Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Computerized Mill Recorder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

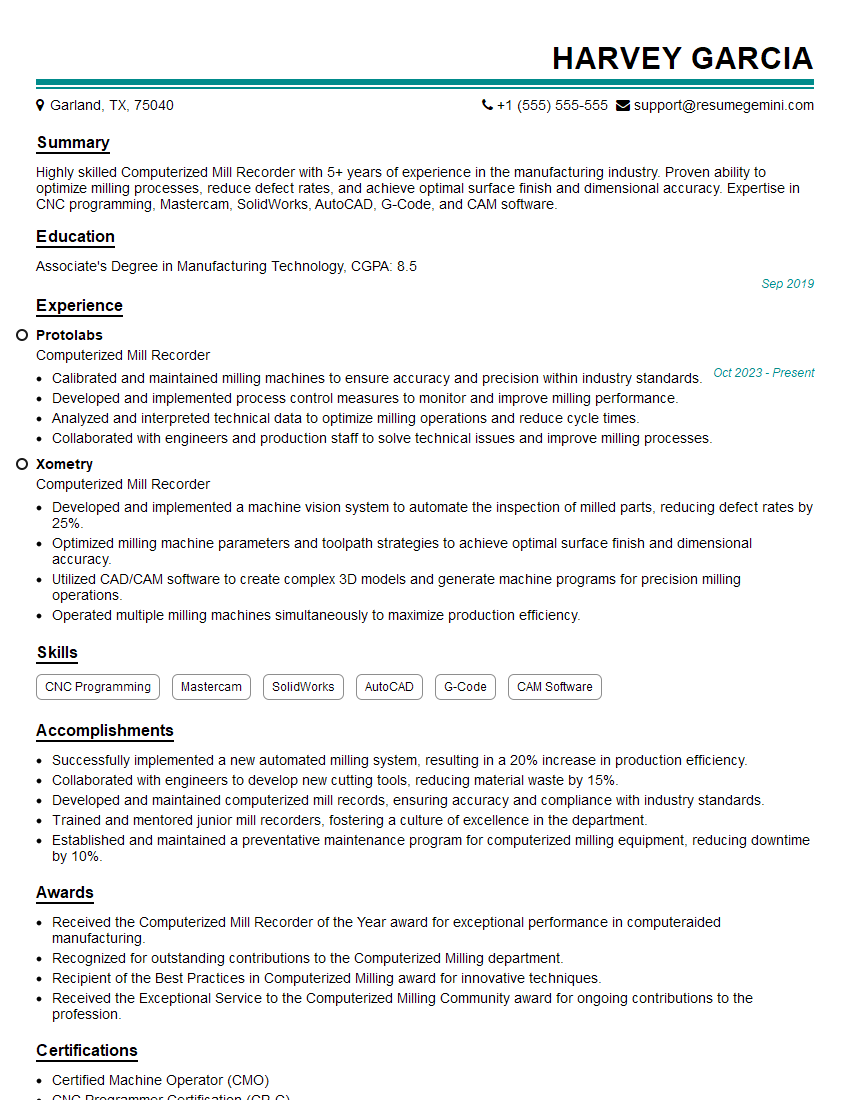

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Computerized Mill Recorder

1. Can you explain the role and responsibilities of a Computerized Mill Recorder?

As a Computerized Mill Recorder, my key responsibilities include:

- Operating and monitoring computerized numerically controlled (CNC) milling machines

- Interpreting blueprints and technical drawings to determine milling parameters

- Setting up and adjusting cutting tools, fixtures, and workpieces

- Monitoring milling processes to ensure precision and quality

- Inspecting finished products and maintaining accurate records

2. What software programs and programming languages are you proficient in?

CNC Programming

- Mastercam

- SolidWorks

- NX CAM

CAD/CAM Software

- AutoCAD

- Solid Edge

- Creo

3. How do you handle complex or non-standard milling jobs?

When faced with complex or non-standard milling jobs, I employ the following strategies:

- Consult with engineers and designers to understand the intricacies of the project

- Utilize advanced CAM software to create toolpaths and optimize cutting parameters

- Conduct trial runs to refine the machining process and ensure accuracy

- Monitor the milling process closely and make adjustments as needed

4. What quality control measures do you implement to ensure the precision and accuracy of milled products?

To ensure the precision and accuracy of milled products, I implement the following quality control measures:

- Inspecting raw materials and cutting tools before use

- Calibrating CNC machines regularly

- Utilizing measuring instruments such as calipers, micrometers, and CMMs

- Conducting first article inspections and in-process inspections

- Maintaining detailed records of all quality control checks

5. How do you stay up-to-date with the latest advancements in milling technology?

To remain current with the latest advancements in milling technology, I engage in the following activities:

- Attending industry conferences and workshops

- Reading technical journals and publications

- Participating in online forums and discussion groups

- Collaborating with colleagues and experts in the field

6. Can you describe the process of setting up and operating a CNC milling machine?

Setting up and operating a CNC milling machine typically involves the following steps:

- Mounting the workpiece and securing it in place

- Selecting and installing the appropriate cutting tool

- Inputting the CNC program into the machine controller

- Setting up the machine parameters such as spindle speed, feed rate, and depth of cut

- Initiating the milling process and monitoring its progress

7. What types of cutting tools are commonly used in milling operations?

Commonly used cutting tools in milling operations include:

- End mills: For creating slots, pockets, and contours

- Face mills: For surfacing and finishing flat surfaces

- Ball mills: For creating complex shapes and curves

- Form tools: For producing specific profiles

- Drills: For creating holes

8. How do you determine the appropriate cutting parameters for different milling operations?

To determine the appropriate cutting parameters for different milling operations, I consider the following factors:

- Type of material being milled

- Diameter and type of cutting tool

- Desired surface finish

- Spindle speed and torque capabilities of the CNC machine

- Depth of cut and feed rate

9. What are some common troubleshooting techniques for CNC milling machines?

- Inspecting the CNC program for errors

- Checking the cutting tool for wear or damage

- Adjusting the machine parameters

- Verifying the workpiece setup

- Lubricating the machine components

10. How do you ensure the safety of yourself and others while operating a CNC milling machine?

To ensure the safety of myself and others while operating a CNC milling machine, I adhere to the following practices:

- Wearing appropriate safety gear such as gloves, safety glasses, and earplugs

- Keeping the work area clean and organized

- Following established safety protocols and procedures

- Being aware of the machine’s movements and potential hazards

- Never operating the machine while under the influence of drugs or alcohol

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Computerized Mill Recorder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Computerized Mill Recorder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities for Computerized Mill Recorder

A Computerized Mill Recorder is a skilled individual responsible for operating and maintaining computerized mill equipment to produce lumber. Their primary duties encompass:

1. Mill Operation

Operate computerized sawmills and other related equipment to cut logs into various lumber products.

- Monitor and adjust equipment settings to ensure optimal production and quality.

- Troubleshoot and resolve operational issues to maintain smooth mill operations.

2. Quality Control

Inspect lumber products to ensure they meet specified quality standards.

- Identify and sort out defective or non-conforming lumber.

- Collaborate with quality control personnel to identify and implement improvements.

3. Production Management

Plan and schedule production runs to optimize efficiency and meet customer orders.

- Track production volumes and identify areas for improvement.

- Coordinate with other departments to ensure timely product delivery.

4. Safety and Maintenance

Follow all established safety procedures and maintain a clean and organized work environment.

- Perform regular maintenance and inspections on equipment to prevent breakdowns.

- Report any safety hazards or concerns to supervisors.

Interview Preparation Tips for Computerized Mill Recorder

Preparing thoroughly for an interview as a Computerized Mill Recorder can enhance your chances of success. Here are some valuable tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and operations. Understand the specific responsibilities of the Computerized Mill Recorder role and how it aligns with your skills and experience.

- Visit the company website and review any available materials.

- Reach out to current or former employees for insights into the company culture.

2. Practice Your Responses

Prepare for common interview questions by anticipating the areas the interviewer may focus on. Practice your answers to highlight your relevant skills, experience, and qualifications.

- Emphasize your technical proficiency in operating computerized mill equipment.

- Share examples of your problem-solving abilities and commitment to quality.

3. Showcase Your Safety Awareness

Safety is paramount in this industry. Demonstrate your awareness of industry regulations and safety protocols. Highlight your commitment to maintaining a safe work environment.

- Discuss your experience in following established safety procedures.

- Explain your understanding of the importance of regular equipment inspections.

4. Highlight Your Teamwork and Communication Skills

Computerized Mill Recorders often work as part of a team. During the interview, emphasize your ability to work effectively with others, communicate clearly, and collaborate to achieve shared goals.

- Share examples of successful teamwork experiences in previous roles.

- Explain how you approach resolving conflicts and building consensus.

5. Be Enthusiastic and Confident

Throughout the interview, maintain a positive and enthusiastic demeanor. Show your genuine interest in the position and the company. Be confident in your abilities but also open to learning and growing.

- Convey your passion for the industry and your desire to contribute to the team.

- Express your willingness to take on new challenges and responsibilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Computerized Mill Recorder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!