Are you gearing up for a career in Computer Numerically Controlled Shot Peening Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Computer Numerically Controlled Shot Peening Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

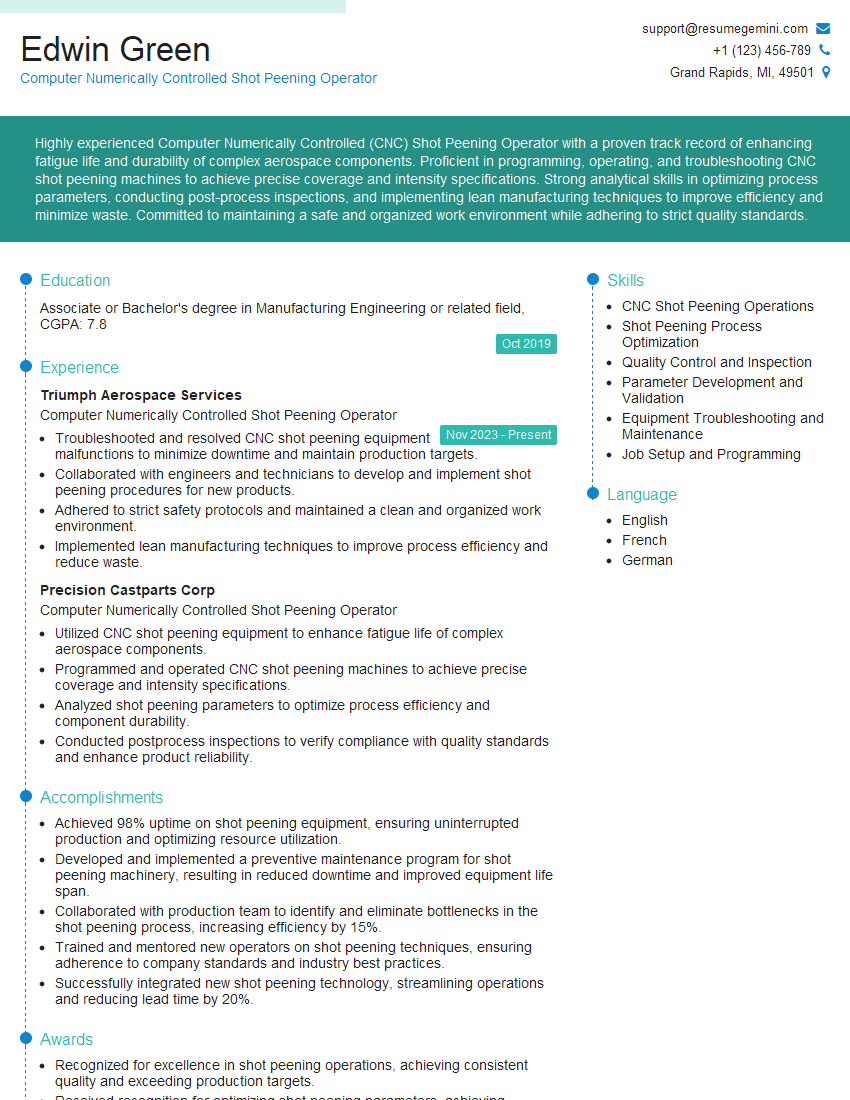

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Computer Numerically Controlled Shot Peening Operator

1. Describe the basic principle of shot peening and its benefits?

Shot peening is a metalworking process that involves impacting a metal surface with small spherical beads (called shot) at high velocity. This process creates tiny indentations on the surface, which can improve the fatigue strength, wear resistance, and corrosion resistance of the metal.

- Increases fatigue strength by introducing compressive residual stresses into the surface.

- Enhances wear resistance by creating a hardened surface layer.

- Improves corrosion resistance by sealing surface cracks and pores.

2. Explain the role of each component in a Computer Numerically Controlled (CNC) shot peening machine?

CNC Control System

- Controls the movement of the shot peening nozzle.

- Determines the shot peening parameters (intensity, coverage, etc.).

Shot Peening Nozzle

- Directs the shot stream onto the target surface.

- Can be adjusted for different shot sizes and intensities.

Shot Peening Media

- Spherical beads made of various materials (e.g., steel, ceramic).

- Selected based on the desired surface finish and properties.

3. How do you determine the appropriate shot peening parameters for a given application?

The appropriate shot peening parameters depend on the material, geometry, and desired outcome of the application. Factors to consider include:

- Shot size and material

- Shot intensity (force applied by the shot)

- Coverage (percentage of surface area peened)

- Time and pattern of peening

4. Describe the quality control procedures involved in shot peening?

- Visual inspection of the peened surface for uniform coverage and no defects.

- Hardness testing to verify the desired surface hardness.

- Residual stress measurement to ensure the introduction of compressive stresses.

- Fatigue testing to assess the improvement in fatigue life.

5. How do you troubleshoot common problems that may arise during CNC shot peening?

- Incorrect shot peening parameters (adjust parameters based on application requirements).

- Clogged shot peening nozzle (clean or replace the nozzle).

- Insufficient shot flow (check shot supply and refill if necessary).

- CNC control system errors (refer to manufacturer’s manuals for troubleshooting).

6. What safety precautions should be followed when operating a CNC shot peening machine?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Ensure the machine is properly grounded and secured.

- Keep the work area clean and free of debris.

- Never operate the machine without proper training and authorization.

7. Describe your experience in programming and operating CNC shot peening machines?

I have extensive experience in programming and operating CNC shot peening machines, including [machine models]. I am proficient in setting up and optimizing shot peening parameters to achieve the desired surface properties. I also have experience in troubleshooting common machine problems and implementing quality control procedures.

8. How do you stay up-to-date on the latest advancements in CNC shot peening technology?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Consult with equipment manufacturers and industry experts.

- Participate in online forums and discussion groups.

9. What are the challenges and rewards of working as a CNC Shot Peening Operator?

Challenges

- Ensuring consistent and high-quality shot peening results.

- Keeping up with the latest technological advancements.

- Working in a potentially hazardous environment.

Rewards

- Playing a crucial role in improving the performance and durability of components.

- Utilizing advanced technology and equipment.

- Contributing to the success of manufacturing operations.

10. Why are you interested in this CNC Shot Peening Operator position?

I am eager to contribute my skills and experience to your organization. I am confident that I can effectively operate and maintain your CNC shot peening machines, ensuring the quality and efficiency of your operations. I am also excited about the opportunity to learn and grow as a professional in this field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Computer Numerically Controlled Shot Peening Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Computer Numerically Controlled Shot Peening Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Computer Numerically Controlled (CNC) Shot Peening Operators are responsible for operating and maintaining CNC shot peening machines, which are used to strengthen and improve the durability of metal components. They work closely with engineers and technicians to develop and implement shot peening processes, and they must have a strong understanding of the principles of shot peening and the effects it has on metal properties.

1. Machine Operation

CNC Shot Peening Operators are responsible for the safe and efficient operation of CNC shot peening machines. They must be able to load and unload parts, set up and adjust the machine, and monitor the process to ensure that it is running properly. They must also be able to troubleshoot and repair any problems that may arise with the machine.

- Load and unload parts from the machine.

- Set up and adjust the machine according to the specifications.

- Monitor the process to ensure that it is running properly.

- Troubleshoot and repair any problems that may arise with the machine.

2. Process Development

CNC Shot Peening Operators work closely with engineers and technicians to develop and implement shot peening processes. They must be able to understand the principles of shot peening and the effects it has on metal properties. They must also be able to develop and implement new processes to meet the specific needs of the customer.

- Understand the principles of shot peening and the effects it has on metal properties.

- Develop and implement new processes to meet the specific needs of the customer.

- Work closely with engineers and technicians to develop and implement shot peening processes.

3. Quality Control

CNC Shot Peening Operators are responsible for ensuring that the parts they produce meet the required quality standards. They must be able to inspect parts for defects and ensure that they are properly finished. They must also be able to maintain records and documentation to prove that the parts meet the required standards.

- Inspect parts for defects.

- Ensure that parts are properly finished.

- Maintain records and documentation to prove that the parts meet the required standards.

4. Safety

CNC Shot Peening Operators must be able to work in a safe and efficient manner. They must be aware of the hazards associated with shot peening and must take the necessary precautions to avoid injury. They must also be able to follow all safety procedures and regulations.

- Be aware of the hazards associated with shot peening.

- Take the necessary precautions to avoid injury.

- Follow all safety procedures and regulations.

Interview Tips

Preparing for an interview for a Computer Numerically Controlled (CNC) Shot Peening Operator position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the company and the position

Before you go on an interview, it is important to do your research on the company and the position you are applying for. This will help you to understand the company’s culture, values, and goals, and it will also help you to tailor your answers to the specific requirements of the position.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work at the company, if possible.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” By practicing your answers to these questions ahead of time, you can ensure that you are able to deliver them confidently and effectively.

- Write down your answers to common interview questions.

- Practice your answers out loud.

- Ask a friend or family member to give you feedback on your answers.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills, so be prepared to talk about them in detail. Be sure to highlight your most relevant experience and skills, and be able to provide specific examples of how you have used them in the past.

- Make a list of your most relevant experience and skills.

- Prepare specific examples of how you have used your experience and skills in the past.

- Be able to articulate how your experience and skills make you the right person for the position.

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic and positive about the position. Be sure to convey your excitement about the opportunity and your desire to join the team.

- Smile and make eye contact with the interviewer.

- Be enthusiastic about the position and the company.

- Show the interviewer that you are eager to learn and grow.

Next Step:

Now that you’re armed with the knowledge of Computer Numerically Controlled Shot Peening Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Computer Numerically Controlled Shot Peening Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini