Are you gearing up for a career in Compressed Yeast Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Compressed Yeast Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

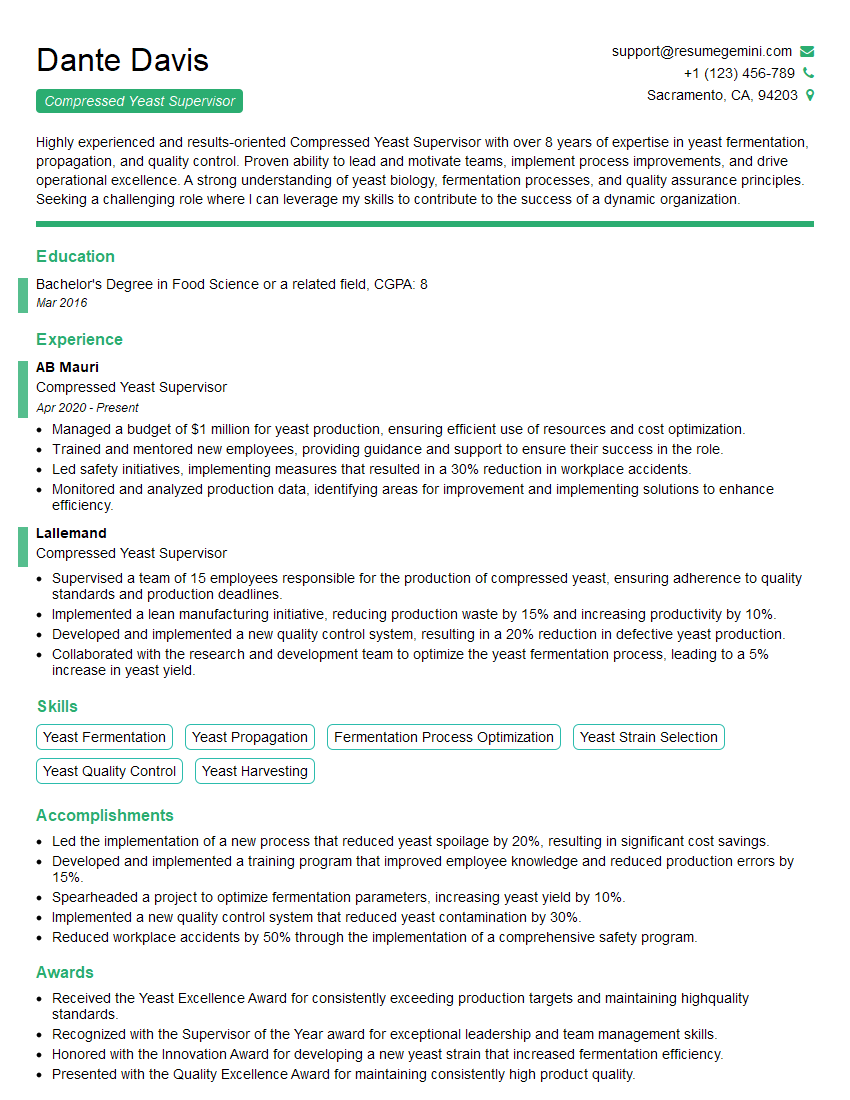

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compressed Yeast Supervisor

1. What are the key performance indicators (KPIs) you would use to measure the performance of a compressed yeast production line?

The following are the key performance indicators (KPIs) that I would use to measure the performance of a compressed yeast production line:

- Production output: This measures the amount of compressed yeast produced per hour or per shift.

- Product quality: This measures the percentage of compressed yeast that meets the desired specifications.

- Downtime: This measures the percentage of time that the production line is not operating due to breakdowns or maintenance.

- Yield: This measures the amount of compressed yeast produced per unit of raw material input.

- Cost of production: This measures the total cost of producing a unit of compressed yeast.

2. What are the common quality issues that can occur during compressed yeast production and how would you address them?

- Contamination: This can be caused by bacteria, mold, or other microorganisms. To address this, I would ensure that the production environment is clean and sterile, and that the raw materials and equipment are free of contamination.

- Low fermentation activity: This can be caused by a variety of factors, including the use of old or inactive yeast, or the presence of inhibitors in the fermentation medium. To address this, I would ensure that the yeast is fresh and active, and that the fermentation medium is free of inhibitors.

- Off-flavors or odors: This can be caused by the presence of volatile compounds in the fermentation medium or by the growth of undesirable microorganisms. To address this, I would identify the source of the off-flavors or odors and take steps to eliminate them.

3. Describe the key steps involved in the production of compressed yeast.

The key steps involved in the production of compressed yeast are as follows:

- Propagation: The yeast is grown in a nutrient-rich medium to increase the cell population.

- Harvesting: The yeast cells are separated from the fermentation medium.

- Washing: The yeast cells are washed to remove any impurities.

- Concentration: The yeast cells are concentrated by centrifugation or filtration.

- Pressing: The yeast cells are pressed to remove excess water.

- Packaging: The compressed yeast is packaged in blocks or other suitable containers.

4. What are the safety considerations that must be taken into account when working with compressed yeast?

- Compressed yeast is a biological material and can contain microorganisms that can cause infections. To prevent this, it is important to wear gloves and a mask when handling compressed yeast, and to wash your hands thoroughly afterwards.

- Compressed yeast can produce carbon dioxide gas, which can be hazardous if it is not properly vented. To prevent this, it is important to ensure that the production area is well-ventilated.

- Compressed yeast can be slippery, so it is important to take precautions to prevent falls. To do this, wear non-slip shoes and keep the work area clean and dry.

5. What are the latest trends in compressed yeast production?

- The use of new technologies to improve fermentation efficiency and product quality.

- The development of new yeast strains with improved performance characteristics.

- The increasing use of compressed yeast in food and beverage applications.

6. What are the challenges facing the compressed yeast industry?

- The increasing cost of raw materials.

- The competition from other yeast products.

- The need to meet the growing demand for compressed yeast.

7. How would you manage a team of compressed yeast production operators?

- I would set clear goals and expectations for my team.

- I would provide my team with the training and resources they need to be successful.

- I would motivate and inspire my team to achieve their goals.

- I would create a positive and supportive work environment.

- I would recognize and reward my team for their contributions.

8. How would you improve the efficiency of a compressed yeast production line?

- I would identify and eliminate bottlenecks.

- I would improve the efficiency of the fermentation process.

- I would optimize the harvesting and washing processes.

- I would implement a preventive maintenance program.

- I would train my team on best practices.

9. What are your strengths and weaknesses as a compressed yeast production supervisor?

-

Strengths:

- I have a strong understanding of the compressed yeast production process.

- I have experience in managing a team of production operators.

- I am a results-oriented and detail-oriented individual. Weaknesses:

- I am new to the compressed yeast industry.

- I do not have experience in working with a large-scale production line.

10. What are your career goals?

My career goal is to become a plant manager in the compressed yeast industry. I am confident that I have the skills and experience necessary to be successful in this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compressed Yeast Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compressed Yeast Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Compressed Yeast Supervisor is a key member of the production team in a yeast manufacturing facility. They are responsible for overseeing the production of compressed yeast, ensuring that it meets quality standards and is produced efficiently. Key job responsibilities include:

1. Production Planning and Scheduling

Supervises and coordinates all aspects of compressed yeast production, including planning, scheduling, and execution.

- Develops and monitors production schedules to ensure timely delivery of products.

- Ensures that production processes are optimized for efficiency and quality.

2. Quality Control and Assurance

Maintains high standards of quality control and ensures that compressed yeast meets all specifications.

- Establishes and implements quality control procedures.

- Conducts regular inspections of production processes and products.

- Investigates and resolves quality issues promptly.

3. Team Management and Supervision

Supervises and motivates a team of production operators, ensuring that they are trained, efficient, and productive.

- Provides training and development to production staff.

- Monitors employee performance and provides feedback.

4. Equipment Maintenance and Troubleshooting

Ensures that all production equipment is maintained and operating properly.

- Conducts regular maintenance and inspection of equipment.

- Troubleshoots and resolves equipment problems promptly.

Interview Tips

To help you ace your interview for a Compressed Yeast Supervisor position, here are some tips and tricks:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will give you a good understanding of the company’s culture, goals, and the specific requirements of the role. You can find this information on the company website, social media pages, and industry publications.

- Read the job description carefully and identify the key skills and responsibilities required for the role.

- Visit the company’s website to learn about their history, mission, and values.

2. Practice Your Answers

One of the best ways to prepare for an interview is to practice your answers to common interview questions. This will help you feel more confident and articulate during the interview. You can practice answering questions with a friend, family member, or career counselor.

- Prepare answers to questions about your experience, skills, and why you are interested in the position.

- Use the STAR method to answer questions by providing specific examples of your accomplishments.

3. Be Enthusiastic and Professional

During the interview, it is important to be enthusiastic and professional. This will show the interviewer that you are interested in the position and that you are a good fit for the team. Be sure to make eye contact, speak clearly, and dress appropriately.

- Arrive on time for your interview and be prepared to answer questions about your experience and qualifications.

- Be respectful of the interviewer’s time and answer questions honestly and concisely.

4. Ask Questions

At the end of the interview, be sure to ask questions about the position and the company. This shows the interviewer that you are interested in the role and that you are taking the interview seriously. You can also ask about the company’s culture, goals, and opportunities for advancement.

- Prepare a few questions to ask the interviewer about the position, the team, and the company.

- Asking questions shows that you are engaged and interested in the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Compressed Yeast Supervisor role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.