Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Compressor Room Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Compressor Room Operator so you can tailor your answers to impress potential employers.

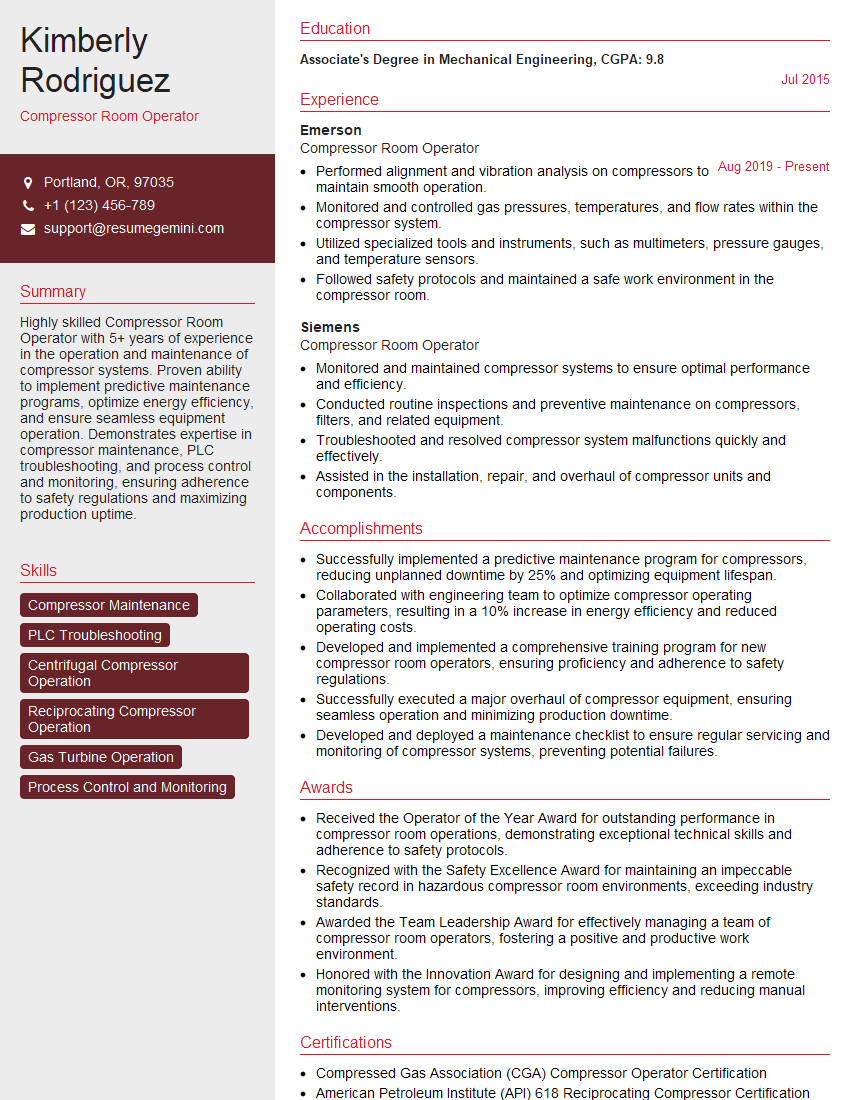

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compressor Room Operator

1. What are the different types of compressors used in a compressor room?

There are various types of compressors commonly used in a compressor room, including:

- Reciprocating compressors: Positive displacement compressors with pistons moving within cylinders, suitable for high-pressure applications.

- Rotary screw compressors: Positive displacement compressors with intermeshing screws, providing continuous airflow with low noise and vibration.

- Centrifugal compressors: Dynamic compressors using rotating impellers to increase gas pressure, ideal for large-scale operations.

- Axial compressors: Dynamic compressors with multiple rows of rotating and stationary blades, generating high-pressure ratios.

2. What are the key performance indicators (KPIs) you monitor for compressor operation?

Compressor Efficiency

- Specific power consumption (kW/m3/min) or isentropic efficiency

- Volumetric efficiency (actual flow rate vs. theoretical flow rate)

Compressor Reliability

- Mean time between failures (MTBF)

- Mean time to repair (MTTR)

Compressor Capacity

- Actual flow rate (m3/min) or pressure ratio

- Capacity utilization (actual flow rate vs. design flow rate)

3. Describe the steps involved in starting up and shutting down a compressor.

Compressor Startup Procedure:

- Verify system conditions (e.g., temperature, pressure, lubrication).

- Start auxiliary systems (e.g., cooling water, lubrication pumps).

- Slowly open suction and discharge valves.

- Start compressor motor and monitor operating parameters.

Compressor Shutdown Procedure:

- Gradually close discharge valve.

- Stop compressor motor.

- Close suction valve.

- Stop auxiliary systems.

4. How do you handle compressor failures?

When a compressor fails, I follow a systematic approach to troubleshoot and resolve the issue:

- Identify the symptoms: Observe and record any abnormal noises, vibrations, or readings.

- Check safety systems: Verify the status of alarms, interlocks, and protective devices.

- Consult technical manuals: Refer to manufacturer’s instructions for troubleshooting procedures.

- Perform diagnostic tests: Conduct electrical, mechanical, or vibration analysis to isolate the fault.

- Repair or replace components: If necessary, replace faulty parts or repair damaged components.

- Test and verify operation: Once repairs are made, perform testing to ensure the compressor operates properly.

5. What measures do you take to prevent compressor breakdowns?

To prevent compressor breakdowns, I prioritize the following measures:

- Regular maintenance: Adhere to manufacturer’s maintenance schedules for inspections, oil changes, and filter replacements.

- Condition monitoring: Utilize sensors and monitoring systems to track operating parameters and detect potential issues early on.

- Predictive maintenance: Perform vibration analysis, oil analysis, and other predictive maintenance techniques to identify potential failures before they occur.

- Proper operating procedures: Ensure operators follow correct startup, shutdown, and operating procedures to minimize stress on the compressor.

6. How do you optimize compressor performance and efficiency?

To optimize compressor performance and efficiency, I implement the following strategies:

- Capacity control: Adjust compressor output to match system demand using variable speed drives or inlet guide vanes.

- Pressure optimization: Maintain optimal discharge pressure to minimize energy consumption while meeting system requirements.

- Leakage reduction: Regularly inspect and seal any potential leakages in the system to prevent loss of compressed air.

- Proper lubrication: Ensure adequate and timely lubrication to minimize friction and wear.

7. What safety precautions do you observe when working in a compressor room?

In a compressor room, I prioritize the following safety precautions:

- Personal protective equipment: Wear appropriate PPE, including hearing protection, safety glasses, and gloves.

- Lockout/tagout procedures: Follow established procedures to isolate and de-energize equipment before performing maintenance or repairs.

- Confined space entry: Adhere to proper procedures when entering enclosed spaces, such as compressor housings.

- Awareness of potential hazards: Be aware of potential hazards, such as high pressure, electrical hazards, and noise.

8. How do you stay up-to-date with advancements in compressor technology?

To stay current with advancements in compressor technology, I employ the following strategies:

- Attend industry conferences and workshops: Participate in events that showcase new technologies and best practices.

- Read technical publications and journals: Stay informed about the latest research and developments in the field.

- Network with peers and experts: Engage with industry professionals to exchange knowledge and learn about emerging technologies.

9. How do you handle multiple tasks and prioritize your work in a fast-paced environment?

In a fast-paced environment, I prioritize my work and manage multiple tasks effectively through the following strategies:

- Time management: Utilize time management tools and techniques, such as to-do lists and schedules, to allocate time efficiently.

- Prioritization: Identify the most critical tasks and focus on completing them first.

- Delegation: When appropriate, delegate tasks to qualified individuals to distribute the workload.

- Communication: Maintain clear and regular communication with colleagues to coordinate efforts and avoid overlaps.

10. What are your strengths and weaknesses as a Compressor Room Operator?

Strengths:

- Strong technical knowledge of compressor systems and their operation.

- Excellent troubleshooting and problem-solving skills.

- Experience in implementing preventative and predictive maintenance programs.

- Proven ability to work effectively in a fast-paced and demanding environment.

Weaknesses:

- Limited experience with certain specialized types of compressors.

- Still developing my leadership and supervisory skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compressor Room Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compressor Room Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Compressor Room Operator is responsible for overseeing the safe and efficient operation of a compressor room. They work in industries that use compressed air to power equipment and machinery, such as manufacturing, construction, and energy.

1. Monitor and Control Equipment

Monitor and control the operation of compressors, air dryers, and other equipment in the compressor room.

- Start, stop, and adjust equipment to maintain desired air pressure and flow rate.

- Monitor gauges and instruments to ensure equipment is operating within normal parameters.

2. Maintain and Repair Equipment

Perform routine maintenance and repairs on compressor room equipment as needed.

- Lubricate and clean equipment.

- Replace filters and belts.

- Troubleshoot and resolve mechanical and electrical problems.

3. Monitor Energy Consumption

Monitor energy consumption and identify opportunities for improvement.

- Take readings from meters and gauges.

- Analyze data and make recommendations for energy-saving measures.

4. Ensure Safety

Ensure the safety of the compressor room and surrounding areas.

- Follow safety protocols and procedures.

- Wear appropriate personal protective equipment (PPE).

- Inspect equipment for potential hazards.

Interview Tips

To ace an interview for a Compressor Room Operator position, it’s important to prepare thoroughly. Here are some tips:

1. Research the Company and Position

Take the time to learn about the company you’re interviewing with, as well as the specific Compressor Room Operator position.

- Visit the company’s website and social media pages.

- Read industry news and articles.

- Network with people in the field.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you’re likely to be asked, such as:

- Tell me about your experience as a Compressor Room Operator.

- What are your strengths and weaknesses as a Compressor Room Operator?

- Why are you interested in this position?

Take some time to think about how you would answer these questions, and practice your answers out loud.

3. Be Prepared to Talk About Your Safety Knowledge

Safety is a top priority for Compressor Room Operators. Be prepared to talk about your knowledge of safety protocols and procedures.

- Discuss your experience with lockout/tagout procedures.

- Explain how you would respond to a safety emergency.

- Provide examples of how you have ensured the safety of others in the workplace.

4. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview.

- Wear a suit or dress pants and a button-down shirt.

- Make sure your shoes are clean and polished.

- Arrive at the interview location 10-15 minutes early.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Compressor Room Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!