Are you gearing up for an interview for a Concrete Engineering Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Concrete Engineering Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

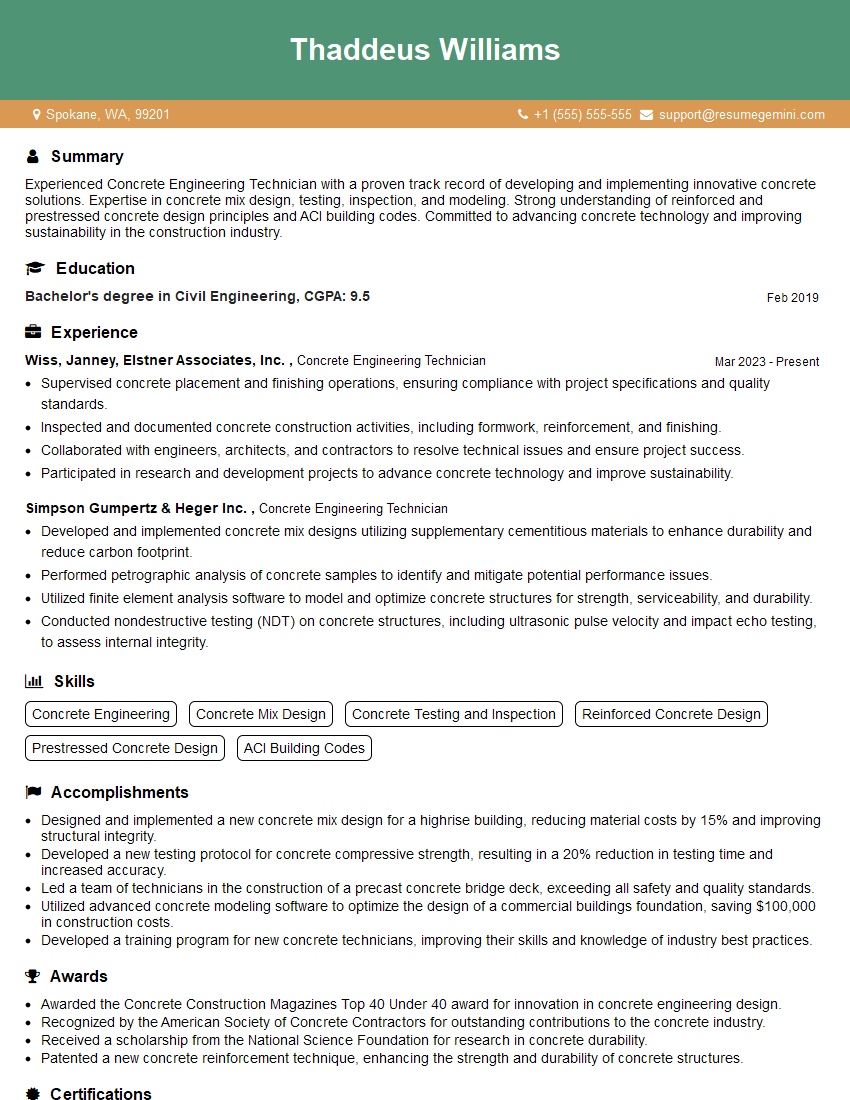

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Engineering Technician

1. What are the primary factors that affect the strength of concrete?

The primary factors that affect the strength of concrete are:

- Water-to-cement ratio: A lower water-to-cement ratio results in a stronger concrete.

- Aggregate type and size: The type and size of aggregate used can affect the strength and durability of concrete.

- Curing conditions: Proper curing conditions, such as adequate moisture and temperature, are essential for concrete to reach its full strength.

- Mix design: The mix design, which includes the proportions of cement, aggregate, water, and any admixtures, significantly impacts the strength of concrete.

2. Explain the role of reinforcing steel in concrete structures.

Strength and Ductility

- Reinforcing steel provides tensile strength to concrete, which is weak in tension.

- It enhances the ductility of concrete structures, allowing them to deform under load without breaking.

Crack Control

- Reinforcing steel helps control cracking in concrete, which can weaken the structure.

- By distributing stresses and preventing uncontrolled cracking, it maintains the integrity and durability of the structure.

3. What are the different types of concrete admixtures, and how do they affect concrete properties?

- Water-reducing admixtures: Reduce the water-to-cement ratio, improving strength and durability.

- Retarding admixtures: Delay the setting time of concrete, allowing for better placement and finishing.

- Accelerating admixtures: Speed up the setting time of concrete, useful in cold weather or for early strength gain.

- Superplasticizers: Greatly increase the workability of concrete without adding water, improving flow and pumpability.

- Air-entraining admixtures: Introduce tiny air bubbles into concrete, enhancing freeze-thaw resistance.

4. Describe the process of concrete quality control, including sampling, testing, and evaluation.

- Sampling: Representative samples are taken from fresh or hardened concrete.

- Testing: Samples undergo tests such as slump test, compressive strength test, and air content test to assess properties.

- Evaluation: Test results are compared to specified standards and project requirements to determine if the concrete meets quality specifications.

5. Explain the importance of mix design in concrete production.

- Optimizes Strength and Durability: Mix design ensures the concrete meets the required strength and durability for the intended application.

- Cost-Effective: It helps minimize the use of expensive materials while maintaining the desired properties.

- Workability and Placeability: Mix design considers factors like workability and placeability to ensure ease of handling and construction.

- Environmental Considerations: It allows for the incorporation of sustainable materials and reduces the environmental impact of concrete production.

6. What are the common causes of concrete cracking, and how can they be prevented?

- Drying Shrinkage: As concrete cures, it loses moisture and shrinks, causing cracks. Prevent by proper curing and using shrinkage-compensating concrete.

- Thermal Expansion and Contraction: Concrete expands and contracts with temperature changes. Prevent by using expansion joints and insulation.

- Overloading: Concrete can crack under excessive loads. Prevent by designing structures to withstand anticipated loads.

- Poor Construction Practices: Improper placement, inadequate reinforcement, or early removal of formwork can lead to cracking. Prevent by following proper construction techniques.

7. Discuss the advantages and disadvantages of using precast concrete elements.

Advantages

- Quality Control: Precasting allows for better quality control in a controlled environment.

- Faster Construction: Precast elements can be installed quickly, reducing construction time.

- Architectural Flexibility: Precast elements offer various shapes and finishes, enhancing design possibilities.

Disadvantages

- Transportation and Handling: Precast elements require careful transportation and handling due to their size and weight.

- Site Limitations: The size and weight of precast elements may pose challenges on sites with limited space or access.

8. Explain the different methods for reinforcing concrete structures, and discuss their respective strengths and weaknesses.

- Reinforcing Bars: Steel bars embedded in concrete provide tensile strength. Advantages: High strength, widely available. Disadvantages: Labor-intensive to install.

- Welded Wire Fabric: A grid of welded steel wires placed in concrete. Advantages: Easy to install, economical. Disadvantages: Lower strength than reinforcing bars.

- Fiber Reinforcement: Small fibers added to concrete enhance its toughness and crack resistance. Advantages: Uniform distribution, improves durability. Disadvantages: Can affect workability.

9. Describe the process of concrete finishing, including methods and techniques used to achieve different surface textures.

- Troweling: Smoothing the concrete surface for a dense, wear-resistant finish.

- Floating: Leveling and compacting the concrete surface to prepare for further finishing.

- Brooming: Creating a textured surface by dragging a broom across the wet concrete.

- Stamping: Impressing patterns or designs onto the concrete surface using special tools.

10. What are the key considerations for concrete repair and rehabilitation?

- Assessment: Thoroughly evaluating the damage to determine the extent of repair required.

- Repair Materials: Selecting appropriate materials that match the existing concrete and meet the performance requirements.

- Application Techniques: Using proper techniques to ensure proper adhesion, durability, and restoration of structural integrity.

- Testing and Monitoring: Conducting tests to verify the effectiveness of the repairs and ongoing monitoring to ensure long-term performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Engineering Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Engineering Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Engineering Technicians play a crucial role in the construction industry by providing technical assistance and ensuring the proper execution of concrete projects.

1. Assist in Concrete Design and Development

Support engineers in developing concrete mix designs, performing laboratory tests, and analyzing data to optimize concrete performance.

2. Conduct Field Testing and Inspections

Conduct field testing on concrete materials, including slump, air content, and strength tests. Inspect concrete placements and monitor curing conditions to ensure compliance with specifications.

3. Manage Concrete Production and Placement

Coordinate with concrete suppliers, contractors, and construction crews to manage concrete production, delivery, and placement. Ensure proper mixing, transportation, and placement techniques are followed.

4. Provide Technical Support and Troubleshooting

Provide technical support to project teams, contractors, and customers. Troubleshoot concrete-related issues, recommend solutions, and monitor performance to ensure project success.

5. Maintain Documentation and Records

Document concrete test results, inspection reports, and other project-related information. Maintain accurate records and prepare technical reports for project files and regulatory compliance.

Interview Tips

Preparing thoroughly for a Concrete Engineering Technician interview is essential to showcase your skills and knowledge.

1. Research the Company and Position

Familiarize yourself with the company’s history, projects, and industry reputation. Review the job description carefully to identify key responsibilities and qualifications.

2. Highlight Your Technical Expertise

Emphasize your understanding of concrete science, testing procedures, and industry standards. Share examples of projects where you successfully applied your technical knowledge to solve problems or improve outcomes.

3. Showcase Your Field Experience

Discuss your experience conducting field tests, inspections, and monitoring concrete placements. Provide specific examples of how your observations and recommendations have contributed to project success.

4. Demonstrate Problem-Solving Abilities

Prepare examples of how you have approached and solved concrete-related challenges in the past. Describe your analytical approach, use of resources, and communication skills in resolving issues.

5. Prepare Questions for the Interviewer

Prepare thoughtful questions to ask the interviewer about the company, the position, and the industry trends. Asking insightful questions demonstrates your interest and engagement.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Concrete Engineering Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.