Feeling lost in a sea of interview questions? Landed that dream interview for Computer Numerical Control Operator (CNC Operator) but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Computer Numerical Control Operator (CNC Operator) interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

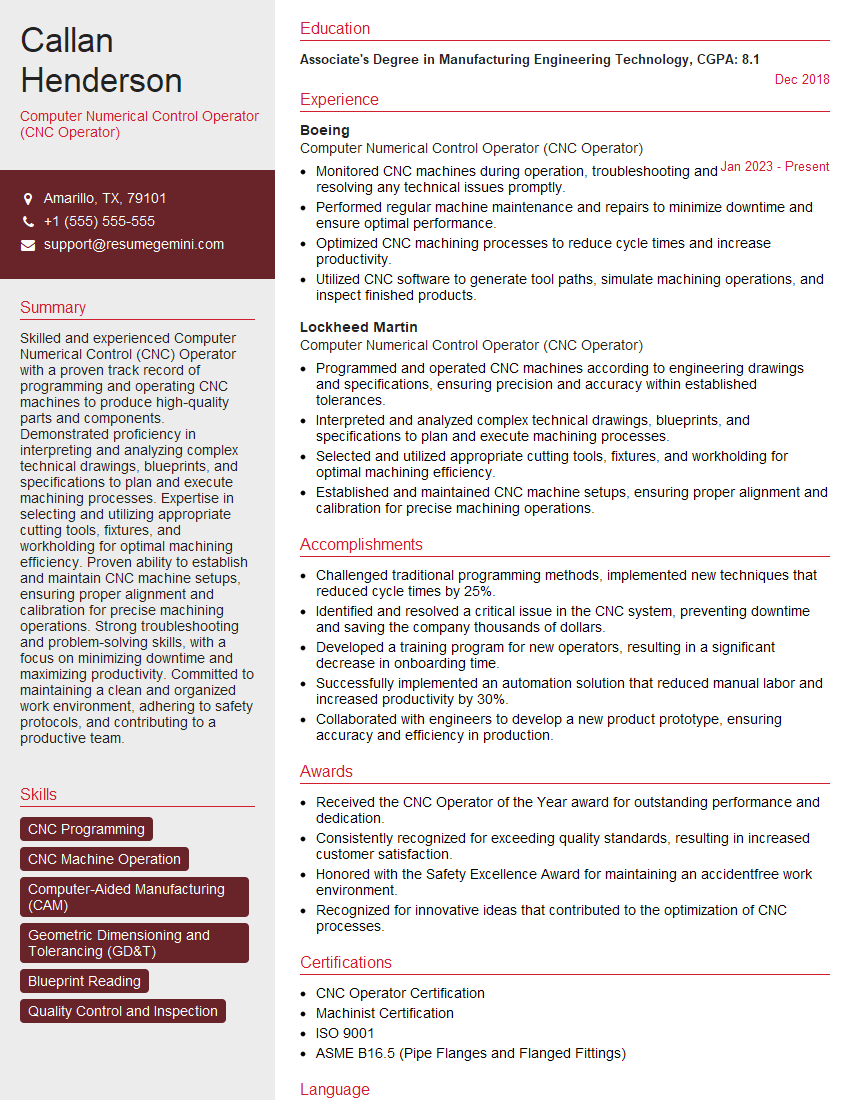

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Computer Numerical Control Operator (CNC Operator)

1. Describe the steps involved in setting up a CNC machine for a new job.

To set up a CNC machine for a new job, I typically follow these steps:

- Review the job specifications and drawings to understand the required dimensions, tolerances, and materials.

- Select the appropriate CNC program for the job and load it into the machine’s control unit.

- Install the necessary tooling and fixtures into the machine’s spindle and table.

- Secure the workpiece in place on the machine’s table using clamps or a vise.

- Set the machine’s operating parameters, such as spindle speed, feed rate, and depth of cut.

- Run a test program to verify that the setup is correct and the machine is operating properly.

2. How do you handle common CNC machine errors, such as tool breakage or workpiece misalignment?

When a CNC machine error occurs, I first identify the type of error and its potential cause.

Troubleshooting

- Tool breakage: Check the tool for damage or wear. Inspect the tool holder for proper tightening. Adjust the spindle speed and feed rate as necessary.

- Workpiece misalignment: Verify that the workpiece is securely clamped and that the machine’s fixtures are properly aligned. Check the CNC program for any errors in workpiece positioning.

Safety

- Ensure that the machine is in a safe state before attempting any repairs.

- Wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

3. Explain the importance of preventative maintenance for CNC machines and describe the key tasks involved.

Preventative maintenance is crucial for maintaining the optimal performance and lifespan of CNC machines. Key tasks include:

- Regular cleaning: Remove chips, dust, and debris from the machine’s components to prevent wear and tear.

- Lubrication: Apply lubricants to moving parts, such as bearings and slides, to reduce friction and extend their life.

- Inspections: Regularly inspect the machine’s components for any signs of wear, damage, or misalignment.

- Calibration: Periodically calibrate the machine’s sensors and axes to ensure accurate positioning and cutting.

- Software updates: Install software updates and patches to keep the machine’s operating system and CNC programs up to date.

4. Describe your experience in using CAM software to generate CNC programs.

I have extensive experience using CAM (Computer-Aided Manufacturing) software to generate CNC programs. I am proficient in various CAM software packages, including Mastercam, SolidCAM, and Fusion 360.

- CAD/CAM integration: I can seamlessly import CAD models into CAM software and generate toolpaths based on the design specifications.

- Toolpath optimization: I optimize toolpaths to achieve efficient cutting, reduce cycle times, and improve surface finish.

- Simulation and verification: I use simulation tools within the CAM software to verify toolpaths and identify potential collisions before running the program on the CNC machine.

5. How do you ensure the quality of parts produced by CNC machines?

I follow a comprehensive quality assurance process:

- Inspection planning: Determine the critical dimensions and features to be inspected based on the job specifications.

- Measurement: Use precision measuring tools, such as calipers, micrometers, and coordinate measuring machines (CMMs), to verify part dimensions.

- Data analysis: Analyze the measurement data to identify any deviations from specifications and determine the root cause of errors.

- Corrective actions: Implement corrective actions to address any quality issues, such as adjusting machine parameters or modifying the CNC program.

- Documentation: Maintain detailed inspection records to track quality trends and identify areas for improvement.

6. Describe your experience in working with different types of CNC machines, such as mills, lathes, and routers.

I have experience operating a wide range of CNC machines, including:

- Mills: 3-axis, 4-axis, and 5-axis mills for machining complex parts with precise tolerances.

- Lathes: CNC lathes for turning, boring, and threading cylindrical workpieces.

- Routers: CNC routers for cutting and shaping materials such as wood, plastics, and composites.

I am familiar with the different capabilities and operating procedures of each type of machine.

7. How do you stay up-to-date with the latest CNC technologies and industry best practices?

- Attend industry events and conferences: Network with other CNC professionals and learn about new technologies and trends.

- Read industry publications and online resources: Stay informed about advancements in CNC machining, software, and tooling.

- Participate in online forums and discussion groups: Engage with experts and share knowledge on CNC-related topics.

- Seek opportunities for professional development: Attend training courses and certifications to enhance my skills and stay current with industry standards.

8. How do you handle the challenges of working in a fast-paced and demanding CNC machining environment?

- Time management: Prioritize tasks effectively and manage my time wisely to meet deadlines without compromising quality.

- Problem-solving: Quickly identify and resolve technical issues with the CNC machine, tooling, or programs to minimize downtime.

- Communication: Clearly communicate with team members, supervisors, and clients to ensure a smooth workflow and address any concerns promptly.

- Continuous improvement: Seek opportunities to improve my skills and knowledge, and suggest process improvements to enhance productivity and efficiency.

9. Describe a project where you successfully used CNC machining to solve a complex manufacturing problem.

In a previous role, I was tasked with creating a custom part for a client with intricate design and tight tolerances.

- Problem analysis: Analyzed the design requirements and identified potential challenges in machining the complex geometry.

- CAM programming: Generated a detailed CNC program using CAM software, optimizing toolpaths and cutting parameters for efficiency and precision.

- Machine setup and operation: Set up the CNC mill, selected the appropriate tooling, and carefully monitored the machining process.

- Inspection and quality control: Used precision measuring tools and CMM to verify the part’s dimensions and surface finish, ensuring it met the client’s specifications.

- Successful delivery: Delivered the completed part to the client on time and within the required quality standards.

10. How would you contribute to our team of CNC operators?

- Technical expertise: Share my knowledge and skills in CNC machining, CAM programming, and quality control.

- Problem-solving: Collaborate with team members to identify and resolve technical challenges, optimizing production efficiency.

- Training and mentoring: Willingly train and assist less experienced operators, fostering a supportive and growth-oriented work environment.

- Innovation: Explore new technologies and process improvements to enhance the team’s capabilities and productivity.

- Safety: Maintain a strong commitment to safety protocols, ensuring a safe and healthy work environment for all.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Computer Numerical Control Operator (CNC Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Computer Numerical Control Operator (CNC Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

CNC Operators are responsible for operating computer-controlled machine tools that create parts and components for a variety of industries, including manufacturing, aerospace, and automotive.

1. Set up and operate CNC machines

Loading work pieces, setting up cutting tools, and entering programming instructions into the machine’s computer

- Using precision measuring instruments to ensure that parts meet specifications

- Monitoring the machine’s operation and making adjustments as needed

2. Maintain CNC machines

Cleaning and lubricating machines, replacing worn parts, and performing routine maintenance

- Conducting regular inspections and troubleshooting any problems that arise

- Maintaining a clean and organized work area

3. Inspect finished parts

Checking dimensions, tolerances, and surface finish to ensure that parts meet specifications

- Reporting any discrepancies to supervisors

- Correcting any errors in the machining process

4. Work in a team environment

Coordinating with other team members to ensure that parts are produced on time and to specifications

- Assisting other team members with their tasks

- Receiving and following instructions from supervisors

Interview Tips

Preparing for a CNC Operator interview can help you make a great impression on the hiring manager and increase your chances of getting the job. Here are a few tips to help you prepare and answering common interview questions.

1. Research the company and the position

Take some time to learn about the company’s history, culture, and products. This will help you understand the company’s needs and how your skills and experience can benefit them.

- Look up the company’s website and social media pages.

- Also, read news articles and industry publications to learn more about the company and the position.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as:

- Tell me about your experience operating CNC machines.

- What are your strengths and weaknesses as a CNC Operator?

- Why are you interested in working for this company?

Take some time to think about how you would answer these questions and practice your answers out loud.

3. Highlight your skills and experience

Make sure to highlight your skills and experience in your resume and cover letter. Be specific about the types of CNC machines you have operated and the industries you have worked in.

- Also, quantify your accomplishments whenever possible to help you stand out from other candidates.

4. Dress professionally and arrive on time

First impressions matter, so make sure to dress professionally for your interview and arrive on time. This will show the hiring manager that you are serious about the position and that you respect their time.

- Plan your outfit ahead of time to help you feel confident and prepared.

- Give yourself extra time to get to the interview to avoid being late due to traffic or other unexpected delays.

Next Step:

Now that you’re armed with the knowledge of Computer Numerical Control Operator (CNC Operator) interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Computer Numerical Control Operator (CNC Operator) positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini