Are you gearing up for an interview for a Concrete Block Plant Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Concrete Block Plant Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

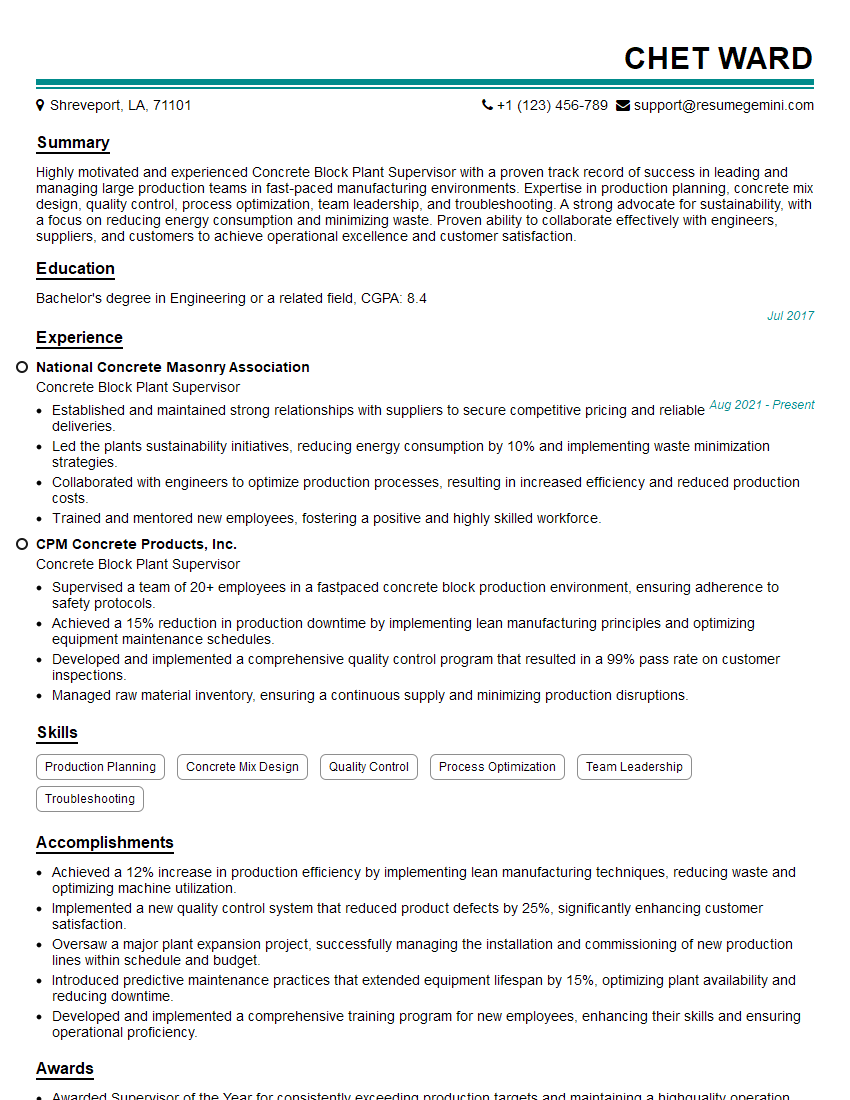

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Block Plant Supervisor

1. What are the key performance indicators (KPIs) you would track to measure the success of a concrete block plant?

- Production volume and efficiency

- Product quality and consistency

- Cost of production

- Customer satisfaction

- Safety and environmental compliance

2. Describe the steps involved in the production of concrete blocks, from raw materials to finished product.

Mixing

- Weighing and blending raw materials (cement, aggregates, water, admixtures)

- Mixing in a concrete mixer to achieve desired consistency

Molding

- Pouring mixed concrete into block molds

- Compacting the concrete using vibration or pressure

Curing

- Storing molded blocks in a controlled environment (temperature, humidity)

- Providing moisture to prevent cracking

Finishing

- Removing finished blocks from molds

- Stacking and packaging for storage or shipment

3. What are common problems encountered in concrete block production and how would you address them?

- Cracking: Caused by rapid drying or shrinkage; can be addressed by proper curing and admixtures

- Efflorescence: Formation of white deposits on the block surface; can be prevented by using non-reactive aggregates

- Strength issues: Affected by mix design, compaction, and curing; can be rectified by adjusting mix proportions or improving compaction techniques

- Dimensional variations: Resulting from mold inaccuracies or mix consistency; can be minimized by calibrating molds and optimizing mixing

- Equipment malfunctions: Require prompt diagnosis and repair to avoid production delays

4. What are the safety hazards associated with concrete block production and how do you mitigate them?

- Falling objects: Ensure proper storage and handling of materials

- Dust inhalation: Provide adequate ventilation and dust masks

- Heavy equipment operation: Train operators and implement safety protocols

- Exposure to chemicals: Use appropriate protective gear and ventilation

- Electrical hazards: Ensure proper grounding and maintenance of equipment

5. How do you manage production schedules and ensure timely delivery to customers?

- Establish a production plan based on customer orders and plant capacity

- Monitor production progress and identify potential bottlenecks

- Coordinate with transportation team to schedule deliveries efficiently

- Communicate any delays or issues to customers promptly

- Implement a quality control system to ensure product specifications are met

6. What maintenance procedures are essential for concrete block plant equipment?

- Regular inspections: Check equipment for wear, damage, or leaks

- Lubrication: Grease and oil moving parts to reduce friction

- Calibration: Verify accuracy of measuring and control devices

- Repairs: Address equipment malfunctions promptly to prevent further damage

- Preventive maintenance: Schedule regular maintenance tasks to extend equipment life

7. How do you train and develop team members to ensure operational efficiency?

- Proper induction: Provide new hires with comprehensive training on plant operations

- On-the-job training: Assign experienced operators to mentor new team members

- Cross-training: Develop multi-skilled employees to cover multiple roles

- Performance evaluations: Regularly assess team members’ progress and provide feedback

- Continuing education: Offer opportunities for professional development and industry knowledge updates

8. What environmental regulations apply to concrete block production and how do you ensure compliance?

- Air pollution control: Minimize dust emissions through dust collectors and moisture controls

- Water pollution control: Treat wastewater and prevent runoff from entering waterways

- Waste management: Dispose of waste materials (e.g., scrap concrete, packaging) properly

- Noise pollution control: Use noise-reducing equipment and barriers

- Regular monitoring and reporting: Track environmental performance and submit reports as required

9. How do you optimize production costs without compromising quality?

- Raw material sourcing: Negotiate competitive prices and consider alternative materials

- Process optimization: Identify areas for efficiency improvements and reduce waste

- Energy efficiency: Use energy-efficient equipment and implement conservation measures

- Maintenance efficiency: Minimize downtime and reduce maintenance costs through preventive maintenance

- Labor optimization: Analyze staffing levels and implement automation where possible

10. How do you stay updated on industry trends and best practices in concrete block manufacturing?

- Attend industry conferences and workshops

- Subscribe to trade publications and online resources

- Network with peers and experts in the field

- Conduct research and explore new technologies

- Participate in continuing education programs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Block Plant Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Block Plant Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Block Plant Supervisors are responsible for overseeing the production of concrete blocks in a manufacturing facility. They play a crucial role in ensuring that the plant operates efficiently, produces high-quality products, and meets production targets.

1. Production Management

- Plan, schedule, and monitor the production process to maximize efficiency and productivity.

- Oversee the operation and maintenance of production equipment, including mixers, molders, and curing systems.

- Monitor raw material inventory levels and coordinate with suppliers to ensure continuous operation.

2. Quality Control

- Implement and maintain quality control procedures to ensure that concrete blocks meet industry standards and customer specifications.

- Conduct regular inspections of finished products and identify any defects or non-conformances.

- Work with engineers and production staff to improve product quality and reduce waste.

3. Employee Supervision

- Lead, motivate, and develop a team of production employees.

- Provide training on safety procedures, production techniques, and quality standards.

- Evaluate employee performance and provide feedback to improve productivity and job satisfaction.

4. Safety Management

- Implement and enforce safety protocols to ensure a safe and healthy work environment.

- Conduct regular safety inspections and identify potential hazards.

- Train employees on safety procedures and provide personal protective equipment.

Interview Tips

To ace an interview for a Concrete Block Plant Supervisor position, consider the following tips:

1. Research the Company and Position

- Visit the company’s website and social media pages to gather information about their products, services, and culture.

- Review the job description thoroughly to understand the specific responsibilities and qualifications required.

2. Highlight Relevant Experience and Skills

- Emphasize your experience in production management, quality control, and employee supervision.

- Quantify your accomplishments whenever possible, using specific metrics and results.

- Showcase your knowledge of concrete block manufacturing processes, equipment, and industry standards.

3. Demonstrate Leadership and Communication Skills

- Provide examples of how you have successfully led and motivated teams.

- Highlight your ability to communicate effectively with employees, managers, and customers.

- Explain how you foster a positive and collaborative work environment.

4. Be Prepared for Technical Questions

- Review common concrete block manufacturing techniques, such as dry cast, wet cast, and semi-dry cast.

- Be familiar with the properties of concrete, including strength, durability, and moisture resistance.

- Practice troubleshooting common production problems, such as block cracking, efflorescence, and shrinkage.

5. Ask Thoughtful Questions

- Prepare questions that demonstrate your interest in the company, position, and industry.

- Ask about the production capacity, quality control measures, and future growth plans of the facility.

- Inquire about the safety protocols and employee development opportunities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Concrete Block Plant Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.