Are you gearing up for a career in Compressor Technician? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Compressor Technician and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

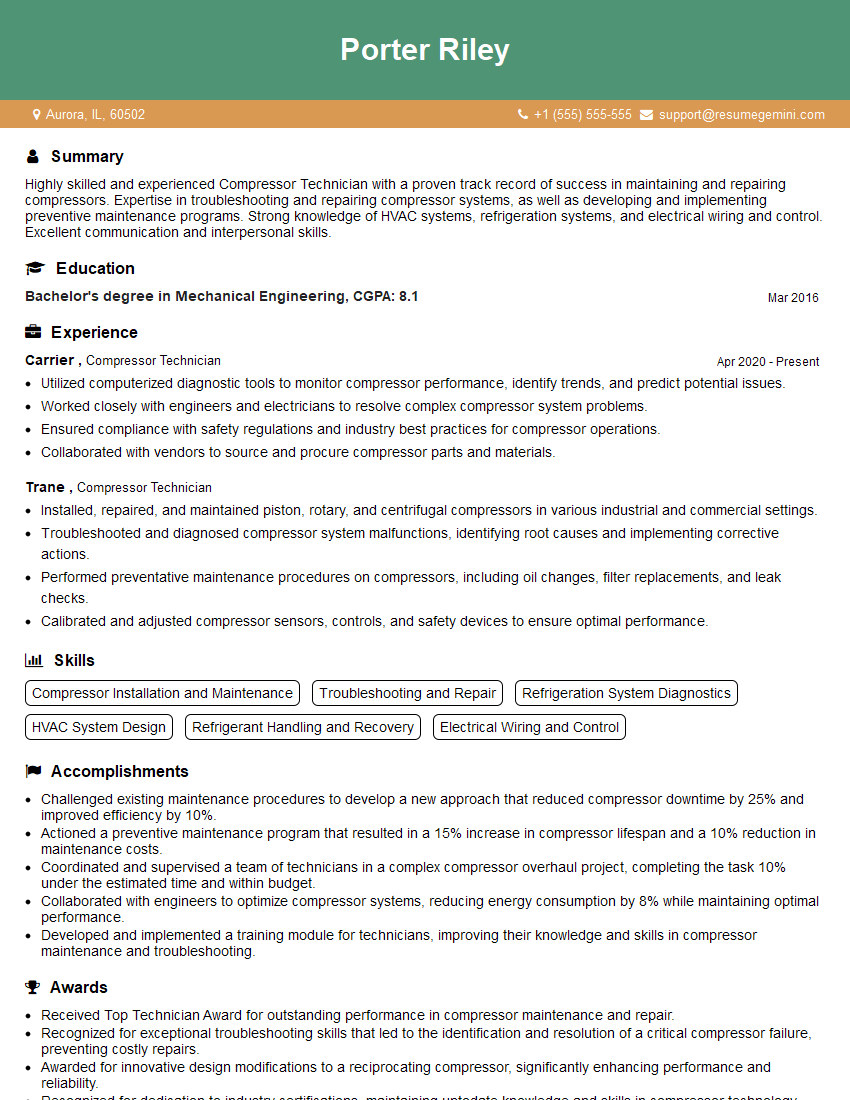

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compressor Technician

1. How do you troubleshoot a compressor that is not starting?

- Check the power supply to the compressor

- Check the fuses or circuit breakers

- Check the start capacitor

- Check the start relay

- Check the motor windings

2. What are the different types of compressors and their applications?

Reciprocating Compressors

- Positive displacement compressors

- Used in refrigeration, air conditioning, and industrial applications

Screw Compressors

- Positive displacement compressors

- Used in industrial applications, such as air compressors and refrigeration systems

Centrifugal Compressors

- Dynamic compressors

- Used in large-scale industrial applications, such as gas turbines and jet engines

3. How do you calculate the efficiency of a compressor?

The efficiency of a compressor is calculated by dividing the actual work done by the compressor by the theoretical work that would be done if the compressor were 100% efficient.

- Efficiency = (Actual work done) / (Theoretical work)

4. What are the common maintenance tasks for a compressor?

- Change the oil and filter

- Inspect and clean the air filter

- Check the belts and pulleys

- Inspect the electrical connections

- Monitor the operating temperature and pressure

5. What are the safety precautions that should be taken when working with compressors?

- Wear appropriate safety gear, including safety glasses, gloves, and ear protection

- Never operate a compressor in a confined space

- Never use a compressor to inflate tires

- Always follow the manufacturer’s instructions for operating the compressor

6. What are the different types of refrigerants used in compressors and their properties?

CFCs (Chlorofluorocarbons)

- No longer used due to their ozone-depleting potential

HCFCs (Hydrochlorofluorocarbons)

- Transitional refrigerants being phased out

HFCs (Hydrofluorocarbons)

- Current generation of refrigerants

- No ozone-depleting potential, but high global warming potential

Natural refrigerants

- Environmentally friendly alternatives to HFCs

- Include ammonia, carbon dioxide, and hydrocarbons

7. How do you diagnose and repair a compressor that is overheating?

- Check the air filter and clean or replace it if necessary

- Check the oil level and add oil if necessary

- Inspect the belts and pulleys for any signs of wear or damage

- Check the electrical connections for any loose or damaged wires

- Monitor the operating temperature and pressure and compare it to the manufacturer’s specifications

8. What are the different types of compressor controls and their functions?

Pressure switches

- Monitor the pressure in the system and turn the compressor on or off as needed

Temperature switches

- Monitor the temperature in the system and turn the compressor on or off as needed

Thermostats

- Control the temperature in a room or space by turning the compressor on or off as needed

Variable speed drives

- Control the speed of the compressor motor to match the load

9. What are the different types of compressor lubrication systems and their advantages and disadvantages?

Splash lubrication

- Oil is splashed onto the moving parts of the compressor

- Advantages: simple and inexpensive

- Disadvantages: not as efficient as other lubrication systems

Pressure lubrication

- Oil is pumped under pressure to the moving parts of the compressor

- Advantages: more efficient than splash lubrication

- Disadvantages: more complex and expensive

Mist lubrication

- Oil is atomized into a mist and then sprayed onto the moving parts of the compressor

- Advantages: very efficient, can be used with high-speed compressors

- Disadvantages: more complex and expensive

10. What are the different types of compressor capacity control methods and their applications?

On/Off control

- The compressor runs at full capacity or is off

- Applications: small compressors, intermittent loads

Stepped capacity control

- The compressor runs at different fixed capacities

- Applications: medium-sized compressors, variable loads

Variable capacity control

- The compressor can run at any capacity between the minimum and maximum

- Applications: large compressors, continuous loads

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compressor Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compressor Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Compressor Technicians play a crucial role in ensuring the smooth operation of industrial and commercial refrigeration systems.

1. Troubleshooting and Repair

Diagnose and troubleshoot malfunctions in refrigeration systems, including compressors, condensers, evaporators, and piping.

- Identify and replace faulty components, such as bearings, seals, and valves.

- Conduct electrical and mechanical tests to pinpoint the root cause of problems.

2. Maintenance and Inspection

Perform routine maintenance tasks to prevent breakdowns and extend equipment life.

- Inspect and clean compressors, filters, and other components.

- Lubricate moving parts and check for leaks.

3. Installation and Commissioning

Install and commission new refrigeration systems, ensuring they meet industry standards.

- Connect and test electrical and mechanical components.

- Conduct performance checks and fine-tune system parameters.

4. Recordkeeping and Documentation

Maintain accurate records of maintenance, repairs, and system performance.

- Prepare reports and log data for analysis.

- Follow established safety and environmental regulations.

Interview Tips

Preparing for a Compressor Technician interview requires a combination of technical knowledge, troubleshooting skills, and a commitment to safety. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Familiarize yourself with the company’s services, products, and industry trends. Understanding the context will help you tailor your answers and demonstrate your enthusiasm for the field.

- Visit the company website and read recent news articles.

- Research industry advancements and best practices.

2. Highlight Your Troubleshooting Abilities

Interviewers will be interested in your ability to diagnose and solve problems efficiently. Share specific examples of how you identified and resolved complex refrigeration malfunctions.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Quantify your accomplishments whenever possible.

3. Showcase Your Mechanical Aptitude

Demonstrate your knowledge of refrigeration systems, including the principles of operation, component functions, and maintenance procedures. Highlight your hands-on experience working with tools and equipment.

- Discuss your understanding of different types of compressors and their applications.

- Explain the refrigeration cycle and how it affects system performance.

4. Emphasize Safety and Compliance

Safety is paramount in refrigeration work. Highlight your commitment to following established safety protocols and industry regulations. Share examples of how you prioritize safety in your daily routine.

- Discuss your knowledge of relevant safety standards and codes.

- Explain how you manage hazardous materials and dispose of them properly.

5. Be Prepared to Discuss Team Dynamics

Compressor Technicians often work as part of a team. Be prepared to discuss your teamwork skills and ability to collaborate with others. Share examples of how you have contributed to successful team projects.

- Explain how you communicate effectively with colleagues and supervisors.

- Highlight your ability to resolve conflicts and foster a positive work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Compressor Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!