Are you gearing up for an interview for a Concrete and Asphalt Equipment Crew Member position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Concrete and Asphalt Equipment Crew Member and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

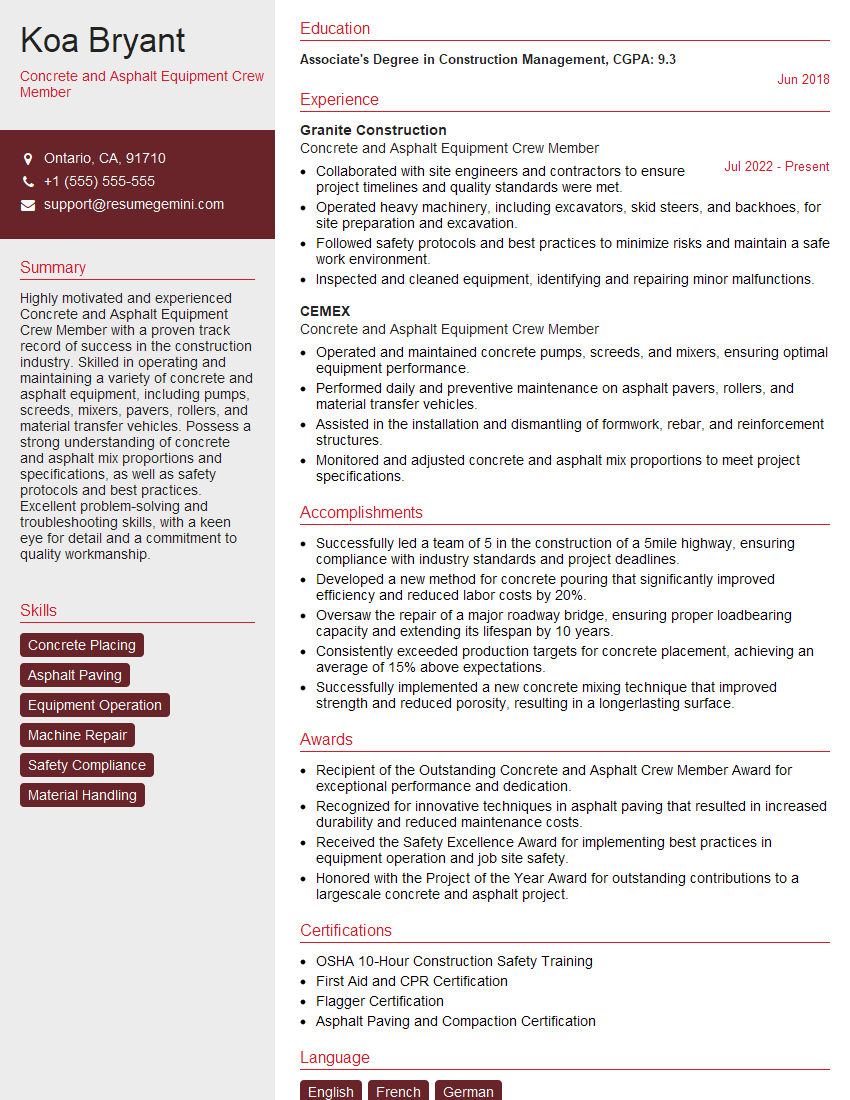

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete and Asphalt Equipment Crew Member

1. What are the key responsibilities of a Concrete and Asphalt Equipment Crew Member?

As a Concrete and Asphalt Equipment Crew Member, my primary responsibilities include:

- Operate and maintain concrete and asphalt equipment, such as mixers, pavers, and rollers.

- Prepare and pour concrete and asphalt surfaces.

- Smooth and compact concrete and asphalt surfaces.

- Inspect and repair concrete and asphalt surfaces.

- Clean and maintain equipment.

- Adhere to safety regulations and guidelines.

2. Can you describe the different types of concrete and asphalt equipment you have operated?

In my previous roles, I have operated a wide range of concrete and asphalt equipment, including:

Concrete Equipment:

- Concrete mixers

- Concrete pavers

- Concrete vibrators

- Concrete finishing machines

Asphalt Equipment:

- Asphalt pavers

- Asphalt rollers

- Asphalt tampers

3. How do you ensure that concrete and asphalt surfaces are properly prepared and finished?

To ensure proper preparation and finishing of concrete and asphalt surfaces, I follow these steps:

- Inspect the work area to identify any potential hazards or obstacles.

- Prepare the surface by removing any debris, moisture, or other contaminants.

- Apply a bonding agent or primer to improve adhesion.

- Place and spread the concrete or asphalt using appropriate techniques and equipment.

- Smooth and compact the surface using vibrators or rollers to achieve the desired density and finish.

- Check the surface for any defects or imperfections and make necessary repairs.

- Allow the surface to cure properly according to manufacturer’s specifications.

4. What safety measures do you take when working with concrete and asphalt equipment?

Safety is paramount when working with concrete and asphalt equipment. I strictly adhere to these safety measures:

- Wear appropriate personal protective equipment (PPE) such as gloves, hard hat, safety glasses, and earplugs.

- Inspect equipment before each use, ensuring it is in good working condition.

- Follow proper operating procedures and never attempt tasks beyond my skill level.

- Maintain a clean and organized work area to minimize hazards.

- Be aware of surroundings and potential hazards, such as falling objects, moving vehicles, or uneven surfaces.

- Report any accidents, injuries, or near misses immediately.

5. How do you troubleshoot common problems that may arise while operating concrete and asphalt equipment?

When troubleshooting common problems with concrete and asphalt equipment, I take the following steps:

- Identify the problem and gather information about the symptoms and operating conditions.

- Refer to equipment manuals or consult with experienced colleagues to diagnose the issue.

- Perform visual inspections, check fluid levels, and test components to pinpoint the root cause.

- Repair or replace faulty components, ensuring they meet specifications.

- Test the equipment to verify that the problem is resolved.

6. What is your experience with concrete and asphalt testing procedures?

In my previous roles, I have performed various concrete and asphalt testing procedures, including:

- Slump test to determine the consistency of concrete.

- Air content test to measure the amount of air bubbles in concrete.

- Compressive strength test to determine the strength of concrete.

- Marshall stability test to evaluate the strength and stability of asphalt.

- Density test to measure the density of asphalt.

7. How do you maintain and calibrate concrete and asphalt equipment?

To ensure optimal performance and accuracy, I follow a regular maintenance and calibration schedule for concrete and asphalt equipment:

- Clean equipment after each use to remove debris and buildup.

- Inspect components for wear and tear, and replace or repair as needed.

- Lubricate moving parts to minimize friction and extend equipment life.

- Calibrate equipment according to manufacturer’s specifications using certified tools and instruments.

- Document maintenance and calibration records for future reference and quality control.

8. What is your experience with working in a team environment on concrete and asphalt projects?

Throughout my career, I have consistently worked effectively in team environments on concrete and asphalt projects. My contributions have included:

- Coordinating with other crew members to ensure smooth workflow and efficient task completion.

- Communicating with project managers and supervisors to provide updates and address any concerns.

- Supporting and assisting other team members as needed.

- Maintaining a positive and collaborative work atmosphere.

9. How do you stay up-to-date with the latest developments and best practices in the concrete and asphalt industry?

To stay current with the latest advancements and best practices in the industry, I actively engage in the following activities:

- Attend industry conferences and workshops.

- Read trade publications and industry-related articles.

- Participate in online forums and discussions.

- Network with professionals in the field.

10. What are your career goals and how do you see this role contributing to your professional development?

My career goals align with my passion for the construction industry and my desire to make a meaningful contribution to infrastructure projects. I am particularly interested in:

- Expanding my knowledge and skills in concrete and asphalt technology.

- Assuming leadership roles and mentoring junior crew members.

- Contributing to the development and implementation of innovative construction practices.

- This role provides an ideal platform for me to achieve these goals by offering opportunities for hands-on experience, collaboration with experienced professionals, and exposure to cutting-edge technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete and Asphalt Equipment Crew Member.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete and Asphalt Equipment Crew Member‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete and Asphalt Equipment Crew Members are responsible for the operation of heavy equipment used in the construction and maintenance of concrete and asphalt surfaces. Their duties may include:

1. Equipment Operation

Operating heavy equipment such as concrete mixers, asphalt pavers, and rollers to construct and repair roads, bridges, and other structures.

2. Equipment Maintenance

Performing routine maintenance and repairs on equipment to ensure it is in good working order.

3. Material Handling

Loading, unloading, and transporting materials to and from the job site.

4. Site Preparation

Preparing the job site for construction, including clearing land, excavating, and grading.

Interview Tips

To ace the interview for a Concrete and Asphalt Equipment Crew Member, it is important to prepare thoroughly. Here are some tips to help you succeed:

1. Research the Company and Position

Learn about the company’s history, values, and products/services. Research the specific position you are applying for, including its responsibilities and qualifications.

- Visit the company’s website and social media pages.

- Read industry news and articles.

- Talk to people who work in the industry.

2. Practice Your Answers to Common Interview Questions

Prepare for common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers in front of a mirror or with a friend or family member.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Highlight your skills and experience that are relevant to the position.

- Be confident and enthusiastic in your responses.

3. Dress Professionally

First impressions matter, so dress appropriately for the interview. This means wearing clean, pressed clothes that are appropriate for the job setting.

- Avoid wearing jeans, T-shirts, or sneakers.

- Opt for khakis, dress pants, or a skirt and blouse.

- Make sure your clothes are clean and wrinkle-free.

4. Be Punctual

Punctuality shows respect for the interviewer’s time. Plan your route to the interview location in advance, and allow yourself plenty of time to get there.

- Leave early to avoid traffic or other delays.

- If you are running late, call the interviewer to let them know.

5. Be Enthusiastic and Positive

Employers are looking for candidates who are passionate about their work. Show your enthusiasm for the position and the company by being positive and engaged during the interview.

- Smile and make eye contact with the interviewer.

- Be confident in your abilities.

- Ask questions about the position and the company.

6. Follow Up

After the interview, send a thank-you note to the interviewer. This is a great way to reiterate your interest in the position and to thank the interviewer for their time.

- Send your thank-you note within 24 hours of the interview.

- Personalize your note and mention something specific that was discussed in the interview.

- Reiterate your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Concrete and Asphalt Equipment Crew Member interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!