Are you gearing up for a career in Computer Numerical Control Mill Operator (CNC Mill Operator)? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Computer Numerical Control Mill Operator (CNC Mill Operator) and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

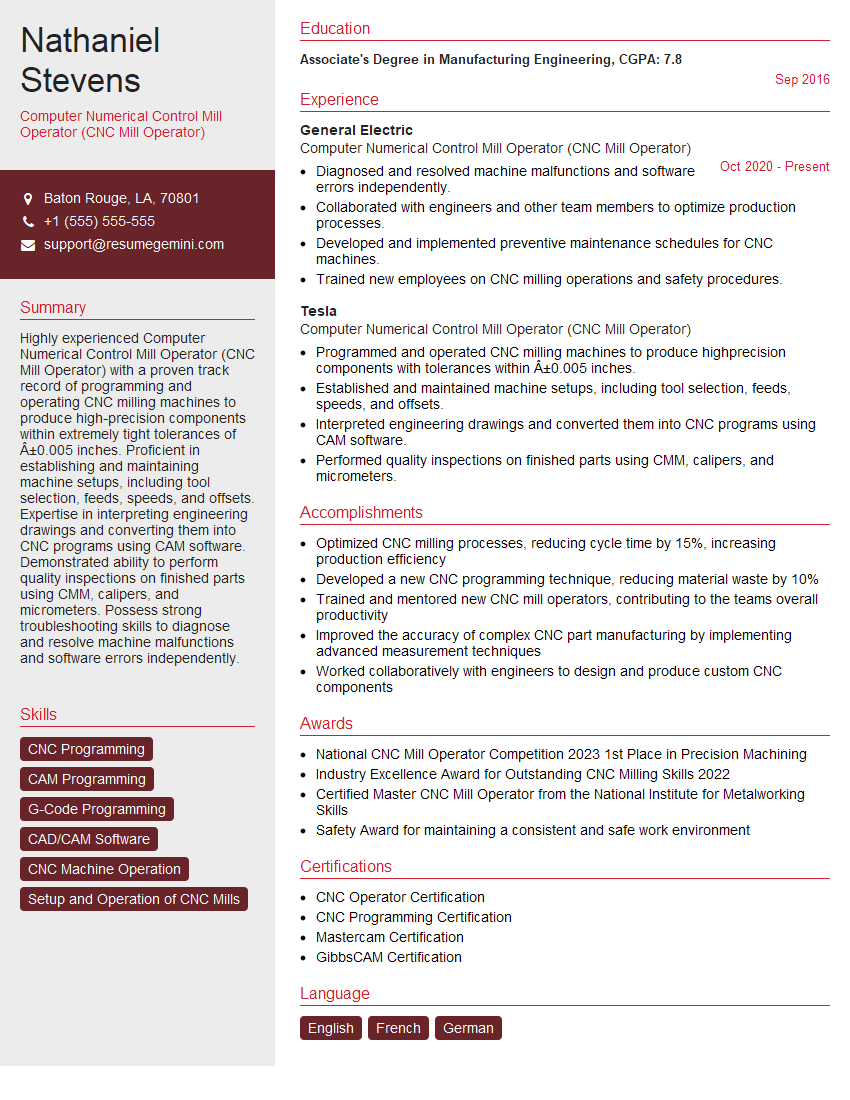

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Computer Numerical Control Mill Operator (CNC Mill Operator)

1. What are the different types of CNC mills?

- Vertical Machining Center (VMC)

- Horizontal Machining Center (HMC)

- Bridgeport-type mill

- Bed-type mill

- Turret mill

2. What are the main components of a CNC mill?

- Machine base and frame

- Table

- Saddle and knee (on VMCs and HMCs)

- Spindle

- Tool changer

- Control system

- Coolant system

3. What are the different types of CNC milling operations?

- Boring

- Drilling

- Facing

- Milling

- Reaming

- Tapping

- Turning

4. What are the different types of CNC milling tools?

- End mills

- Face mills

- Drill bits

- Reaming cutters

- Taps

- Boring bars

5. What is G-code and how is it used in CNC milling?

G-code is a computer programming language used to control the movement of a CNC mill. It is a series of codes that tell the mill where to move, how fast to move, and what cutting tool to use.

6. What are the safety precautions that must be taken when operating a CNC mill?

- Wear appropriate safety gear, including eye protection, hearing protection, and gloves.

- Ensure that the machine is properly grounded.

- Clear the work area of any obstructions.

- Never operate the machine while under the influence of drugs or alcohol.

- Be aware of the location of the emergency stop button.

7. What is the difference between absolute and incremental programming?

- Absolute programming uses the machine’s zero point as the reference point for all movements.

- Incremental programming uses the current position of the machine as the reference point for all movements.

8. What is the difference between a tool offset and a work offset?

- A tool offset is used to compensate for the difference between the actual length of a cutting tool and the length that is programmed in the G-code.

- A work offset is used to compensate for the difference between the actual position of the workpiece and the position that is programmed in the G-code.

9. What is the difference between a roughing pass and a finishing pass?

- A roughing pass is a preliminary cut that removes the majority of the material from the workpiece.

- A finishing pass is a final cut that removes the remaining material and creates the desired surface finish.

10. What is the difference between a conventional CNC mill and a high-speed CNC mill?

- Conventional CNC mills operate at lower speeds and are typically used for heavy-duty cutting applications.

- High-speed CNC mills operate at higher speeds and are typically used for precision cutting applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Computer Numerical Control Mill Operator (CNC Mill Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Computer Numerical Control Mill Operator (CNC Mill Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

CNC Mill Operators are responsible for the operation, programming, and maintenance of Computer Numerical Control (CNC) milling machines. They work closely with engineers and designers to ensure that parts are manufactured according to specifications.

1. Machine Operation

CNC Mill Operators are responsible for the daily operation of CNC milling machines. This includes loading and unloading workpieces, setting up and operating the machine, and monitoring the cutting process.

- Load and unload workpieces from the machine.

- Set up and operate the machine according to the program.

- Monitor the cutting process and make adjustments as needed.

- Inspect finished parts to ensure that they meet specifications.

2. Programming

CNC Mill Operators are also responsible for programming the CNC milling machines. This involves creating a program that tells the machine how to cut the workpiece.

- Create and edit CNC programs using CAM software.

- Verify and test CNC programs before running them on the machine.

- Troubleshoot and correct errors in CNC programs.

3. Maintenance

CNC Mill Operators are also responsible for the maintenance of CNC milling machines. This includes cleaning, lubricating, and adjusting the machine.

- Clean and lubricate the machine according to the manufacturer’s instructions.

- Adjust the machine to ensure that it is operating properly.

- Perform minor repairs on the machine.

- Report any major problems to the supervisor.

4. Quality Control

CNC Mill Operators are responsible for ensuring that parts are manufactured according to specifications. This includes inspecting finished parts and making sure that they meet the required tolerances.

- Inspect finished parts to ensure that they meet specifications.

- Use measuring tools and gauges to verify dimensions.

- Report any non-conforming parts to the supervisor.

Interview Tips

Preparing for a CNC Mill Operator interview can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a CNC Mill Operator.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work at the company, if possible.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Prepare answers to common interview questions.

- Practice your answers with a friend or family member.

- Be prepared to talk about your experience and skills.

3. Be Prepared to Demonstrate Your Skills

In addition to answering questions, you may also be asked to demonstrate your skills. This could involve programming a CNC milling machine or inspecting a finished part. Be prepared to show the interviewer that you have the skills and knowledge necessary to be successful in the position.

- Bring a portfolio of your work, if possible.

- Be prepared to answer questions about your experience and skills.

- Be confident in your abilities.

4. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest, be confident, and be yourself, and you’ll be sure to make a great impression.

- Be honest and genuine.

- Be yourself and let your personality shine through.

- Be confident in your abilities.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Computer Numerical Control Mill Operator (CNC Mill Operator) role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.