Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Computer Numerical Control Turning Machine Operator (CNC Turning Machine Operator) interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Computer Numerical Control Turning Machine Operator (CNC Turning Machine Operator) so you can tailor your answers to impress potential employers.

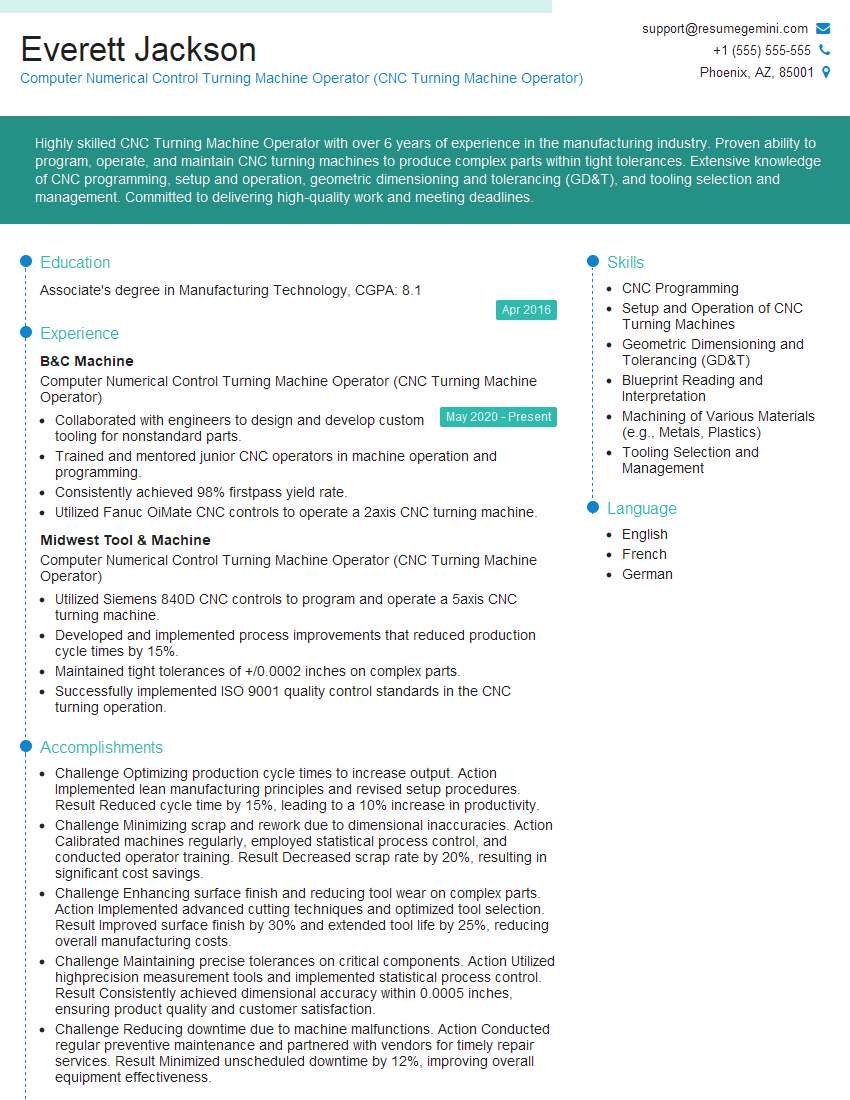

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Computer Numerical Control Turning Machine Operator (CNC Turning Machine Operator)

1. What is G-code and M-code?

G-code is a programming language used to control the movement of CNC machines. It is used to define the path of the cutting tool, the speed of the machine, and other parameters. M-code is used to control the auxiliary functions of the machine, such as coolant, spindle speed, and tool changes.

2. What are the different types of CNC turning machines?

There are two main types of CNC turning machines: vertical and horizontal. Vertical turning machines have the spindle mounted vertically, while horizontal turning machines have the spindle mounted horizontally.

3. What are the different types of cutting tools used in CNC turning?

There are many different types of cutting tools used in CNC turning, including carbide inserts, high-speed steel tools, and diamond tools. The type of cutting tool used depends on the material being cut, the desired surface finish, and the cutting speed.

4. What are the safety procedures that must be followed when operating a CNC turning machine?

There are many safety procedures that must be followed when operating a CNC turning machine, including wearing appropriate safety gear, keeping the machine area clean and free of debris, and never reaching into the machine while it is running.

5. What is the difference between absolute and incremental programming?

Absolute programming uses absolute coordinates to define the position of the cutting tool. Incremental programming uses relative coordinates to define the position of the cutting tool. Absolute programming is easier to use, but incremental programming can be more efficient in some cases.

6. What is tool wear compensation?

Tool wear compensation is a feature of CNC turning machines that allows the machine to automatically adjust the cutting tool position to compensate for wear. This helps to maintain the accuracy of the machined parts.

7. What is a collet?

A collet is a device used to hold the workpiece in place on a CNC turning machine. Collets are available in a variety of sizes and shapes to accommodate different workpiece sizes.

8. What is a chuck?

A chuck is a device used to hold the cutting tool in place on a CNC turning machine. Chucks are available in a variety of sizes and shapes to accommodate different cutting tool sizes.

9. What is a tailstock?

A tailstock is a device used to support the workpiece on a CNC turning machine. The tailstock can be moved along the bed of the machine to support workpieces of different lengths.

10. What is a cross-slide?

A cross-slide is a device used to move the cutting tool across the bed of a CNC turning machine. The cross-slide can be moved in both the X and Z axes to position the cutting tool.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Computer Numerical Control Turning Machine Operator (CNC Turning Machine Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Computer Numerical Control Turning Machine Operator (CNC Turning Machine Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Computer Numerical Control (CNC) Turning Machine Operators are responsible for operating CNC turning machines to produce precision-machined parts.

1. Preparing and Setting Up Machines

CNC Turning Machine Operators adjust and secure cutting tools and ensure that they are sharp and ready for use.

- Loading and unloading raw materials like metal rods or bars into the CNC turning machine’s chuck or collet.

- Selecting and installing the appropriate cutting tools based on the job requirements.

- Setting up machine parameters, such as speeds, feeds, and tool offsets, according to the programmed instructions.

- Performing test runs to verify the accuracy and quality of the parts being produced.

2. Monitoring and Operating Machines

CNC Turning Machine Operators oversee the CNC turning machines during operation, ensuring that they run smoothly and produce quality parts.

- Monitoring the machine’s gauges, displays, and sensors to ensure that it is operating within specified tolerances.

- Adjusting cutting parameters as needed to maintain optimal performance and part quality.

- Inspecting finished parts to verify their dimensions, surface finish, and other quality criteria.

- Performing routine maintenance checks and cleaning to keep the machine in good working condition.

3. Programming and Troubleshooting

CNC Turning Machine Operators may also be involved in programming the CNC turning machines and troubleshooting any issues that arise.

- Understanding and interpreting CNC programs written in G-code or other programming languages.

- Making modifications to CNC programs as required to optimize performance or correct errors.

- Diagnosing and resolving machine malfunctions, such as tool breakage, coolant leaks, or software glitches.

- Collaborating with engineers or supervisors to identify and implement process improvements.

4. Maintaining a Safe Work Environment

CNC Turning Machine Operators are responsible for adhering to safety protocols and maintaining a clean and organized work environment.

- Following all established safety procedures, including wearing appropriate personal protective equipment (PPE).

- Keeping the work area clean and free of debris, tools, and materials.

- Reporting any safety hazards or potential issues to their supervisor immediately.

- Complying with all applicable environmental regulations.

Interview Tips

Preparing for a CNC Turning Machine Operator interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company’s history, products or services, and industry standing. This will demonstrate your interest in the position and show that you’ve invested time in the application process.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on trends and developments.

- Check out the company’s recent financial reports to gain insights into their performance and stability.

2. Practice Your Answers to Common Interview Questions

There are certain questions that you’re likely to encounter in a CNC Turning Machine Operator interview. Prepare your answers to these questions in advance to ensure that you can articulate your skills and experience effectively.

- Tell me about your experience operating CNC turning machines.

- What are the key steps involved in programming a CNC turning machine?

- How do you troubleshoot common problems that can occur during CNC turning operations?

3. Highlight Your Skills and Experience

Make sure to highlight your relevant skills and experience in your resume and during the interview. Quantify your accomplishments whenever possible to demonstrate the impact of your work. For example, instead of saying “I operated CNC turning machines,” you could say “I operated CNC turning machines to produce precision-machined parts with tolerances of ±0.005 inches, resulting in a 15% reduction in scrap rate.”.

- Emphasize your proficiency in operating different types of CNC turning machines.

- Highlight your experience in programming and troubleshooting CNC turning machines.

- Showcase your ability to work independently and as part of a team.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role. Here are some examples of good questions to ask:

- What are the company’s growth plans for the future?

- What are the biggest challenges facing the CNC turning industry today?

- What opportunities are there for professional development and advancement within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Computer Numerical Control Turning Machine Operator (CNC Turning Machine Operator) interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.