Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Compressor Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

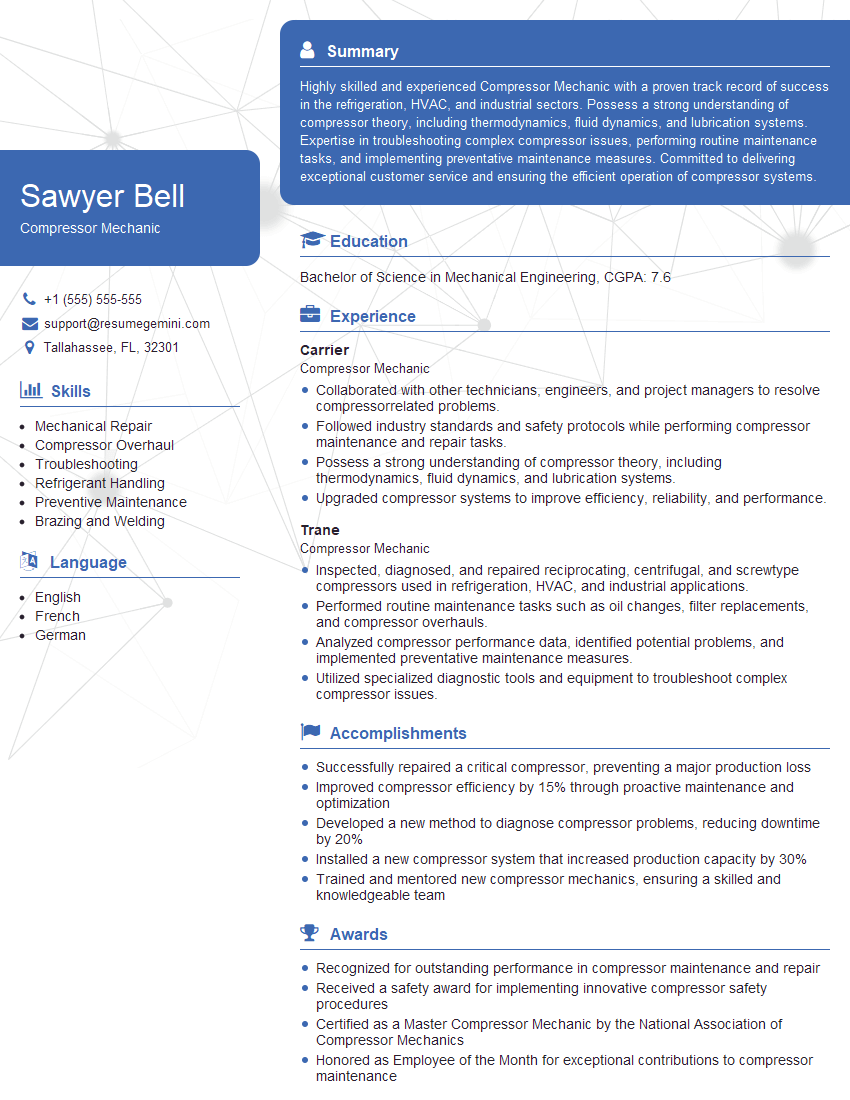

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compressor Mechanic

1. What are the different types of compressors?

There are 3 main types of Compressors

- Positive Displacement Compressors: In positive displacement compressors, gas is trapped in a volume and its volume is mechanically reduced. This increases the pressure of the gas. Rotary screw compressors and reciprocating compressors are common examples of positive displacement compressors.

- Dynamic Compressors: Dynamic compressors use the kinetic energy of rotating blades or impellers to accelerate the gas and increase its pressure. Centrifugal compressors and axial compressors are commonly used dynamic compressors.

- Mixed Flow Compressors: Mixed flow compressors combine features of both positive displacement and dynamic compressors. They trap some gas in a volume and then accelerate the gas to increase its pressure.

2. What are the factors to consider when selecting a compressor?

Factors to consider while selecting compressor

- Pressure and flow rate requirements

- Type of gas being compressed

- Operating environment

- Cost and maintenance requirements

Factors to consider while selecting compressor vendor

- Experience and reputation

- Product quality and reliability

- Customer service and support

- Price and payment terms

3. What are the common problems associated with compressors?

Common problems associated with compressors may include

- Leakage

- Overheating

- Vibration

- Noise

- Contamination

- Electrical problems

- Mechanical problems

4. How do you troubleshoot a compressor?

To troubleshoot a compressor, you need to follow the following steps

- Identify the problem

- Check the power supply

- Check the compressor’s oil level

- Check the compressor’s air filter

- Check the compressor’s valves

- Check the compressor’s belts

- Check the compressor’s bearings

- Check the compressor’s electrical connections

- Check the compressor’s refrigerant level

5. What are the safety precautions that should be taken when working with compressors?

Safety precautions when working with compressors include

- Wear appropriate safety gear

- Read and understand the compressor’s manual

- Follow the manufacturer’s instructions

- Inspect the compressor regularly

- Service the compressor regularly

- Store the compressor in a safe place

6. What is the difference between a reciprocating compressor and a rotary screw compressor?

Reciprocating Compressor

- Uses a piston to compress gas

- Positive displacement compressor

- Suitable for high pressure applications

- Less efficient than rotary screw compressors

Rotary Screw Compressor

- Uses two intermeshing screws to compress gas

- Positive displacement compressor

- Suitable for low to medium pressure applications

- More efficient than reciprocating compressors

7. What is the purpose of an air compressor oil separator?

- To remove oil from the compressed air

- To protect downstream equipment from oil contamination

- To improve the efficiency of the compressor

8. How do you calculate the horsepower of a compressor?

Horsepower of a compressor can be calculated using the following formula

- Horsepower = (Pressure x Flow rate) / 33000

- Where

- Pressure is in psi

- Flow rate is in cubic feet per minute (cfm)

9. What is the difference between a single-stage compressor and a multi-stage compressor?

Single-stage compressor

- Compresses gas in one stage

- Lower pressure ratio

- Less efficient than multi-stage compressors

Multi-stage compressor

- Compresses gas in multiple stages

- Higher pressure ratio

- More efficient than single-stage compressors

10. What are the advantages of using a variable speed drive (VSD) with a compressor?

- Improved efficiency

- Reduced energy consumption

- Extended compressor life

- Reduced noise levels

- Improved process control

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compressor Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compressor Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Compressor Mechanics carry out a range of duties to ensure that the compressors they work on are operating at maximum efficiency. Their key job responsibilities include:

1. Maintenance and Repair

Servicing, inspecting, and adjusting compressors to prevent breakdowns

- Inspecting lubrication systems, belts, bearings, and seals

- Monitoring pressure, temperature, and flow parameters

2. Troubleshooting

Diagnosing and solving problems with compressors

- Analyzing symptoms and using diagnostic tools to identify the root cause of problems

- Recommending and implementing repairs to restore compressor functionality

3. Installation and Commissioning

Installing new compressors and ensuring they are operational

- Following installation and commissioning procedures to ensure proper setup and operation

- Testing and adjusting compressors to meet performance specifications

4. Overhaul and Rebuilding

Performing extensive repairs and overhauls on compressors

- Replacing major components such as rotors, bearings, and seals

- Restoring compressors to their original specifications

Interview Tips

To help you ace your Compressor Mechanic interview, consider the following tips:

1. Research the role and company

Before the interview, research the specific role and the company to gain insights into their operations, industry trends, and unique requirements.

- Visit the company’s website to learn about their business, values, and compressor-related services.

- Study the job description thoroughly to identify key responsibilities and qualifications.

2. Practice answering common interview questions

Prepare for common interview questions related to your skills, experience, and knowledge of compressor mechanics. Consider the following examples and prepare your responses accordingly:

- Tell me about your experience in compressor maintenance and repair.

- Describe a time when you successfully diagnosed and resolved a complex compressor issue.

- What are the different types of compressors and their applications?

- How do you stay updated with the latest advancements in compressor technology?

- Why are you interested in working for our company as a Compressor Mechanic?

3. Highlight your technical expertise

Emphasize your technical skills and knowledge of compressor systems, including:

- Proficiency in compressor troubleshooting and repair techniques

- Understanding of compressor design, operation, and maintenance principles

- Familiarity with different types of compressors (e.g., reciprocating, rotary, centrifugal)

- Ability to read and interpret technical drawings and schematics

- Knowledge of safety regulations and best practices for compressor operations

4. Showcase your problem-solving abilities

In your interview, demonstrate your problem-solving skills by providing specific examples of how you have identified and resolved compressor issues:

- Describe how you used diagnostic tools and techniques to pinpoint the root cause of a compressor failure.

- Explain the steps you took to develop and implement effective repair solutions to restore compressor functionality.

- Share instances where you used your analytical skills to optimize compressor performance and efficiency.

5. Emphasize your communication and interpersonal skills

Highlight your communication skills, ability to work independently, and collaborate effectively in a team environment:

- Describe how you effectively communicate technical information to both technical and non-technical stakeholders.

- Provide examples of how you have successfully worked with colleagues and supervisors to resolve complex compressor issues.

- Explain your approach to managing your time and prioritizing tasks efficiently.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Compressor Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!