Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Compressor Station Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Compressor Station Operator so you can tailor your answers to impress potential employers.

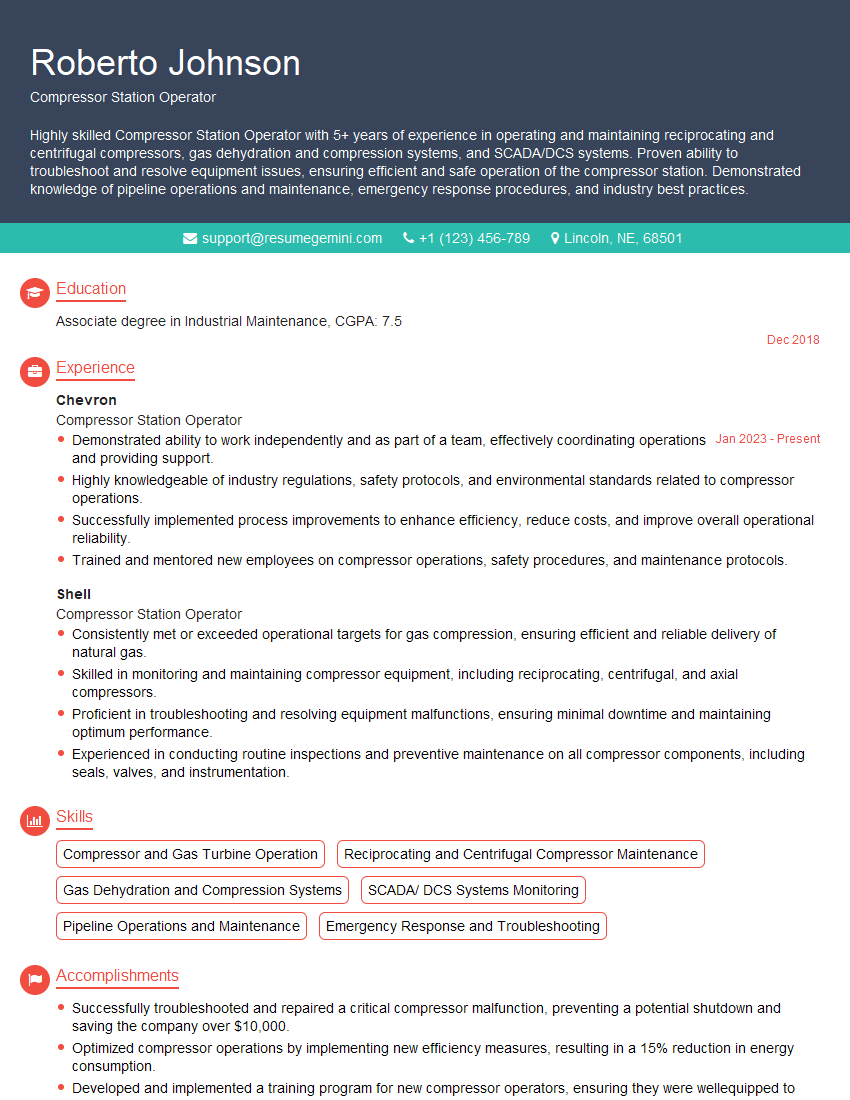

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compressor Station Operator

1. What is the main function of a compressor station?

A compressor station’s main function is to increase the pressure of a gas, usually natural gas, to facilitate its transportation through pipelines.

2. Describe the primary components of a compressor station.

- Intake Scrubber: Removes impurities and liquids from the incoming gas.

- Compressor: Increases the gas pressure.

- Aftercooler: Cools the gas after compression.

- Separator: Removes any remaining liquids or impurities.

- Discharge Scrubber: Removes any remaining impurities before the gas enters the pipeline.

3. How do you ensure the safe operation of a compressor station?

To ensure safe operation, I follow strict safety protocols, including:

- Regular equipment inspections and maintenance.

- Monitoring pressure, temperature, and other critical parameters.

- Adhering to established emergency procedures.

- Coordination with other team members and supervisors.

4. What types of compressors are commonly used in compressor stations?

- Reciprocating Compressors: Use pistons to compress the gas.

- Centrifugal Compressors: Use rotating impellers to increase the gas pressure.

- Screw Compressors: Utilize intermeshing screws to compress the gas.

5. How do you handle emergency situations at a compressor station?

In an emergency, I prioritize safety and follow established procedures:

- Identify the source of the emergency.

- Initiate appropriate safety measures.

- Notify supervisors and relevant personnel.

- Cooperate with emergency response teams.

6. What factors affect the efficiency of a compressor station?

- Compressor type and design.

- Gas composition and properties.

- Operating conditions (pressure, temperature).

- Maintenance and optimization practices.

7. How do you monitor and control the performance of a compressor station?

I use various tools and techniques to monitor and control performance:

- Control systems (SCADA, DCS).

- Performance indicators (pressure, flow rate, efficiency).

- Regular data analysis and reporting.

8. What are the common challenges faced by compressor station operators?

- Equipment breakdowns and maintenance issues.

- Gas quality variations.

- Environmental regulations and compliance.

- Ensuring safe and efficient operations.

9. How do you stay up-to-date with industry best practices and technological advancements?

- Attend industry conferences and workshops.

- Read technical literature and journals.

- Network with other professionals.

- Participate in training and development programs.

10. What are your strengths and weaknesses as a Compressor Station Operator?

- Strengths:

- Strong technical knowledge and experience.

- Excellent problem-solving and troubleshooting skills.

- Commitment to safety and compliance.

- Weaknesses:

- Limited experience with specific types of compressors.

- Need to improve communication skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compressor Station Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compressor Station Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Compressor Station Operator is responsible for the safe and efficient operation and maintanance of compressor stations in the oil and gas industry. They ensure that equipment is running smoothly, monitor systems, and respond to emergencies. Key responsibilities include:

1. Monitoring and Controlling Equipment

- Monitor and control compressors, pumps, valves, and other equipment to ensure efficient operation.

- Manage pressure, flow, temperature, and other system parameters to meet specifications.

2. Performing Maintenance and Repairs

- Perform routine maintenance tasks such as lubrication, cleaning, and inspections.

- Troubleshoot and repair equipment breakdowns, using knowledge of mechanical and electrical systems.

3. Ensuring Safety and Compliance

- Adhere to safety protocols and regulations to prevent accidents and injuries.

- Monitor environmental systems to ensure compliance with regulations.

4. Coordinating with Others

- Communicate with engineers, technicians, and supervisors to discuss operations and resolve issues.

- Work as part of a team to ensure smooth and efficient operations.

Interview Tips

To ace an interview for a Compressor Station Operator position, candidates should prepare by learning about the industry, researching the company, and practicing common interview questions. Here are some specific tips:

1. Research the Industry and Company

- Familiarize yourself with the oil and gas industry, including its processes, equipment, and safety practices.

- Research the specific company you are applying to, including its history, operations, and culture.

2. Practice Common Interview Questions

- Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

3. Highlight Relevant Skills and Experience

- Emphasize your technical skills, such as knowledge of compressors, pumps, and electrical systems.

- Showcase your experience in troubleshooting, repair, and maintenance of industrial equipment.

4. Demonstrate Safety Awareness

- Highlight your understanding of safety protocols and regulations related to compressor station operations.

- Provide examples of your commitment to safety in previous roles.

5. Prepare Questions for the Interviewer

- Prepare thoughtful questions to ask the interviewer about the position, company, and industry.

- This shows your interest and engagement in the interview process.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Compressor Station Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.