Are you gearing up for a career in Concaving Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Concaving Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

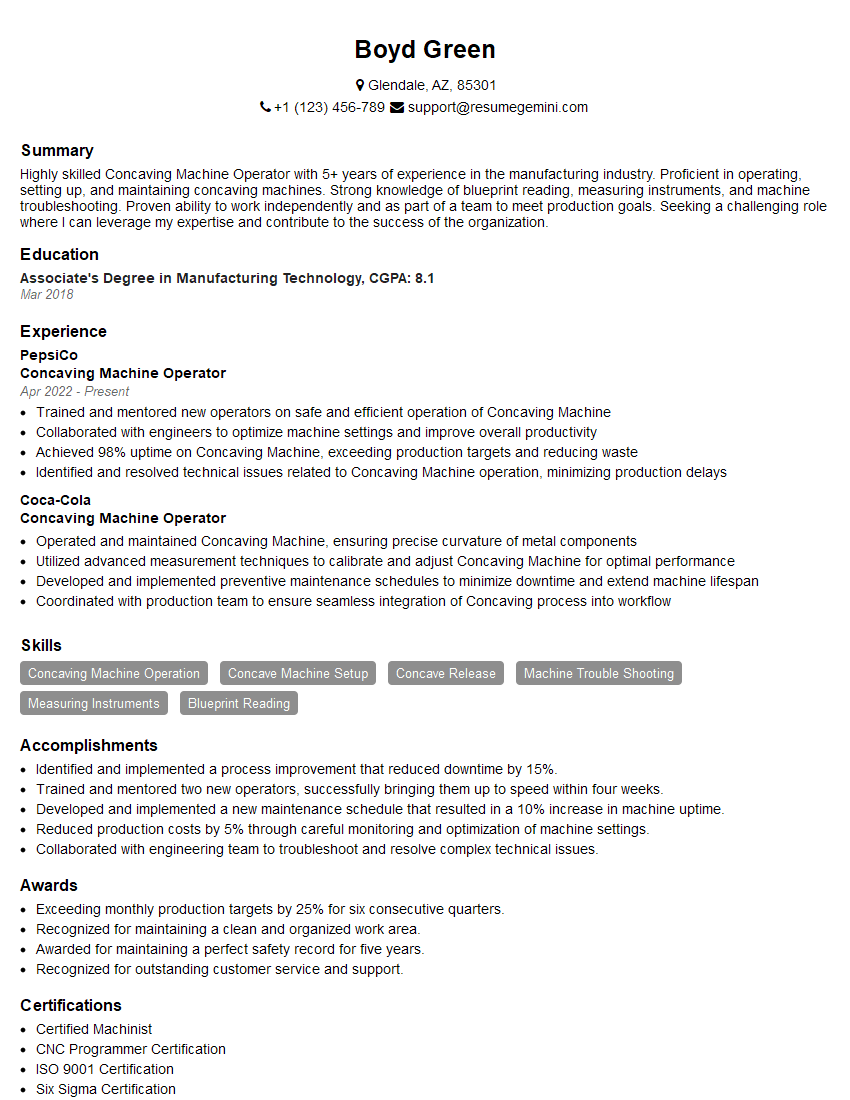

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concaving Machine Operator

1. What is the purpose of a concaving machine?

The primary purpose of a concaving machine is to reduce the size and shape of materials such as rocks, minerals, or ores by crushing and grinding them into smaller pieces. It is commonly used in industries like mining, construction, and recycling to process raw materials for various applications.

2. Describe the different types of concaving machines.

- Jaw crushers: Feature two opposing jaws that move towards and away from each other, crushing materials between them.

- Cone crushers: Utilize a rotating cone that crushes materials against a stationary cone-shaped surface.

- Gyratory crushers: Similar to cone crushers, but with a rotating eccentric cone that provides a more efficient crushing action.

- Impact crushers: Use high-speed rotating hammers or impellers to break materials into smaller pieces.

3. What are the key factors to consider when selecting a concaving machine?

- Material type and size

- Required production capacity

- Desired product size and shape

- Power requirements and energy efficiency

- Maintenance and operating costs

- Space availability

4. Explain the process of setting up and calibrating a concaving machine.

- Install the machine on a stable surface.

- Adjust the concaving plates to the desired product size.

- Calibrate the machine using a standardized material.

- Monitor the machine’s performance and make necessary adjustments.

5. How do you ensure the safety of operators when working with a concaving machine?

- Follow manufacturer’s safety guidelines.

- Wear appropriate personal protective equipment (PPE).

- Keep the work area clean and well-maintained.

- Inspect the machine regularly for any damage or wear.

- Never operate the machine without proper training.

6. What are the common maintenance tasks required for a concaving machine?

- Lubricating moving parts.

- Replacing worn concaving plates.

- Inspecting and adjusting belts or chains.

- Cleaning and removing debris from the machine.

- Conducting regular maintenance checks according to the manufacturer’s recommendations.

7. How do you troubleshoot common problems with a concaving machine?

- Reduced production capacity: Check for worn plates, clogged material, or power issues.

- Uneven product size: Adjust concaving plates, inspect for wear or damage.

- Excessive noise or vibration: Check for loose parts, unbalanced components, or misalignment.

- Overheating: Check lubrication, cooling system, or excessive load.

- Electrical problems: Inspect wiring, fuses, or switches.

8. What are the performance metrics used to evaluate the efficiency of a concaving machine?

- Production rate: Amount of material processed per unit time.

- Product quality: Size, shape, and consistency of the crushed material.

- Energy consumption: Power required to operate the machine.

- Maintenance costs: Labor, parts, and materials required for upkeep.

- Overall equipment effectiveness (OEE): Measure of machine availability, performance, and quality.

9. Describe the role of automation in the operation of concaving machines.

- Automatic feed control: Regulates the material flow into the machine.

- Particle size monitoring: Sensors monitor product size and adjust machine settings accordingly.

- Remote monitoring and control: Allows operators to monitor and control the machine from a central location.

- Predictive maintenance: Alerts operators to potential maintenance issues before they occur.

10. What are the latest advancements in concaving machine technology?

- High-pressure grinding rolls (HPGR): Provide high-efficiency grinding and produce fine-grained materials.

- Autogenous grinding mills: Utilize the material itself as grinding media, reducing energy consumption.

- Sensors and data analytics: Improve process control, optimization, and predictive maintenance.

- Artificial intelligence (AI): Optimizes machine settings and predicts maintenance needs based on real-time data.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concaving Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concaving Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concaving Machine Operators are responsible for operating and maintaining concaving machines, which are used to shape and form metal sheets. They work in a variety of industries, including automotive, aerospace, and electronics.

1. Machine Operation

Concaving Machine Operators must be able to safely and efficiently operate concaving machines. This includes setting up the machine, loading and unloading the metal sheets, and adjusting the machine’s settings to produce the desired results.

- Set up and operate concaving machines to shape and form metal sheets

- Inspect metal sheets for flaws or defects

- Adjust machine settings to produce the desired results

2. Machine Maintenance

Concaving Machine Operators must also be able to perform basic maintenance on the machines they operate. This includes cleaning, lubrication, and minor repairs.

- Perform basic maintenance on concaving machines, including cleaning, lubrication, and minor repairs

- Troubleshoot and resolve common machine problems

- Report any major problems to their supervisor

3. Quality Control

Concaving Machine Operators are responsible for ensuring that the metal sheets they produce meet the required quality standards. This includes inspecting the sheets for flaws or defects, and making adjustments to the machine settings as needed.

- Inspect metal sheets for flaws or defects

- Make adjustments to the machine settings to produce the desired results

- Ensure that the metal sheets meet the required quality standards

4. Safety

Concaving Machine Operators must follow all safety procedures and regulations. This includes wearing appropriate safety gear, and being aware of the potential hazards associated with operating concaving machines.

- Follow all safety procedures and regulations

- Wear appropriate safety gear

- Be aware of the potential hazards associated with operating concaving machines

Interview Tips

Preparing for an interview can be stressful. However, by following a few simple tips, you can increase your chances of success. Here are some tips to help you ace your interview for a Concaving Machine Operator position.

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and what they are looking for in a candidate.

- Visit the company’s website

- Read recent news articles about the company

- Look up the company on social media

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions

- Be prepared to talk about your skills and experience

- Be prepared to talk about why you are interested in the position

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, conservative clothing that is appropriate for an office environment.

- Wear a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Wear comfortable shoes

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. This shows the interviewer that you are respectful of their time.

- Give yourself plenty of time to get to the interview

- Factor in traffic and parking

- If you are running late, call the interviewer to let them know

5. Be positive and enthusiastic

Interviewers are looking for candidates who are positive and enthusiastic about the position. Let your personality shine through and show the interviewer why you are excited about the opportunity.

- Smile and make eye contact with the interviewer

- Be friendly and approachable

- Show your enthusiasm for the position

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Concaving Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Concaving Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.