mitigated?

- Pressure-related hazards: Explosions, ruptures, and uncontrolled releases of compressed gas. Mitigation: Proper design, construction, and maintenance of pressure vessels and piping systems; pressure relief devices; training and supervision.

- Toxicity hazards: Exposure to harmful or poisonous gases. Mitigation: Proper ventilation; respiratory protection; gas detection systems; emergency response plans.

- Fire hazards: Compressed gases can fuel or intensify fires. Mitigation: Proper storage and handling; fire protection systems; training and emergency procedures.

- Cryogenic hazards: Exposure to extremely low temperatures. Mitigation: Proper handling and storage of cryogenic gases; cryogenic protective equipment; training and supervision.

- Electrical hazards: Electrical equipment used with compressed gas systems can pose shock and arc-flash risks. Mitigation: Proper grounding; electrical safety inspections; qualified electricians.

5. Describe the process of inspecting and testing compressed gas cylinders for compliance with industry standards.

- Visual inspection: Checking for dents, cracks, corrosion, or other damage on the cylinder body and valve.

- Hydrostatic testing: Subjecting the cylinder to high pressure to test its structural integrity and identify any weaknesses.

- Valve testing: Verifying the proper operation and sealing of the cylinder valve, including leak testing.

- Record keeping: Documenting the inspection and test results, including the date, cylinder identification, and any identified defects or repairs.

- Certification: Issuing a certificate or tag indicating the cylinder has passed inspection and testing and is compliant with industry standards.

6. How do you ensure the proper calibration and maintenance of pressure gauges and other instrumentation used with compressed gas equipment?

- Regular calibration: Using certified calibration equipment and procedures to ensure accuracy and reliability.

- Preventive maintenance: Inspecting and cleaning pressure gauges and instrumentation regularly to prevent malfunctions and ensure optimal performance.

- Documentation: Recording calibration and maintenance records to track the status and history of the equipment.

- Training: Ensuring that technicians are trained on proper calibration and maintenance techniques.

- Collaboration: Working with certified calibration laboratories or manufacturers to ensure the highest level of accuracy and compliance.

7. Explain the importance of following manufacturer’s instructions and industry best practices when servicing compressed gas equipment.

- Safety: Adhering to manufacturer’s instructions and best practices minimizes risks and ensures safe operation of compressed gas equipment.

- Reliability: Following proper procedures helps prevent equipment failures and extends its lifespan.

- Compliance: Meeting industry standards and regulations demonstrates responsible operation and reduces legal liability.

- Warranty: Maintaining equipment according to manufacturer’s specifications preserves warranty coverage.

- Efficiency: Using approved methods and techniques optimizes equipment performance and reduces downtime.

8. Describe a challenging repair or maintenance project involving compressed gas equipment and how you resolved it.

- Provide a brief description of the project and the specific challenges encountered.

- Explain the steps taken to diagnose the problem, including any specialized tools or techniques used.

- Describe the repair or maintenance solution implemented and the outcome achieved.

- Highlight any lessons learned or best practices gained from the experience.

9. Discuss the importance of staying up-to-date with industry advancements and regulations related to compressed gas equipment.

- Safety: New technologies and regulations often enhance safety measures and reduce risks.

- Compliance: Staying informed ensures adherence to evolving industry standards and legal requirements.

- Efficiency: Advanced equipment and techniques can improve productivity and reduce operating costs.

- Career growth: Demonstrating knowledge of industry advancements shows commitment to professional development.

- Reputation: Companies that prioritize staying up-to-date are seen as reliable and trustworthy.

10. How do you prioritize and manage multiple service requests for compressed gas equipment?

- Triage: Assessing the urgency and criticality of each request based on safety, production impact, or other factors.

- Scheduling: Optimizing a schedule that balances workload, availability of resources, and customer needs.

- Communication: Keeping customers informed about service status, estimated arrival times, and any potential delays.

- Resource allocation: Assigning technicians and equipment based on their skills and availability.

- Follow-up: Ensuring that service requests are completed satisfactorily and customer concerns are addressed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compressed Gas Equipment Service Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compressed Gas Equipment Service Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Compressed Gas Equipment Service Mechanics specialize in maintaining and repairing a wide range of gas equipment, including cylinders, valves, regulators, and compressors. They play a crucial role in ensuring the safe and efficient operation of these systems. Here are their key responsibilities:

1. Maintenance and Inspection

Inspect and test gas equipment to identify any potential issues or malfunctions.

- Conduct scheduled maintenance on cylinders, valves, regulators, and compressors.

- Clean and lubricate components to prevent corrosion and ensure smooth operation.

2. Repairs and Troubleshooting

Diagnose and repair faulty or malfunctioning gas equipment.

- Identify and replace or repair damaged components.

- Resolve complex technical issues.

- Troubleshoot and resolve safety concerns.

3. Safety Compliance

Ensure gas equipment meets all safety regulations and standards.

- Inspect and certify gas cylinders and tanks.

- Follow strict safety protocols.

- Train and educate clients on safe gas equipment handling.

4. Customer Service

Provide excellent customer service by responding to inquiries and resolving issues promptly.

- Communicate effectively with clients.

- Provide technical support and advice.

- Maintain positive relationships with clients.

Interview Tips

Preparing thoroughly for an interview is crucial to making a great impression and increasing your chances of success. Here are some tips to help you ace the interview for a Compressed Gas Equipment Service Mechanic position:

1. Research the Company and Role

Before the interview, spend time thoroughly researching the company and the specific role you are applying for. This will demonstrate your genuine interest and enthusiasm for the position.

- Visit the company’s website to gather information about their history, culture, and values.

- Read industry news and articles to stay updated on the latest trends and developments.

2. Highlight Relevant Experience and Skills

Tailor your resume and cover letter to showcase your relevant experience and skills that align with the job requirements. Use specific examples to demonstrate your abilities in:

- Gas equipment maintenance and repair.

- Troubleshooting and problem-solving.

- Safety compliance.

- Customer service.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. Some likely questions include:

- Tell me about your experience maintaining and repairing gas equipment.

- Describe a time when you successfully resolved a complex technical issue.

- How do you ensure compliance with safety regulations in your work?

- How do you prioritize and manage your workload effectively?

4. Be Confident and Enthusiastic

Confidence and enthusiasm are essential during an interview. Maintain a positive attitude, make eye contact, and speak clearly and concisely. Let your genuine interest and passion for the role shine through.

- Dress professionally and arrive on time for your interview.

- Be respectful and polite to everyone you meet.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Compressed Gas Equipment Service Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!