Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Computer Numerical Control Programmer (CNC Programmer) interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Computer Numerical Control Programmer (CNC Programmer) so you can tailor your answers to impress potential employers.

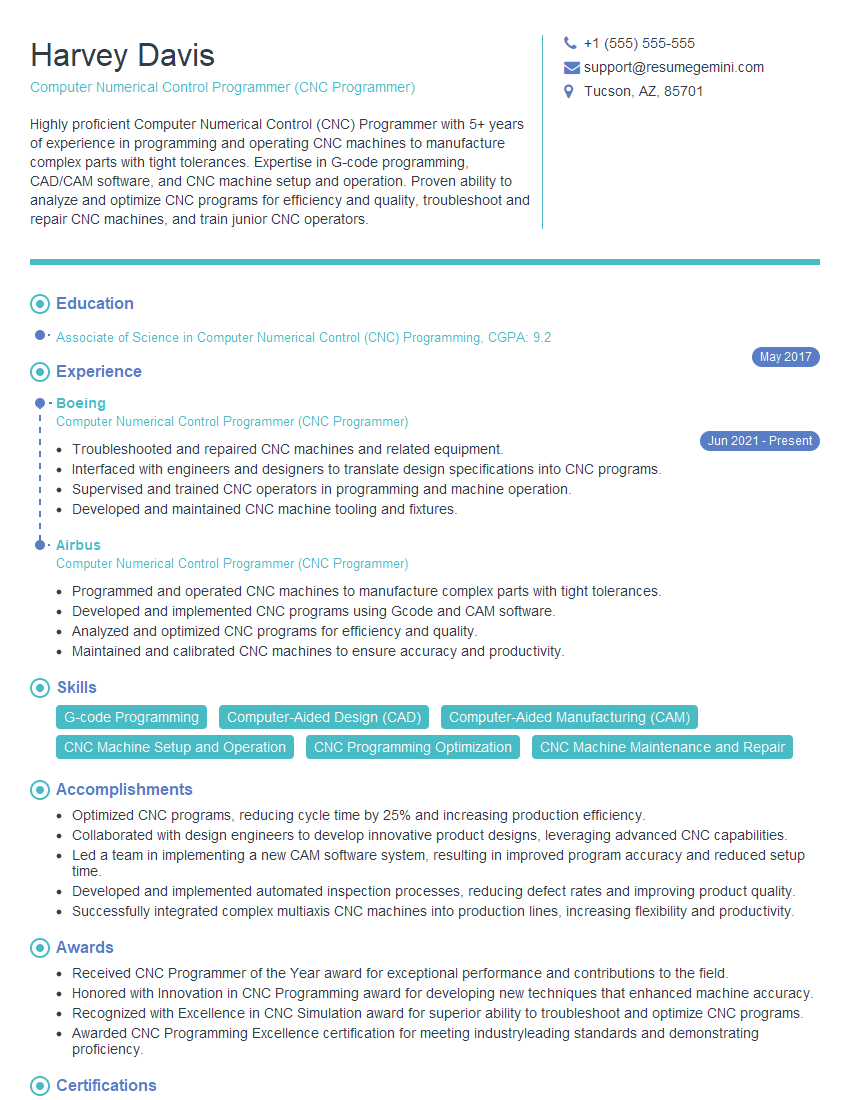

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Computer Numerical Control Programmer (CNC Programmer)

1. What types of CNC machines are you familiar with?

I have experience with a wide range of CNC machines, including:

- 3-axis and 5-axis milling machines

- Lathes

- Plasma cutters

- Wire EDM machines

2. What is G-code?

Purpose of G-code

- Defines the path of the cutting tool

- Controls the speed and feed rate of the machine

- Specifies other parameters, such as coolant flow

Components of G-code

- Address letter (e.g., X, Y, Z)

- Axis value

- Command (e.g., G01, G02)

3. What is the difference between absolute and incremental programming?

Absolute programming defines the position of the cutting tool in relation to the machine’s zero point.

Incremental programming defines the position of the cutting tool in relation to the current position of the tool.

4. What is a toolpath?

A toolpath is a sequence of points that define the path of the cutting tool. It is generated by CAM software based on the CAD model of the part.

5. What are the different types of cutting tools used in CNC machining?

- End mills

- Drills

- Taps

- Boring tools

- Reaming tools

6. What is the importance of fixturing in CNC machining?

- Holds the workpiece securely in place

- Ensures accuracy and precision

- Prevents damage to the workpiece or the machine

7. What are the safety precautions that must be followed when operating a CNC machine?

- Wear appropriate safety gear

- Keep the work area clean and free of debris

- Inspect the machine before each use

- Never operate the machine under the influence of drugs or alcohol

8. How do you troubleshoot common CNC machine problems?

- Check for loose connections

- Inspect the cutting tool for wear or damage

- Check the G-code program for errors

- Calibrate the machine

9. What are the latest trends in CNC machining?

- Additive manufacturing

- Automation

- Cloud-based manufacturing

- Artificial intelligence

10. How do you stay up-to-date on the latest CNC machining technologies?

- Attend industry conferences and trade shows

- Read industry publications

- Take online courses

- Network with other CNC programmers

11. Describe the process of creating a CNC program.

1. Define the workpiece

- Import the CAD model

- Specify the dimensions and tolerances

2. Generate the toolpath

- Select the appropriate cutting tools

- Define the cutting parameters

- Generate the toolpath using CAM software

3. Output the G-code

- Post-process the toolpath to generate the G-code

- Transfer the G-code to the CNC machine

12. Describe the role of CAM software in CNC machining.

- Generates toolpaths for CNC machines

- Simulates the machining process to identify potential problems

- Provides a graphical interface for creating and editing CNC programs

13. Describe the importance of coolant in CNC machining.

- Lubricates the cutting tool and workpiece

- Cools the cutting tool and workpiece

- Removes chips from the cutting area

14. Describe the different types of CNC machine controllers.

- Open-loop controllers

- Closed-loop controllers

- PC-based controllers

15. Describe the advantages and disadvantages of CNC machining.

Advantages

- High accuracy and precision

- Increased productivity

- Reduced labor costs

- Improved quality control

Disadvantages

- High capital costs

- Requires skilled operators

- Can be complex to program

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Computer Numerical Control Programmer (CNC Programmer).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Computer Numerical Control Programmer (CNC Programmer)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Computer Numerical Control (CNC) Programmers play a crucial role in manufacturing by creating and modifying programs that guide CNC machines. These machines precisely control the movements of cutting tools, shaping and fabricating complex parts. The key job responsibilities of a CNC Programmer include:

1. Program Creation and Modification

Creating and modifying CNC programs using software. These programs specify the exact movements and parameters for CNC machines, ensuring precise and efficient operation.

- Understanding and interpreting engineering drawings and specifications.

- Writing and editing G-code programs, which control the machine’s movements and actions.

2. Machine Setup and Optimization

Setting up and optimizing CNC machines by ensuring proper tool selection, workholding, and cutting parameters. This involves:

- Selecting and mounting the appropriate cutting tools.

- Establishing optimal cutting conditions, such as speed, feed, and depth of cut.

- Solving any technical issues or errors that may arise during the CNC process.

3. Quality Control and Inspection

Inspecting and verifying the quality of parts produced by CNC machines to ensure they meet specifications. This involves:

- Using measuring tools and techniques to check part dimensions and tolerances.

- Identifying and correcting any defects or discrepancies in the parts.

- Documenting inspection results and providing feedback for process improvements.

4. Troubleshooting and Maintenance

Troubleshooting and resolving issues with CNC machines and programs to maintain operational efficiency. This involves:

- Diagnosing and repairing machine malfunctions or errors.

- Maintaining and calibrating the CNC machines for accurate and consistent performance.

- Performing preventive maintenance and adhering to established maintenance schedules.

Interview Tips

To ace an interview for a CNC Programmer position, it’s essential to demonstrate a strong understanding of the job responsibilities and showcase your relevant skills and experience. Here are some interview tips and hacks:

1. Research the Company and Role

Thoroughly research the company and the specific CNC Programmer role you’re applying for. Understanding the company’s industry, products, and the requirements of the position will help you tailor your answers and demonstrate your interest.

2. Quantify Your Experience

When describing your experience in CNC programming, use specific examples and quantify your accomplishments whenever possible. For instance, instead of simply saying “I wrote CNC programs,” highlight a project where you improved efficiency by a certain percentage or reduced scrap rates.

3. Prepare Technical Questions

Anticipate technical questions related to CNC programming and be prepared to answer them thoroughly. This may include questions about G-code, machine setup, quality control, or troubleshooting techniques. Showcase your knowledge and understanding of the principles and practices of CNC programming.

4. Demonstrate Problem-Solving Abilities

Interviewers often ask situational questions to assess your problem-solving abilities. Prepare examples of how you handled challenges in previous roles, such as identifying and resolving machine malfunctions or optimizing cutting parameters to improve production efficiency.

5. Show Your Passion for CNC

CNC Programmers play a crucial role in manufacturing, and it’s important to convey your passion for the field. Explain why you’re interested in CNC programming and how your skills and experience make you an ideal candidate for the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Computer Numerical Control Programmer (CNC Programmer) interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.