Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Computerized Photofinishing Equipment Service Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Computerized Photofinishing Equipment Service Technician so you can tailor your answers to impress potential employers.

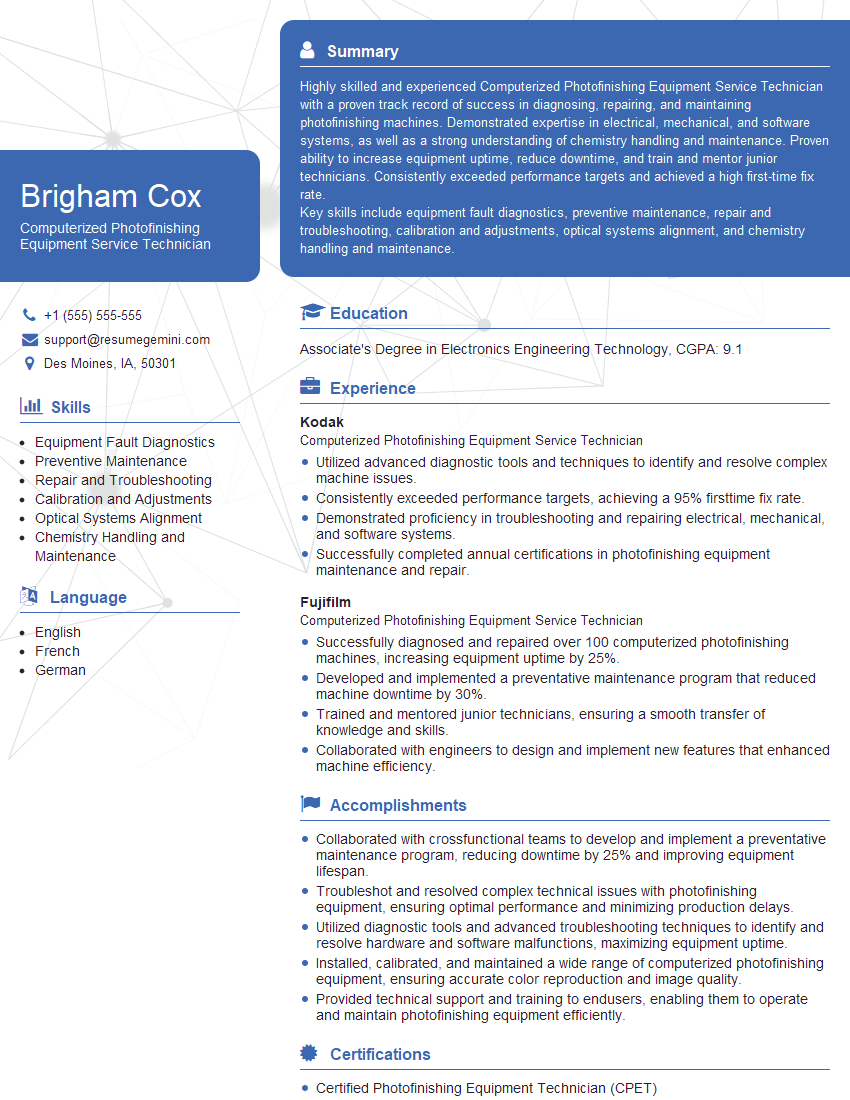

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Computerized Photofinishing Equipment Service Technician

1. Describe the process you would follow to troubleshoot a computerized photofinishing equipment malfunction?

Example Answer

- Identify the symptoms of the malfunction and gather information about the equipment’s recent operation.

- Check the equipment’s power supply, cables, and connections to ensure they are secure and functioning properly.

- Review the equipment’s error logs and diagnostic tools to identify potential error codes.

- Perform hardware diagnostics to test the functionality of the equipment’s components.

- Inspect the equipment for any physical damage or signs of wear and tear.

- Consult the equipment’s technical documentation or seek assistance from the manufacturer for further guidance.

2. How do you stay up-to-date with the latest advancements in computerized photofinishing equipment technology?

Example Answer

- Attend industry conferences and workshops to learn about new technologies and best practices.

- Subscribe to trade publications and technical journals to stay informed about the latest advancements.

- Participate in online forums and discussion groups to connect with other professionals and exchange ideas.

- Obtain certifications from equipment manufacturers to demonstrate proficiency in servicing their products.

- Enroll in continuing education courses or manufacturer training programs to enhance skills and knowledge.

3. Explain the importance of preventative maintenance for computerized photofinishing equipment.

Example Answer

- Prevents unexpected breakdowns and costly repairs by identifying potential issues early on.

- Extends the equipment’s lifespan and ensures optimal performance.

- Reduces downtime and minimizes disruptions to the photofinishing process.

- Improves the equipment’s accuracy and consistency, leading to higher quality finished products.

- Helps identify areas for optimization and efficiency improvements.

4. Describe the safety precautions you take when working with computerized photofinishing equipment.

Example Answer

- Wear appropriate personal protective equipment (PPE), such as safety glasses and gloves.

- Follow lockout/tagout procedures to prevent accidental equipment activation.

- Ensure proper ventilation to avoid exposure to harmful fumes or chemicals.

- Handle equipment with care and avoid touching sensitive components.

- Be aware of electrical hazards and take precautions to prevent shocks or fires.

5. What is your experience with using diagnostic software to troubleshoot computerized photofinishing equipment?

Example Answer

- Proficient in using manufacturer-specific diagnostic software for various photofinishing equipment models.

- Can interpret diagnostic results and identify potential hardware or software issues.

- Use software to perform remote diagnostics and troubleshoot problems without physically being present.

- Stay up-to-date with software updates and enhancements to ensure effective troubleshooting.

6. How do you handle situations where the malfunctioning equipment is no longer under warranty?

Example Answer

- Contact the equipment manufacturer for guidance and technical support.

- Research alternative repair options, such as third-party service providers or independent technicians.

- Assess the cost of repairs and the availability of replacement parts.

- Communicate with the client to provide updates and discuss repair options and costs.

- Document all repairs and maintenance performed on out-of-warranty equipment.

7. Describe a complex repair or troubleshooting scenario you have encountered in your previous role.

Example Answer

- Describe the equipment malfunction and the symptoms it exhibited.

- Explain the troubleshooting process, including tests performed and diagnostic tools used.

- Discuss the root cause of the problem and the steps taken to repair the equipment.

- Highlight the challenges faced and how they were overcome.

- Emphasize the successful resolution of the issue and the impact on the photofinishing process.

8. How do you prioritize repairs and allocate your time when handling multiple service requests?

Example Answer

- Assess the urgency of each request based on the severity of the malfunction and its impact on the business.

- Use a scheduling system or work order management software to track requests and allocate resources.

- Communicate with clients to provide estimated repair times and keep them informed of progress.

- Prioritize repairs that affect critical production processes or revenue-generating equipment.

- Delegate tasks to other technicians or team members when necessary to ensure timely resolution of service requests.

9. How do you ensure customer satisfaction and build strong relationships with clients?

Example Answer

- Provide prompt and courteous service, addressing client concerns efficiently.

- Communicate clearly and keep clients informed of repair progress and timelines.

- Go the extra mile to resolve issues and exceed expectations.

- Maintain a professional and positive attitude, even in challenging situations.

- Seek feedback from clients to identify areas for improvement and enhance customer experience.

10. How do you stay informed about the latest trends and advancements in the photofinishing industry?

Example Answer

- Attend industry events and conferences to network with peers and learn about new technologies.

- Read trade publications and online forums to stay up-to-date on market trends.

- Follow industry leaders and experts on social media for insights and updates.

- Participate in online discussions and webinars to broaden knowledge and share experiences.

- Explore emerging technologies and their potential impact on the photofinishing industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Computerized Photofinishing Equipment Service Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Computerized Photofinishing Equipment Service Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Computerized Photofinishing Equipment Service Technicians are responsible for the installation, maintenance, and repair of computerized photofinishing equipment used in retail stores, photo labs, and other commercial settings. Technicians are also responsible for troubleshooting and resolving issues with equipment components, including software, hardware, and peripherals. The troubleshooting process involves identifying faulty components by using diagnostic tools and knowledge of the equipment and making the necessary repairs or replacements.

1. Installing and Configuring Equipment

Technicians are responsible for installing and configuring photofinishing equipment according to manufacturer’s specifications. This includes unpacking and assembling equipment, connecting cables and peripherals, and installing software and drivers. They must also verify that the equipment is functioning properly before turning it over to the customer.

2. Troubleshooting and Repairing Equipment

Technicians must be able to troubleshoot and repair a variety of equipment problems, including software and hardware issues. Troubleshooting involves identifying faulty components and repairing or replacing them.

3. Preventive Maintenance

Technicians must also perform preventive maintenance on equipment to ensure that it is operating at optimal performance. This includes cleaning, lubricating, and adjusting equipment, and replacing worn or damaged parts.

4. Customer Support

Technicians must be able to provide excellent customer support to customers who are experiencing problems with their equipment. This includes providing technical assistance over the phone or internet, and responding to customer inquiries in a timely and professional manner.

Interview Tips

Preparing for an interview for a Computerized Photofinishing Equipment Service Technician position can be daunting, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and the Position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, goals, and values, and will also give you a better understanding of the specific requirements of the position.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be Prepared to Discuss Your Experience and Skills

The interviewer will want to know about your experience and skills as they relate to the position. Be prepared to discuss your past experience working with photofinishing equipment, as well as your skills in troubleshooting and repair. You should also be able to demonstrate your knowledge of the latest photofinishing technologies.

4. Be Enthusiastic and Professional

Make sure to be enthusiastic and professional during the interview. Dress appropriately, arrive on time, and be respectful of the interviewer’s time. Your enthusiasm for the position and your professionalism will reflect positively on you.

5. Ask Questions

At the end of the interview, be sure to ask the interviewer any questions that you have. This shows that you are interested in the position and that you are engaged in the conversation. It is also an opportunity to learn more about the company and the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Computerized Photofinishing Equipment Service Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.