Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Computer Engraver interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Computer Engraver so you can tailor your answers to impress potential employers.

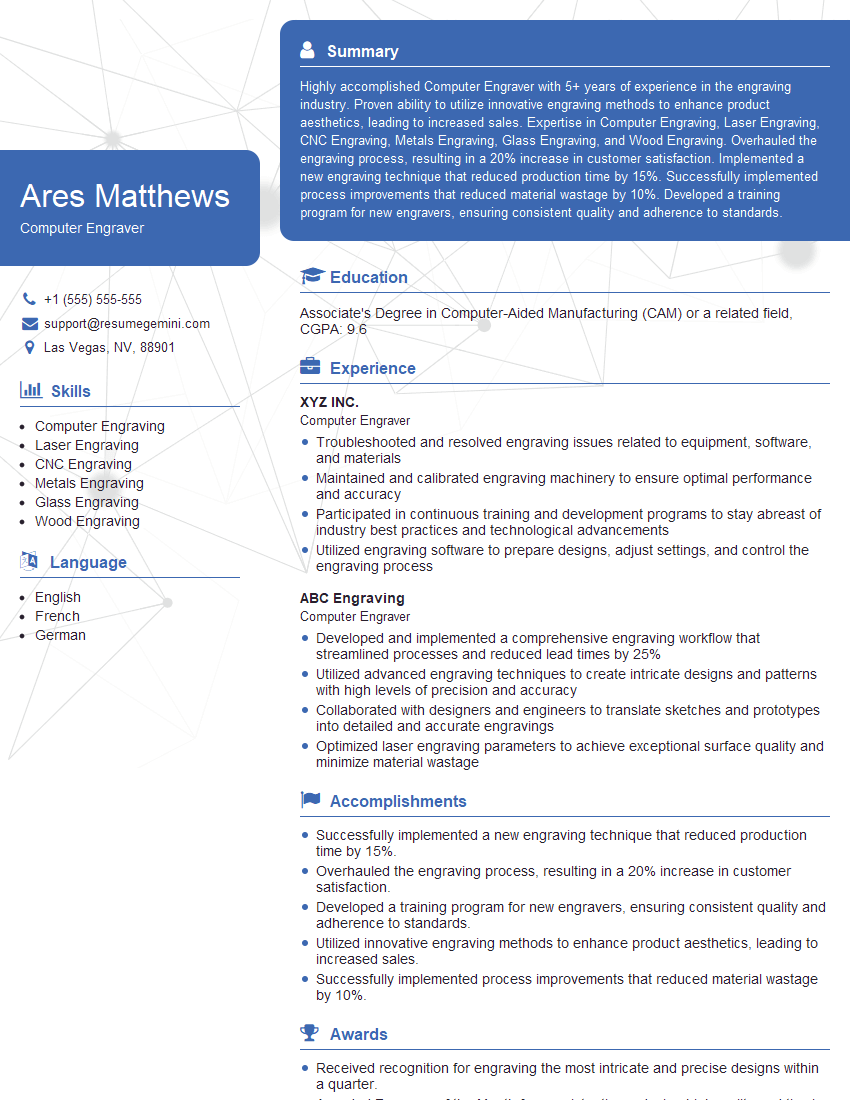

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Computer Engraver

1. What are the different types of engraving machines and their uses?

- Laser Engravers: Use a focused laser beam to vaporize or melt material from the surface, creating precise and intricate designs.

- CNC Engravers: Employ computer-controlled cutting tools to carve designs into various materials, offering high accuracy and repeatability.

- Rotary Engravers: Feature a rotating tool that etches designs onto cylindrical or curved surfaces.

- Impact Engravers: Utilize a vibrating stylus or punch to create indentations, ideal for marking metal tags or jewelry.

- Micro Engravers: Specialized machines designed for precise and delicate engraving on small objects, such as surgical tools or watch components.

2. Describe the process of designing and creating an engraving project.

Creating the Design

- Consult with the client to understand their vision and requirements.

- Create a design using software such as AutoCAD or CorelDRAW.

- Ensure the design meets the technical specifications of the engraving machine.

Preparing the Material

- Select the appropriate material based on the desired finish and durability.

- Prepare the surface by cleaning and smoothing it.

Engraving

- Set up the engraving machine according to the design and material specifications.

- Secure the material in place and start the engraving process.

Finishing

- Remove the engraved material from the machine.

- Clean and polish the engraved surface to enhance its appearance.

3. What are the factors to consider when selecting the appropriate engraving technique?

- Material: Different materials have varying properties that influence the choice of engraving technique.

- Design Complexity: Intricate designs may require specialized techniques or machines.

- Accuracy and Precision: Some techniques provide higher levels of precision than others.

- Speed and Efficiency: Consider the time required to complete the engraving.

- Cost: The cost of the engraving equipment and materials should be taken into account.

4. What are the safety precautions to observe when operating an engraving machine?

- Wear appropriate safety gear: Gloves, safety glasses, and hearing protection.

- Ensure proper ventilation: Engraving processes can release fumes or particles.

- Inspect the machine regularly: Check for any loose connections or damaged parts.

- Follow manufacturer’s instructions: Operate the machine according to the provided guidelines.

- Be aware of potential hazards: Keep hands and hair away from moving parts.

5. How do you ensure the quality and accuracy of your engravings?

- Careful design preparation: Double-checking designs for errors and optimizing them for the chosen technique.

- Proper machine calibration: Ensuring that the engraving machine is set up and calibrated correctly.

- Using high-quality materials: Selecting materials that are suitable for the engraving process and provide the desired finish.

- Diligent attention to detail: Paying close attention to the engraving process and making adjustments as needed.

- Post-engraving inspection: Thoroughly examining the engraved product to ensure it meets the agreed-upon specifications.

6. What are the different materials that can be engraved?

- Metals: Stainless steel, aluminum, brass, copper

- Plastics: Acrylic, polycarbonate, polyethylene

- Wood: Hardwoods, softwoods, plywood

- Glass: Float glass, tempered glass, crystal

- Leather: Natural leather, faux leather

- Stone: Granite, marble, slate

- Ceramics: Tiles, plates, mugs

7. How do you handle complex engraving projects?

- Thorough planning: Breaking down the project into smaller, manageable tasks.

- Using specialized software: Employing CAD/CAM software to create detailed designs and toolpaths.

- Optimizing machine settings: Adjusting engraving parameters to achieve the desired results.

- Regular monitoring: Closely monitoring the engraving process to ensure accuracy and quality.

- Collaboration: Consulting with clients, engineers, or designers to ensure project specifications are met.

8. What are the different types of finishes that can be achieved with engraving?

- Polished: Smooth and reflective finish

- Brushed: Satin-like finish with a fine grain

- Textured: Embossed or debossed finish with patterns or designs

- Etched: Creates shallow and precise lines or images

- Painted: Filling engraved areas with paint for contrast

- Anodized: Electro-chemical process to create colored finishes on metals

- Plated: Coating the engraved surface with a thin layer of metal

9. How do you handle customer revisions or changes to engraving projects?

- Communicating effectively: Clarifying the changes with the customer and discussing their expectations.

- Assessing feasibility: Evaluating whether the revisions are technically possible and within the agreed-upon timeframe.

- Updating the design: Modifying the design as per the customer’s request, ensuring accuracy and compliance with specifications.

- Re-engraving: Making the necessary changes to the engraved product.

- Quality control: Inspecting the revised engraving to ensure it meets the customer’s requirements.

10. How do you stay updated on the latest engraving techniques and technologies?

- Attending industry events and conferences: Networking with other professionals and learning about new technologies.

- Reading industry publications and online resources: Staying informed about the latest developments and advancements.

- Experimentation and research: Exploring new techniques and materials to enhance engraving capabilities.

- Training and certification: Undertaking courses or certifications to gain specialized knowledge and skills.

- Collaboration with suppliers and manufacturers: Partnering with reputable suppliers to access innovative equipment and materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Computer Engraver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Computer Engraver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Computer Engravers are responsible for creating designs and images on various materials using a computer-controlled engraving machine.

1. Design and Artwork Creation

Develop and create original designs or modify existing ones according to client specifications.

- Use design software and industry-specific tools to create precise artwork.

- Ensure designs meet quality standards and production requirements.

2. Machine Operation and Maintenance

Operate and maintain computer-controlled engraving machines to produce intricate designs.

- Set up and calibrate machines according to project requirements.

- Monitor machine operations and adjust settings to achieve optimal results.

3. Material Handling and Preparation

Select and prepare appropriate materials for engraving, ensuring compatibility and quality.

- Inspect materials for defects and determine suitable engraving methods.

- Clean and prepare materials to achieve desired surface finish.

4. Quality Control and Inspection

Inspect engraved products to ensure accuracy, precision, and adherence to specifications.

- Identify and rectify any errors or imperfections in the final product.

- Maintain high standards of quality control to ensure customer satisfaction.

Interview Tips

Preparing for a Computer Engraver interview requires understanding the job responsibilities and presenting your skills and experiences effectively. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Gain insights into the company’s values, products, and industry trends. This demonstrates your interest and enthusiasm for the role.

- Visit the company website and read industry publications.

- Identify key industry players and their latest advancements in engraving techniques.

2. Showcase Your Design and Technical Skills

Emphasize your proficiency in design software, material selection, and engraving machine operation. Provide specific examples of your work.

- Create a portfolio showcasing your best designs and engravings.

- Highlight your knowledge of different engraving techniques and their applications.

3. Highlight Your Attention to Detail and Precision

Computer Engravers require meticulous attention to detail and precision in their work. Showcase your ability to work accurately and meet tight tolerances.

- Share examples where you ensured exceptional accuracy and precision in previous projects.

- Explain your quality control process and how you maintain consistent standards.

4. Demonstrate Your Problem-Solving Abilities

Interviewers may assess your ability to solve problems and handle challenges. Prepare examples of how you overcame obstacles or found innovative solutions in your work.

- Describe situations where you successfully resolved technical issues with engraving machines.

- Explain how you troubleshoot problems and develop creative solutions to meet customer requirements.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Computer Engraver interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!