Are you gearing up for an interview for a Computer Numerical Control Machining Center Operator (CNC Machining Center Operator) position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Computer Numerical Control Machining Center Operator (CNC Machining Center Operator) and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

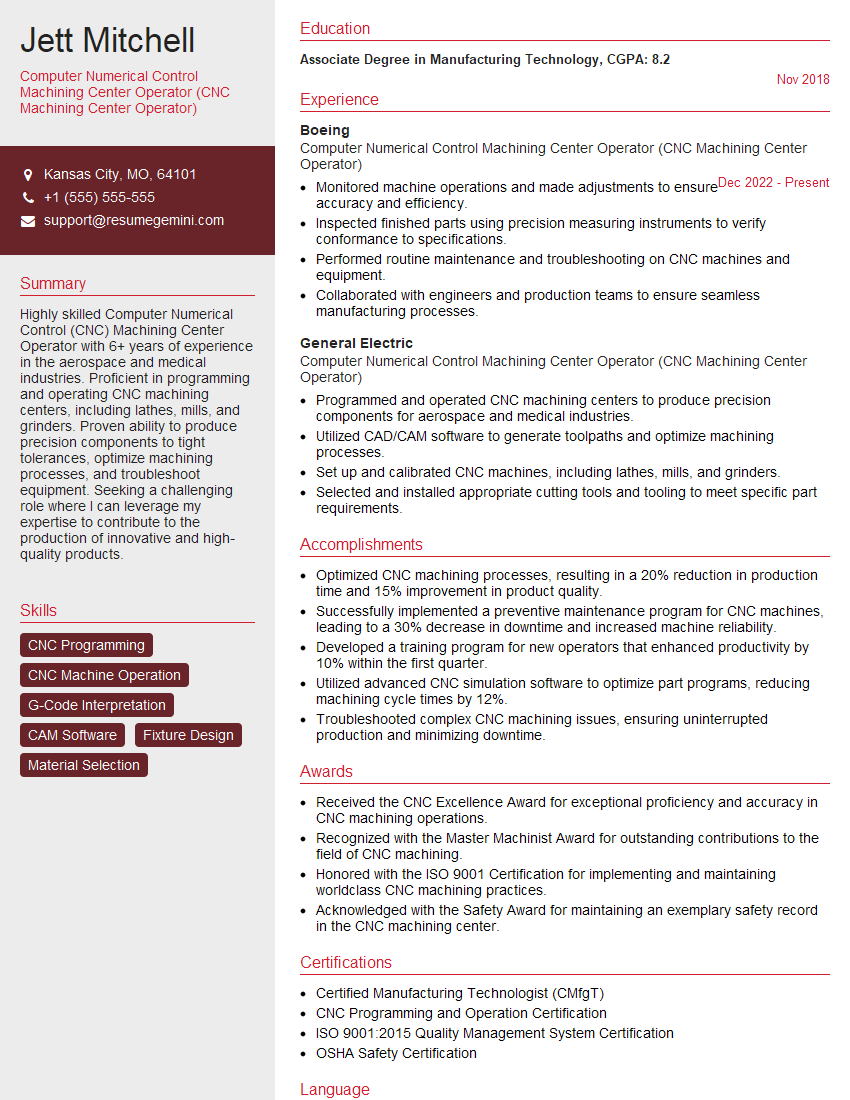

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Computer Numerical Control Machining Center Operator (CNC Machining Center Operator)

1. Describe the process of setting up a CNC machine for a new job.

- Review the job specifications and engineering drawings to determine the required settings and tools.

- Select the appropriate cutting tools and mount them on the machine.

- Set the work offsets and tool offsets to ensure accurate positioning.

- Load the CNC program into the machine and verify its parameters.

- Perform a dry run to check for any errors or collisions.

2. How do you troubleshoot common CNC machine errors?

Error detection

- Observe the machine’s display and error messages.

- Check the program for syntax errors or incorrect parameters.

- Inspect the cutting tools for wear or damage.

Error resolution

- Clear error messages and reset the machine if necessary.

- Replace or adjust worn or damaged tools.

- Modify the CNC program to correct errors or optimize settings.

3. Explain the importance of proper tool selection and maintenance for CNC machining.

- Tool selection:

- Improves machining efficiency, accuracy, and surface finish.

- Reduces wear and tear on the machine and cutting tools.

- Ensures optimal cutting parameters for different materials and operations.

- Tool maintenance:

- Extends tool life and reduces downtime.

- Maintains tool accuracy and prevents tool breakage.

- Reduces the risk of defects or accidents due to tool failure.

4. How do you ensure the accuracy and repeatability of CNC machining operations?

- Machine calibration: Regular calibration ensures precise positioning and movement.

- Tool offset compensation: Accurately compensating for tool wear and thermal expansion.

- Fixturing: Using proper fixtures and workholding devices to secure workpieces.

- Cutting parameter optimization: Selecting optimal cutting speeds, feeds, and depths of cut for each operation.

- In-process inspection: Regularly checking dimensions and surface finish to identify any deviations.

5. Describe the different types of CNC control systems and their capabilities.

- Fanuc: Known for reliability, user-friendliness, and advanced features.

- Siemens: Offers powerful CNC systems with extensive functionality and connectivity.

- Mitsubishi: Provides high-speed and high-precision control systems tailored for demanding applications.

- Heidenhain: Specialized in high-accuracy and high-performance CNC systems for complex geometries.

- Mazak: Offers integrated CNC systems optimized for Mazak machine tools.

6. Explain the difference between absolute and incremental programming in CNC machining.

- Absolute programming: Specifies positions in absolute coordinates relative to the machine’s reference point.

- Incremental programming: Specifies positions in relative coordinates, where each move is defined relative to the previous position.

- Advantages of absolute programming:

- Easier to visualize and program.

- Useful for positioning to specific known locations.

- Advantages of incremental programming:

- More compact and efficient code.

- Useful for repetitive operations or contouring.

7. How do you use G-codes and M-codes in CNC programming?

- G-codes:

- Geometric commands that control the movement and position of the machine.

- Common examples include G00 (rapid movement), G01 (linear interpolation), and G02 (circular interpolation).

- M-codes:

- Miscellaneous commands that control auxiliary functions or machine operations.

- Common examples include M00 (program stop), M03 (spindle start), and M05 (spindle stop).

- Using G-codes and M-codes together allows for complex and precise CNC programming.

8. What are the safety protocols and precautions you follow when operating a CNC machine?

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Keep the work area clean and free of tripping hazards.

- Check the machine for any damage or defects before operating.

- Follow lockout/tagout procedures when performing maintenance or repairs.

- Never attempt to operate the machine while under the influence of alcohol or drugs.

9. How do you handle spindle and tool orientation in multi-axis CNC machining?

- Spindle orientation:

- Use G-codes to control the orientation and rotation of the spindle.

- Allows for access to complex geometries and machining of angled surfaces.

- Tool orientation:

- Use tool compensation to adjust the tool’s position relative to the workpiece.

- Compensates for tool wear, deflections, and misalignments.

- Proper handling of spindle and tool orientation enables precise machining and complex part geometries.

10. Describe your experience with CAM software, such as SolidCAM or MasterCAM.

- CAM software experience:

- Proficiency in using CAD/CAM software for generating toolpaths and simulating CNC operations.

- Experience with specific software packages, such as SolidCAM or MasterCAM.

- Benefits of CAM software:

- Efficient toolpath generation and optimization.

- Simulation of machining processes to verify accuracy and identify potential issues.

- Integration with CNC machines for direct program transfer.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Computer Numerical Control Machining Center Operator (CNC Machining Center Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Computer Numerical Control Machining Center Operator (CNC Machining Center Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Computer Numerical Control (CNC) Machining Center Operator is responsible for operating and maintaining CNC machining centers to produce a variety of metal parts according to specifications. Some of the major tasks and activities include:

1. Machine Operations

Setting up and operating CNC machining centers to perform various machining operations, such as milling, drilling, turning, and grinding, to produce parts

- Loading and unloading workpieces, fixtures, and tooling

- Writing, editing, and modifying CNC programs to control the machining process

2. Machine Maintenance

Performing routine maintenance and repairs on CNC machining centers, including cleaning, lubricating, and replacing parts

- Identifying and troubleshooting machine malfunctions

- Calibrating and adjusting the machine to ensure accuracy and precision

3. Quality Assurance

Inspecting and measuring parts to ensure that they meet specifications

- Using measuring tools and equipment to check dimensions and tolerances

- Identifying and correcting any defects or errors

4. Production Monitoring

Monitoring the machining process and making adjustments as needed to optimize production

- Keeping track of production quantities and quality

- Identifying and resolving production issues

Interview Tips

Preparing for a CNC Machining Center Operator interview can increase your chances of making a positive impression and showcasing your skills and experience. Here are some tips to help you prepare:

1. Research the Company and Position

Take the time to learn about the company’s history, products, and services. This will help you understand their business and the role of the CNC Machining Center Operator within the organization. It also demonstrates your interest in the company and the position.

- Visit the company’s website and social media profiles.

- Read industry news and articles about the company.

- Connect with current or former employees on LinkedIn to gain insights into the company culture and the position.

2. Practice Your Answers

Anticipate common interview questions and practice your answers to articulate your skills and experience effectively. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Describe a situation where you successfully operated a CNC machining center.

- Explain the task you were responsible for and the actions you took.

- Quantify the results of your efforts, such as increased production or improved quality.

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in CNC machining, including your proficiency in operating different types of CNC machines, programming, and maintenance.

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Provide examples of your attention to detail, problem-solving abilities, and commitment to quality.

- Mention any certifications or training you have completed to enhance your skills.

4. Be Enthusiastic and Professional

During the interview, maintain a positive and enthusiastic attitude, and dress professionally. Be respectful, confident, and ask thoughtful questions to demonstrate your interest and engagement.

- Prepare questions about the company’s growth plans, technology roadmap, and opportunities for professional development.

- Express your enthusiasm for the CNC machining field and your eagerness to contribute to the company’s success.

- Follow up after the interview with a thank-you note to reiterate your interest and highlight key points from your conversation.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Computer Numerical Control Machining Center Operator (CNC Machining Center Operator) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!