Are you gearing up for a career in Compressor Assembler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Compressor Assembler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

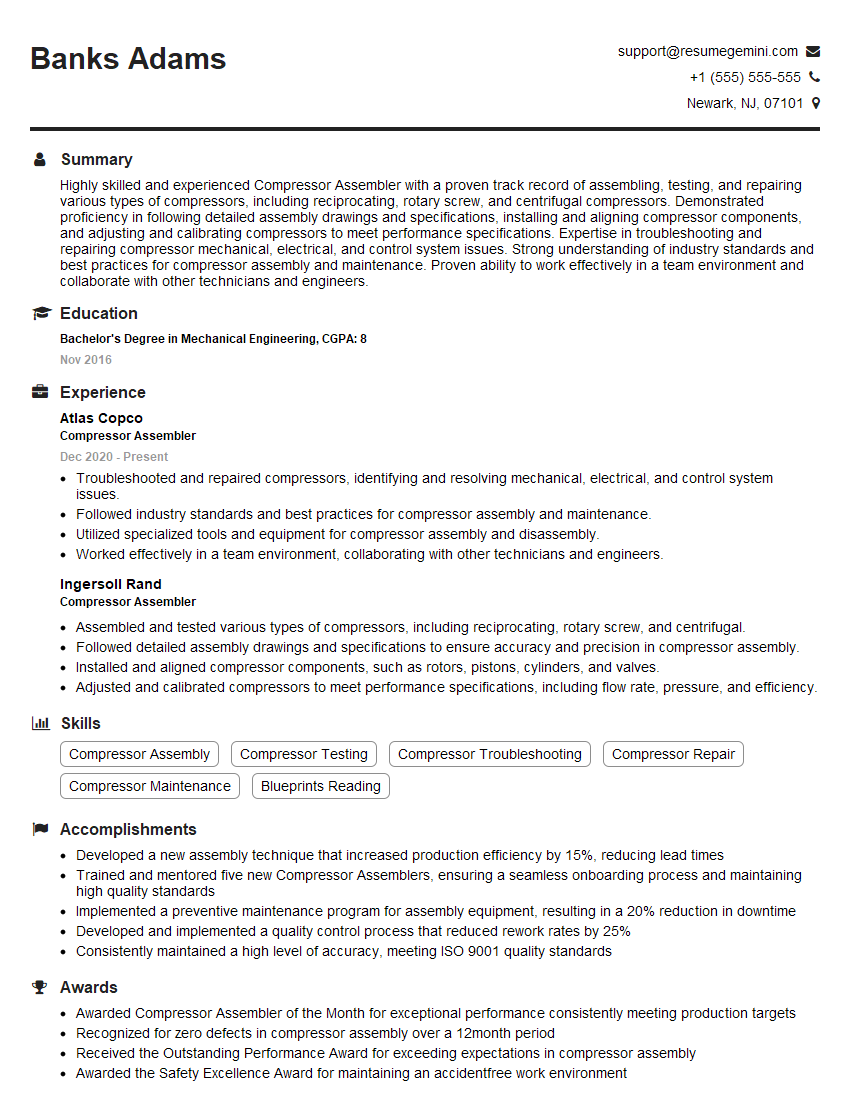

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compressor Assembler

1. What are the primary responsibilities of a Compressor Assembler?

The primary responsibilities of a Compressor Assembler typically include:

- Assembling and installing compressor components

- Inspecting and testing compressors

- Maintaining and repairing compressors

- Troubleshooting and resolving compressor issues

- Adhering to safety protocols and maintaining a clean work area

2. Explain the different types of compressors and their applications.

- Reciprocating compressors: Used in various applications, including industrial refrigeration, air conditioning, and automotive engines.

- Rotary screw compressors: Commonly employed in industrial applications, such as manufacturing and power generation, due to their high efficiency and reliability.

- Centrifugal compressors: Used in large-scale industrial applications, such as gas turbines and chemical processing, where high flow rates and pressures are required.

- Axial compressors: Found in jet engines and gas turbines, designed to handle high volumes of air at relatively low pressures.

3. Describe the assembly process of a reciprocating compressor.

The assembly process of a reciprocating compressor typically involves the following steps:

- Preparing the compressor housing and components

- Assembling the crankshaft and connecting rod

- Installing the piston and piston rings

- Mounting the cylinder head

- Connecting the valves and piping

- Lubricating and testing the compressor

4. How do you ensure the quality and performance of the compressors you assemble?

To ensure quality and performance, I adhere to the following practices:

- Thorough inspection: Inspecting all components for defects or damage before assembly.

- Precise assembly: Following assembly instructions meticulously and using appropriate tools and techniques.

- Rigorous testing: Conducting performance tests to verify compressor specifications and identify any potential issues.

- Documentation: Maintaining detailed records of assembly and testing procedures for traceability and quality control.

5. What are the common troubleshooting techniques used for compressor issues?

- Electrical diagnostics: Verifying power supply, wiring, and electrical components.

- Mechanical inspection: Examining moving parts, bearings, and seals for wear or damage.

- Refrigerant analysis: Checking refrigerant levels, pressure, and contamination.

- Performance testing: Monitoring compressor performance parameters, such as pressure, flow rate, and efficiency.

6. How do you stay updated with the latest advancements and technologies in compressor assembly?

To stay updated, I engage in the following activities:

- Industry publications: Reading technical journals and articles to learn about new products, techniques, and industry trends.

- Training and workshops: Attending manufacturer-sponsored training programs and workshops to enhance my skills and knowledge.

- Online resources: Utilizing online forums, discussion groups, and manufacturer websites to connect with other professionals and access technical information.

7. What safety precautions should be taken when working with compressors?

- Proper PPE: Wearing appropriate personal protective equipment, including safety glasses, gloves, and hearing protection.

- Electrical safety: Ensuring proper grounding and isolation of electrical components.

- Pressure handling: Carefully handling compressed air and refrigerants, and using pressure relief valves to prevent over-pressurization.

- Machine guarding: Ensuring that all moving parts are properly guarded to prevent contact and injury.

8. How do you prioritize and manage multiple compressor assembly tasks effectively?

- Task prioritization: Assessing the urgency and importance of each task based on customer needs and deadlines.

- Time management: Utilizing time management techniques, such as task lists and scheduling, to allocate time effectively.

- Delegation: Assigning tasks to colleagues or team members when appropriate to optimize workload distribution.

- Communication: Keeping supervisors and colleagues informed of progress and any potential delays or challenges.

9. What is your understanding of the importance of maintaining accurate documentation in compressor assembly?

Accurate documentation plays a vital role in compressor assembly for several reasons:

- Quality control: Provides a record of assembly procedures and test results, allowing for traceability and verification of quality.

- Troubleshooting: Serves as a reference for troubleshooting and identifying the root cause of any issues that may arise.

- Compliance: Helps ensure compliance with industry standards and regulatory requirements.

- Knowledge transfer: Facilitates the sharing of knowledge and best practices with other technicians and team members.

10. How do you handle situations where you encounter technical challenges or unexpected issues during compressor assembly?

- Troubleshooting: Systematically identifying and analyzing the issue to determine the root cause.

- Research: Consulting technical documentation, online resources, and consulting with colleagues to find solutions.

- Collaboration: Seeking assistance from supervisors, engineers, or other technicians to resolve complex issues.

- Adaptability: Modifying assembly procedures or finding alternative solutions to overcome challenges while maintaining safety and quality standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compressor Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compressor Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Compressor Assembler is responsible for overseeing the assembling process within a manufacturing setting, ensuring the efficient and accurate construction of compressors and their components. Specific responsibilities include:

1. Assemble and Test Compressors

Expertly assembling various compressor models, properly connecting components, and conducting thorough functional testing to ensure optimal performance.

- Reading and interpreting engineering drawings and specifications

- Calibrating and maintaining assembly tools and equipment

- Identifying and resolving assembly problems promptly

2. Manage Inventory

Maintaining inventory levels and effectively managing parts and materials, ensuring a smooth and efficient assembly process.

- Monitoring inventory levels and reordering supplies as needed

- Organizing and maintaining a clean and well-stocked work area

- Identifying and tracking damaged or defective parts

3. Troubleshooting and Repair

Troubleshooting and repairing compressors and their components, using technical expertise to quickly identify and resolve issues.

- Diagnosing malfunctions and identifying the root cause of problems

- Performing repairs and replacements of defective parts

- Calibrating and adjusting compressors to meet performance specifications

4. Quality Control

Maintaining high quality standards throughout the assembly process, ensuring that compressors meet or exceed customer expectations.

- Conducting quality checks at various stages of assembly

- Inspecting finished products for accuracy and completeness

- Identifying and correcting defects before compressors are shipped

Interview Tips

To ace an interview for a Compressor Assembler position, it’s crucial to highlight your technical skills, problem-solving abilities, and attention to detail. Here are some interview tips to help you prepare:

1. Research the Company and Role

Thoroughly research the company’s background, industry, and specific product offerings. This will demonstrate your interest and understanding of their business.

- Visit the company website and social media pages

- Review industry news and articles

- Practice answering questions about your understanding of the company and the industry

2. Showcase Your Technical Skills

Highlight your technical abilities and experience relevant to compressor assembly. Quantify your accomplishments and provide specific examples.

- Discuss your experience with different compressor models and their components

- Quantify your assembly rates and quality metrics

- Explain your knowledge of assembly tools and equipment

3. Emphasize Problem-Solving Abilities

Demonstrate your ability to troubleshoot and resolve problems efficiently. Provide examples of how you have solved assembly issues in the past.

- Describe a situation where you identified and resolved a complex assembly problem

- Explain your approach to troubleshooting and problem-solving

- Highlight your ability to work under pressure and meet deadlines

4. Highlight Attention to Detail

Emphasize your attention to detail and commitment to quality. Describe how you ensure accuracy in your work.

- Explain your quality control processes and how you ensure the accuracy of assembled compressors

- Discuss your experience with adhering to assembly specifications and standards

- Highlight your commitment to meeting or exceeding customer expectations

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Compressor Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!