Are you gearing up for a career in Computer Numerical Control Grinder (CNC Grinder)? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Computer Numerical Control Grinder (CNC Grinder) and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

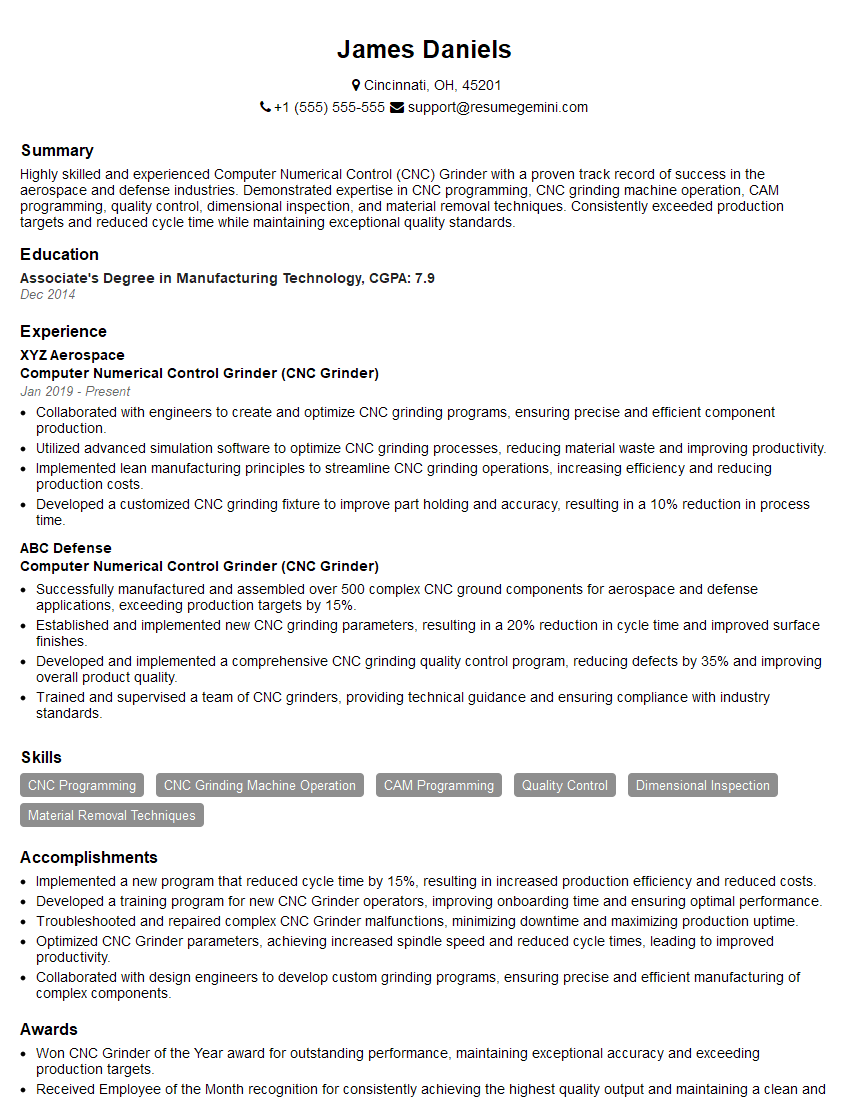

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Computer Numerical Control Grinder (CNC Grinder)

1. What is the difference between a CNC grinder and a conventional grinder?

A CNC grinder is a computer-controlled machine that uses a rotating abrasive wheel to grind metal. A conventional grinder is a manually operated machine that uses a rotating abrasive wheel to grind metal.

- CNC grinders are more accurate and repeatable than conventional grinders.

- CNC grinders can be programmed to perform complex grinding operations.

- CNC grinders are more efficient than conventional grinders.

2. What are the different types of CNC grinders?

- Surface grinders grind flat surfaces.

- Cylindrical grinders grind cylindrical surfaces.

- Internal grinders grind the inside of holes.

- Thread grinders grind threads.

- Centerless grinders grind workpieces that are not held in a chuck.

3. What are the different parts of a CNC grinder?

- Headstock – The headstock holds the workpiece and rotates it during grinding.

- Tailstock – The tailstock supports the workpiece and provides axial force during grinding.

- Table – The table moves the workpiece in the X and Y axes during grinding.

- Saddle – The saddle moves the headstock and tailstock in the Z axis during grinding.

- Grinding wheel – The grinding wheel is the abrasive tool that removes material from the workpiece.

- Coolant system – The coolant system supplies coolant to the grinding wheel and workpiece to prevent overheating.

4. How do you program a CNC grinder?

CNC grinders are programmed using a computer program called a CAM system. The CAM system generates a set of instructions that tell the grinder how to move the workpiece and grinding wheel to produce the desired finish.

- The first step in programming a CNC grinder is to create a CAD model of the workpiece.

- The next step is to import the CAD model into the CAM system.

- The CAM system will then generate a set of instructions that tell the grinder how to move the workpiece and grinding wheel to produce the desired finish.

5. How do you operate a CNC grinder?

To operate a CNC grinder, you must first load the workpiece into the grinder. Once the workpiece is loaded, you must enter the grinding program into the grinder’s control panel. The grinder will then automatically execute the grinding program.

- It is important to monitor the grinding process to ensure that the workpiece is being ground to the desired finish.

- You must also be aware of the safety precautions that must be followed when operating a CNC grinder.

6. What are the different types of grinding wheels?

- Abrasive wheels – Abrasive wheels are made of a hard abrasive material, such as diamond or CBN.

- Bonded wheels – Bonded wheels are made of abrasive particles that are bonded together with a resin or ceramic bond.

- Vitrified wheels – Vitrified wheels are made of abrasive particles that are bonded together with a glass bond.

7. How do you select the correct grinding wheel for a particular grinding operation?

The correct grinding wheel for a particular grinding operation is selected based on the following factors:

- The type of material being ground

- The desired surface finish

- The grinding operation being performed

8. How do you maintain a CNC grinder?

To maintain a CNC grinder, you must perform the following tasks:

- Clean the grinder regularly.

- Lubricate the grinder regularly.

- Inspect the grinder regularly for wear and tear.

- Perform scheduled maintenance on the grinder.

9. What are the safety precautions that must be followed when operating a CNC grinder?

- Wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Keep your hands away from the grinding wheel.

- Do not operate the grinder if it is not properly guarded.

- Be aware of the potential hazards of grinding, such as sparks and flying debris.

10. What are the career prospects for CNC grinders?

CNC grinders are in high demand in a variety of industries, including automotive, aerospace, and manufacturing. CNC grinders with experience and expertise can earn a good salary and benefits.

- The career prospects for CNC grinders are expected to remain strong in the coming years.

- As technology advances, CNC grinders will be able to perform even more complex grinding operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Computer Numerical Control Grinder (CNC Grinder).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Computer Numerical Control Grinder (CNC Grinder)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

CNC Grinders are highly skilled professionals responsible for operating and maintaining Computer Numerical Control (CNC) grinding machines. These machines are used to shape and finish metal parts with precision, and CNC Grinders play a crucial role in ensuring the accuracy and quality of these parts.

1. CNC Machine Operation

CNC Grinders are responsible for programming, setting up, and operating CNC grinding machines. They use computer-aided design (CAD) software to create programs that guide the machine through the grinding process. They also set up the machine with the appropriate tools and materials and ensure that it is operating correctly.

2. Part Inspection and Measurement

CNC Grinders must inspect and measure the finished parts to ensure that they meet the specified tolerances. They use precision measuring tools and equipment to verify the dimensions, surface finish, and other quality characteristics of the parts.

3. Tool Maintenance and Calibration

CNC Grinders are responsible for maintaining and calibrating the tools used in the grinding process. This includes sharpening and replacing grinding wheels, as well as calibrating the machine’s sensors and measuring devices.

4. Troubleshooting and Problem Solving

CNC Grinders must be able to troubleshoot and solve problems that arise during the grinding process. They must be able to identify the source of any issues and take corrective action to ensure that the machine is operating properly and producing quality parts.

Interview Tips

Preparing thoroughly for a CNC Grinder interview is key to increasing your chances of success. Here are some tips to help you ace the interview and land the job.

1. Research the Company and Position

Before the interview, take time to research the company and the specific CNC Grinder position. This will help you understand the company’s culture, values, and business goals. It will also help you tailor your answers to the specific requirements of the job.

2. Practice Your Answers

Prepare answers to common interview questions. Practice answering these questions out loud. This will help you feel more confident and articulate during the interview. Focus on highlighting your skills, experience, and qualifications that are most relevant to the job.

3. Showcase Your Technical Skills

During the interview, be prepared to demonstrate your technical skills and knowledge. This may include questions about CNC programming, machine operation, and quality control. If possible, bring examples of your work or projects that showcase your abilities.

4. Explain Your Problem-Solving Abilities

CNC Grinders need to be able to troubleshoot and solve problems. In the interview, highlight your problem-solving skills. Give examples of how you have identified and resolved issues in the past.

5. Ask Insightful Questions

At the end of the interview, take the opportunity to ask thoughtful questions. This shows that you are engaged and interested in the position. Ask questions about the company, the team, and the future of the industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Computer Numerical Control Grinder (CNC Grinder) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!