Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Compressed Gas Plant Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

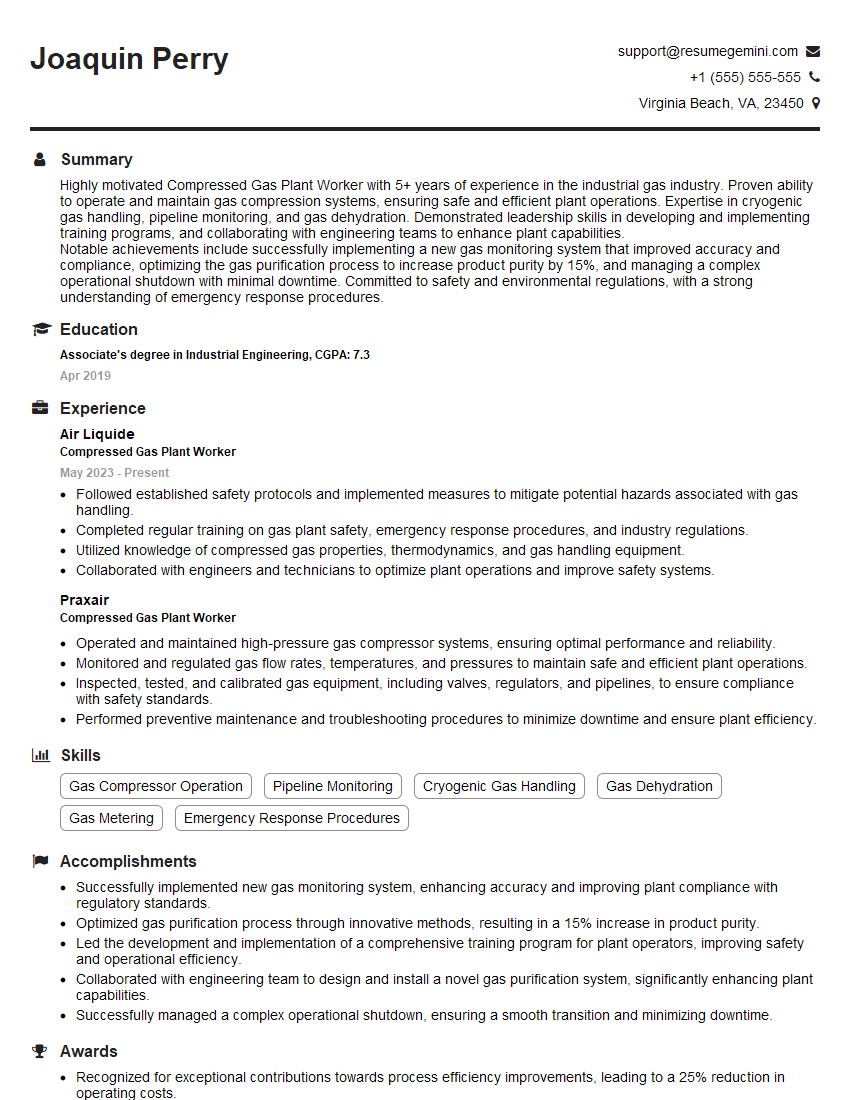

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compressed Gas Plant Worker

1. Explain the different types of compressed gases used in industrial applications?

Compressed gases are used in a wide range of industrial applications, including:

- Welding and cutting

- Medical applications

- Food processing

- Chemical processing

- Aerospace

2. Describe the various methods for storing and handling compressed gases?

Storage Methods

- Cylinders

- Tanks

- Tubes

Handling Methods

- Always use proper PPE

- Inspect equipment regularly

- Store gases in a well-ventilated area

- Never mix different gases

3. What are the potential hazards associated with working with compressed gases?

The potential hazards associated with working with compressed gases include:

- Explosion

- Fire

- Asphyxiation

- Skin and eye irritation

- Frostbite

4. How do you ensure the safety of yourself and others when working with compressed gases?

To ensure the safety of myself and others when working with compressed gases, I always:

- Follow all safety protocols

- Use proper PPE

- Inspect equipment regularly

- Store gases in a well-ventilated area

- Never mix different gases

- Be aware of the potential hazards

- Train regularly

5. What are the different types of compressors used for compressing gases?

- Reciprocating compressors

- Rotary screw compressors

- Centrifugal compressors

- Axial compressors

6. Explain the principles of operation of a reciprocating compressor?

A reciprocating compressor is a positive displacement compressor that uses a piston to compress a gas. The piston moves back and forth in a cylinder, compressing the gas and forcing it out of the cylinder.

7. What are the advantages and disadvantages of using a rotary screw compressor?

Advantages

- Quiet operation

- Oil-free operation

- High efficiency

Disadvantages

- More expensive than reciprocating compressors

- Not as durable as reciprocating compressors

8. How do you troubleshoot a centrifugal compressor?

To troubleshoot a centrifugal compressor, I would:

- Check the inlet and outlet pressures

- Check the speed of the compressor

- Check the temperature of the compressor

- Check the lubrication system

- Check the seals

9. What are the different types of gas detection systems used in compressed gas plants?

- Infrared gas detectors

- Ultrasonic gas detectors

- Electrochemical gas detectors

- Catalytic bead gas detectors

10. How do you calibrate a gas detection system?

To calibrate a gas detection system, I would:

- Use a known concentration of gas

- Expose the sensor to the gas

- Adjust the sensor until it reads the correct concentration

- Repeat the process for different concentrations of gas

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compressed Gas Plant Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compressed Gas Plant Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Compressed Gas Plant Worker is the frontline of the natural gas industry responsible for handling compressed gas at production or storage facilities. This challenging role involves operating, maintaining, troubleshooting, and repairing equipment, ensuring the safe and efficient production and storage of compressed natural gas.

1. Gas Compression and Storage

Operate gas compressors to compress natural gas, increasing its pressure for storage and transportation.

- Monitor and maintain gas pressure, flow rates, and temperatures to ensure optimal compression efficiency.

- Inspect and repair gas pipelines, storage tanks, and associated equipment to prevent leaks and maintain system integrity.

2. Equipment Maintenance and Repair

Perform preventive maintenance and repairs to gas compressors, engines, and other plant machinery.

- Troubleshoot and diagnose equipment malfunctions, using specialized tools and techniques.

- Replace worn or damaged components, ensuring the smooth operation of the plant.

3. Safety and Emergency Response

Adhere to strict safety protocols and emergency procedures to protect personnel and the facility.

- Monitor gas detection systems to detect potential leaks or hazards and take appropriate actions.

- Respond to emergencies, such as gas leaks, fires, or equipment failure, following established procedures.

4. Data Monitoring and Reporting

Record and report data on gas production, storage, and equipment performance.

- Maintain accurate logs and records for plant operations and maintenance activities.

- Provide regular reports to supervisors and management on plant performance and potential issues.

Interview Tips

To ace your interview for a Compressed Gas Plant Worker position, consider the following tips and preparation techniques:

1. Research the Company and Role

Thoroughly research the company and the specific role you are applying for. Understand their business, values, and the responsibilities of the position.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that directly align with the job requirements. Quantify your accomplishments whenever possible using specific examples.

3. Prepare for Technical Questions

Expect technical questions related to gas compression, equipment maintenance, and safety protocols. Study basic gas compression principles and demonstrate your understanding.

4. Demonstrate Safety Awareness

The safety of the plant and its personnel is paramount. Highlight your knowledge of safety regulations, emergency procedures, and your commitment to maintaining a safe work environment.

5. Practice Common Interview Questions

Rehearse answers to common interview questions such as “Why are you interested in this role?” and “What are your strengths and weaknesses?”.

6. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions about the plant’s operations, growth opportunities, and company culture.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Compressed Gas Plant Worker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.