Are you gearing up for a career in Concrete Finishing Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Concrete Finishing Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

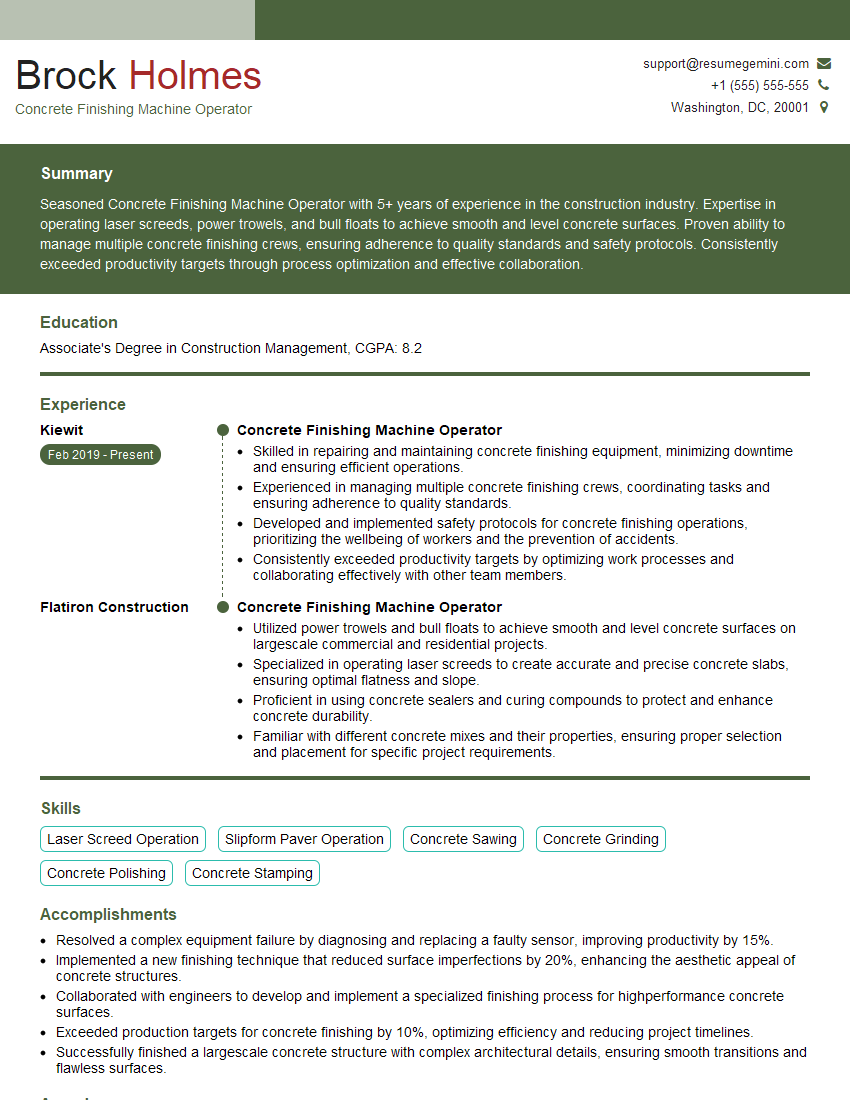

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Finishing Machine Operator

1. What are the different types of concrete finishing machines?

There are various types of concrete finishing machines used for different purposes, including:

- Power trowels: Used for smoothing and leveling concrete surfaces.

- Laser screeds: Employed to level and compact concrete to achieve precise grades and slopes.

- Ride-on trowels: Large machines used for finishing large concrete areas, such as floors and highways.

- Hand trowels: Smaller, handheld tools used for finishing smaller areas or for detail work.

- Edgers: Specialized machines designed to finish the edges of concrete slabs and create decorative borders.

2. What are the key factors to consider when selecting a concrete finishing machine?

Job Requirements:

- Size and shape of the concrete area

- Desired level of finish

- Specific requirements of the project

Machine Features:

- Power and torque capabilities

- Blade or trowel size

- Maneuverability and ease of use

- Reliability and durability

3. How do you ensure the safety of yourself and others when operating concrete finishing machines?

Safety is paramount, and I adhere to the following practices to ensure it:

- Wear proper personal protective equipment (PPE) such as hard hats, safety glasses, and gloves.

- Inspect the machine thoroughly before each use, checking for any damage or loose parts.

- Operate the machine in well-ventilated areas to avoid exposure to harmful fumes.

- Be aware of the surroundings and maintain a safe distance from others.

- Follow all manufacturer’s instructions and safety guidelines.

4. How do you maintain and troubleshoot concrete finishing machines?

Regular maintenance and troubleshooting are crucial for optimal performance:

Maintenance:

- Clean the machine thoroughly after each use to remove concrete residue.

- Lubricate moving parts as per manufacturer’s recommendations.

- Inspect and tighten bolts and connections.

Troubleshooting:

- Identify the problem by observing symptoms and checking the machine’s condition.

- Consult the operator’s manual or troubleshoot guides for possible solutions.

- If unable to resolve the issue, contact the manufacturer or a qualified technician.

5. What is the importance of proper concrete curing?

Proper concrete curing is essential for the following reasons:

- Improves concrete strength and durability by allowing hydration to occur properly.

- Reduces the risk of cracking and shrinking by maintaining moisture levels.

- Enhances the concrete’s resistance to abrasion and wear.

- Promotes a smoother and more uniform surface finish.

6. How do you determine the correct timing and methods for curing concrete?

The timing and methods for curing concrete depend on various factors:

Timing:

- Start curing as soon as the concrete has set.

- Continue curing for a minimum of 7 days, or longer in hot or dry conditions.

Methods:

- Water curing: Spraying or ponding water on the concrete surface.

- Membrane curing: Applying a curing compound that forms a moisture-retaining barrier.

- Plastic sheeting: Covering the concrete with plastic to prevent evaporation.

7. What are the common challenges you have faced as a concrete finishing machine operator?

Some common challenges I have encountered include:

- Working in extreme weather conditions, such as heat, cold, or rain.

- Handling large and heavy equipment safely and efficiently.

- Achieving the desired finish quality within the specified time frame.

- Troubleshooting and repairing equipment malfunctions on the job site.

- Coordinating with other crew members to ensure smooth and timely project completion.

8. How do you stay up-to-date on the latest techniques and equipment in concrete finishing?

To stay current with the industry, I engage in the following practices:

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Network with other concrete professionals.

- Seek training from manufacturers and suppliers on new equipment and techniques.

- Follow industry best practices and guidelines.

9. How do you handle working as part of a team on a concrete construction project?

Teamwork is crucial in concrete construction:

- Effectively communicate and coordinate with team members.

- Share knowledge and expertise to solve problems collectively.

- Contribute to a positive and collaborative work environment.

- Maintain flexibility and adaptability to changing project requirements.

- Support team goals and work towards achieving project success.

10. Why are you interested in working as a concrete finishing machine operator for our company?

I am eager to join your company as a concrete finishing machine operator due to the following reasons:

- Your company’s reputation for quality workmanship and customer satisfaction.

- The opportunity to work on challenging and large-scale projects.

- The company’s commitment to employee training and development.

- The chance to contribute my skills and experience to your team.

- The alignment of your company’s values with my own work ethic.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Finishing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Finishing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Finishing Machine Operators are responsible for ensuring the smooth and level surface of newly poured concrete.

1. Operate Concrete Finishing Machines

Operate a variety of concrete finishing machines including power trowels, laser screeds, and bull floats to smooth and level concrete surfaces.

2. Maintain Equipment

Perform routine maintenance and repairs on equipment to ensure proper operation.

3. Monitor Concrete Quality

Monitor the quality of the concrete finish to ensure it meets specifications.

4. Inspect Completed Work

Inspect completed work for defects and ensure it meets quality standards.

5. Communicate with Crew

Communicate effectively with other crew members to ensure coordination and safety on site.

Interview Tips

To ace the interview for a Concrete Finishing Machine Operator position, it is important to be well-prepared and demonstrate your skills and experience.

1. Research the Company and Position

Gather information about the company, its projects, and the specific position you are applying for.

2. Highlight Relevant Experience

Emphasize your experience operating concrete finishing machines and maintaining equipment.

3. Demonstrate Attention to Detail

Concrete finishing requires precision and attention to detail. Describe instances where you have successfully achieved a smooth and level concrete surface.

4. Showcase Teamwork Skills

Concrete finishing often involves working with a team. Highlight your ability to communicate effectively and collaborate with others.

5. Prepare for Technical Questions

Be prepared to answer questions about different types of concrete finishing machines and techniques.

Example Outline for Interview Questions

Here is an outline you can use to structure your answers to interview questions:

- STAR Method:

- Situation: Describe the situation or challenge you faced.

- Task: Explain the task or problem you were responsible for.

- Action: Describe the specific actions you took to address the situation.

- Result: Quantify and describe the positive outcomes of your actions.

- Behavioral Questions:

- Describe a time when you had to overcome a difficult situation on the job.

- Tell me about a time when you had to work effectively as part of a team.

- Give me an example of how you have demonstrated attention to detail in your work.

By following these tips and preparing thoroughly, you can increase your chances of success in your interview for a Concrete Finishing Machine Operator position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Concrete Finishing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.