Feeling lost in a sea of interview questions? Landed that dream interview for Computer Numerical Control Set-Up and Operator (CNC Set-Up and Operator) but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Computer Numerical Control Set-Up and Operator (CNC Set-Up and Operator) interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

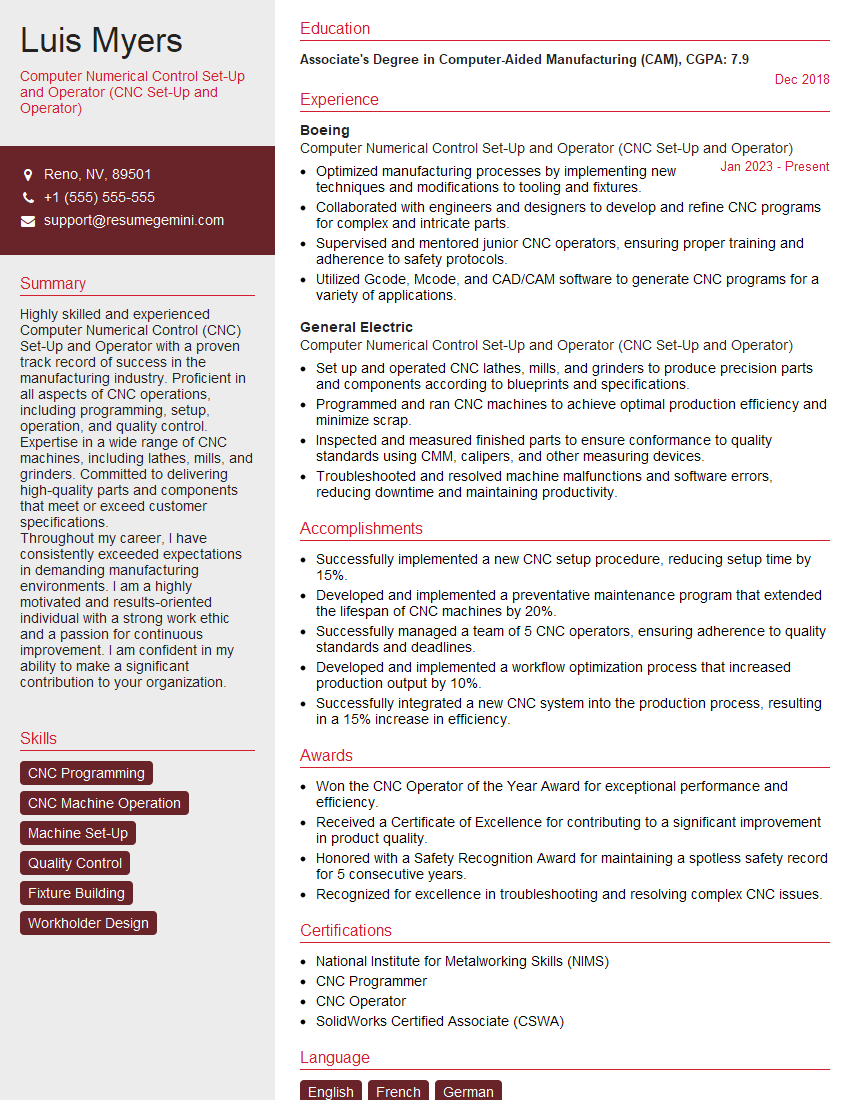

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Computer Numerical Control Set-Up and Operator (CNC Set-Up and Operator)

1. Which parameters would you adjust to improve the surface finish of a CNC-machined part?

To enhance the surface finish of a CNC-machined part, I would optimize the following parameters:

- Cutting Tool Selection: Utilizing sharper and higher-quality cutting tools reduces surface roughness.

- Cutting Speed: Reducing cutting speed allows more time for chip formation and results in a smoother surface.

- Feed Rate: Lower feed rates create a finer surface finish by reducing tool-workpiece interaction.

- Depth of Cut: Taking shallower cuts minimizes material removal per pass, resulting in a smoother surface.

- Toolpath Strategy: Employing toolpaths with smooth transitions and minimal tool deflection reduces surface irregularities.

2. How do you handle tool breakage during CNC machining?

Safety Measures:

- Immediately stop the machine and disconnect power.

- Clear the work area and notify the supervisor.

Assessment and Removal:

- Inspect the tool and spindle for damage.

- Use appropriate tools (e.g., pliers, wrenches) to remove the broken tool safely.

Reprogramming and Resuming Operation:

- Review the program and adjust cutting parameters if necessary.

- Reinsert a new tool and re-zero it precisely.

- Resume machining from the point of interruption.

3. Explain the concepts of G-Code and M-Code in CNC programming.

G-Codes (Geometric Codes):

- Control the movement of the CNC machine, including linear and circular motions.

- Examples: G00 (rapid motion), G01 (linear interpolation), G02/G03 (circular interpolation).

M-Codes (Miscellaneous Codes):

- Control various machine functions, including spindle control, coolant flow, and tool changes.

- Examples: M03 (spindle clockwise), M06 (tool change), M08 (coolant on).

4. How do you ensure accuracy and precision in CNC machining?

- Machine Calibration: Regularly calibrate the CNC machine to maintain precision.

- Tool Inspection and Measurement: Inspect and measure cutting tools to ensure they meet specifications.

- Material Preparation: Properly secure and prepare the workpiece to minimize vibrations.

- G-Code Optimization: Optimize G-Code programs by reviewing toolpaths and selecting appropriate cutting parameters.

- Process Monitoring: Monitor the machining process and make adjustments as needed to maintain accuracy.

5. Describe the different types of CNC controls and their applications.

- Manual Control: Allows the operator to manually move the machine axes and execute commands.

- Computer Numerical Control (CNC): Uses a computer to control machine movements based on a pre-programmed G-Code.

- Direct Numerical Control (DNC): Stores and retrieves CNC programs from a central computer.

- Distributed Numerical Control (DNC): Distributes CNC programs to multiple machines in a network.

- Adaptive Control: Adjusts machine parameters based on real-time sensor data to optimize performance.

6. How do you troubleshoot common CNC machining problems?

- Mechanical Problems: Check for loose connections, worn parts, or lubrication issues.

- Electrical Problems: Inspect wiring, fuses, and electrical components for faults.

- Software Problems: Review G-Code programs for errors, and check for software updates.

- Tooling Problems: Examine cutting tools for damage, wear, or improper setup.

- Material Problems: Verify that the workpiece material meets specifications and is properly secured.

7. Explain the role of CAM software in CNC machining.

CAM (Computer-Aided Manufacturing) software:

- Converts CAD models into G-Code programs for CNC machines.

- Optimizes toolpaths to minimize machining time and improve surface finish.

- Simulates machining operations to verify tool movements and identify potential collisions.

- Provides tool libraries and cutting parameter databases for efficient programming.

8. How do you stay updated with the latest advancements in CNC technology?

- Attend Industry Conferences and Workshops: Participate in events to learn about new trends and best practices.

- Read Technical Journals and Publications: Stay informed about recent developments in CNC machinery and software.

- Join Online Communities and Forums: Engage with other CNC professionals to share knowledge and discuss industry trends.

- Training and Certification Programs: Enrol in courses to enhance skills and gain certifications.

9. How do you ensure safety while working with CNC machines?

- Wear Proper Safety Gear: Always wear protective clothing, safety glasses, and hearing protection.

- Follow Operating Procedures: Adhere to established safety guidelines and machine instructions.

- Inspect Equipment Regularly: Check CNC machines and tools for any potential hazards before operation.

- Be Aware of Machine Movements: Stay clear of moving machine parts and avoid reaching into the work area.

- Use Proper Lockout/Tagout Procedures: Isolate machines from power sources during maintenance or repairs.

10. What are the key performance indicators (KPIs) you track to measure your productivity as a CNC Set-Up and Operator?

- Production Output: Number of parts produced within a specified time frame.

- Machine Utilization: Percentage of time the CNC machine is actively cutting material.

- Setup Time: Time spent configuring the machine and preparing for production.

- Cycle Time: Time taken to complete a single machining cycle.

- Defect Rate: Percentage of parts that do not meet quality standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Computer Numerical Control Set-Up and Operator (CNC Set-Up and Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Computer Numerical Control Set-Up and Operator (CNC Set-Up and Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

CNC Set-Up and Operators play a crucial role in ensuring the efficient operation of CNC (Computer Numerical Control) machines, ensuring precision and accuracy in the production process.

1. Machine Set-Up and Operation

Set up, operate, and monitor CNC machines according to engineering specifications and blueprints.

- Configure and program CNC machines using CAM (Computer-Aided Manufacturing) software and G-codes.

- Oversee the production process, monitor tool performance, and make necessary adjustments to optimize operations.

2. Inspection and Quality Control

Conduct periodic inspections to ensure that the produced parts meet quality standards and specifications.

- Use measuring instruments and gauges to verify dimensions, tolerances, and surface finishes.

- Identify and rectify any deviations from specifications, ensuring the quality of the output.

3. Maintenance and Troubleshooting

Maintain and troubleshoot CNC machines to ensure optimal performance and prevent downtime.

- Perform regular maintenance tasks, such as lubrication, cleaning, and tool replacement.

- Identify and resolve machine malfunctions, addressing issues such as software errors, mechanical failures, and tool wear.

4. Safety Compliance

Adhere to safety regulations and protocols to ensure a safe work environment.

- Wear appropriate personal protective equipment (PPE) and follow established safety procedures.

- Maintain a clean and organized workspace to prevent accidents and hazards.

Interview Tips

Aceing a CNC Set-Up and Operator interview requires thorough preparation and showcasing your skills and experience.

1. Research the Company and Position

Familiarize yourself with the company, its industry, and the specific role you are applying for.

- Visit the company’s website to learn about their products, services, and culture.

- Study the job description carefully to understand the key responsibilities and qualifications.

2. Highlight Your Technical Skills

Showcase your proficiency in CNC programming, CAM software, and G-codes.

- Provide specific examples of projects where you successfully programmed and operated CNC machines.

- Discuss your knowledge of different CNC machine types and the materials they can work with.

3. Emphasize Inspection and Quality Control

Highlight your attention to detail and ability to ensure product quality.

- Describe your experience using measuring tools and gauges to verify dimensions and tolerances.

- Explain how you identify and resolve quality deviations, ensuring the production of high-quality parts.

4. Demonstrate Troubleshooting Abilities

Showcase your problem-solving skills and ability to troubleshoot CNC machines.

- Provide examples of troubleshooting experiences where you identified and resolved machine malfunctions.

- Explain your approach to diagnosing issues, considering software errors, mechanical failures, and tool wear.

5. Stress Safety Compliance

Emphasize your commitment to safety and adherence to established protocols.

- Describe your experience in wearing PPE, following safety procedures, and maintaining a clean work environment.

- Explain how you prioritize safety in your work to prevent accidents and ensure a safe work environment.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Computer Numerical Control Set-Up and Operator (CNC Set-Up and Operator), it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Computer Numerical Control Set-Up and Operator (CNC Set-Up and Operator) positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.