Are you gearing up for an interview for a Concrete Form Setter and Finisher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Concrete Form Setter and Finisher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

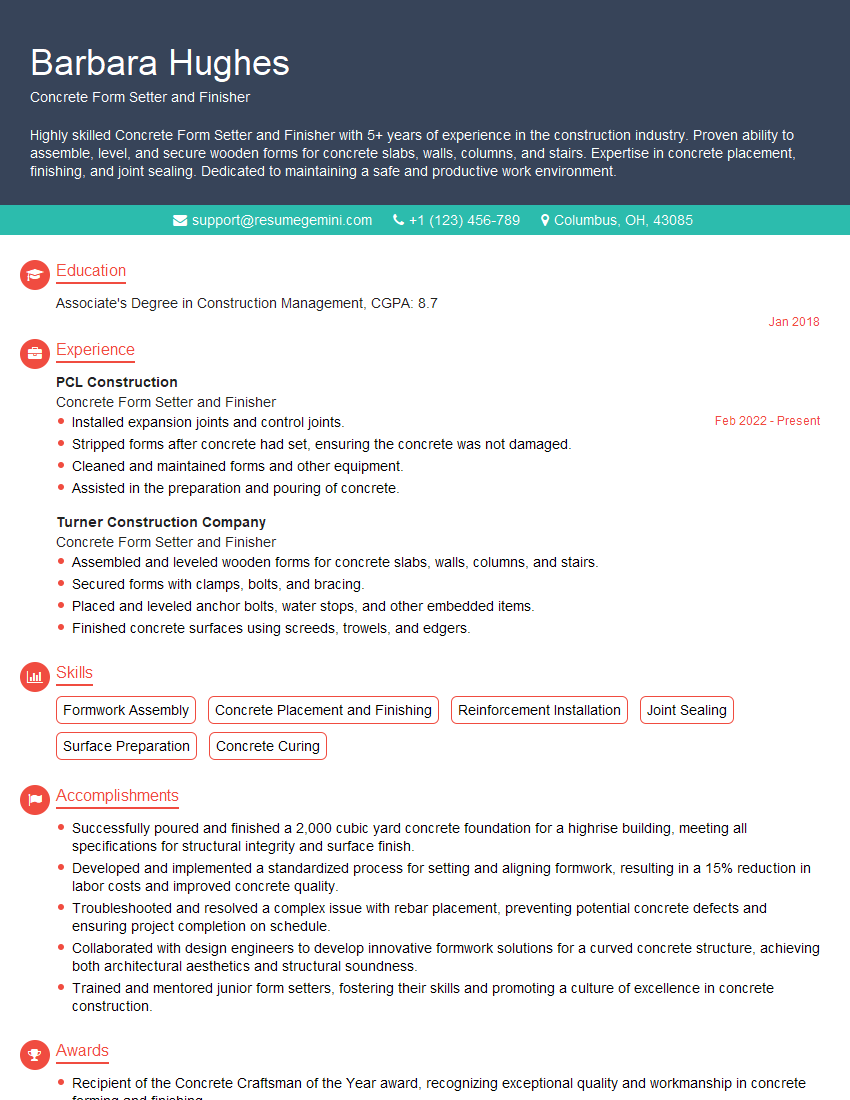

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Form Setter and Finisher

1. What are the different types of concrete forms and their applications?

There are various types of concrete forms, each suitable for specific applications. Some common types include:

- Wood forms: Traditional and versatile, used in both residential and commercial construction.

- Metal forms: Strong and durable, often used for complex shapes and large-scale projects.

- Plastic forms: Lightweight and reusable, ideal for intricate designs and curved surfaces.

- Insulated concrete forms (ICFs): Combine insulation with concrete, providing energy efficiency.

- Tilt-up concrete forms: Large panels cast horizontally and then tilted upright into place.

2. How do you ensure proper alignment and leveling of concrete forms?

Checking Alignment

- Use a transit level or laser level to establish reference points.

- Align forms using string lines or batter boards.

- Check diagonals to ensure squareness of forms.

Leveling Forms

- Use a level or leveling rod to determine the height.

- Adjust formwork using wedges or shims as needed.

- Ensure all forms are at the same level for a uniform concrete surface.

3. How do you prepare and treat form surfaces before concrete placement?

Proper form preparation is crucial to ensure a smooth and durable concrete surface:

- Clean and remove debris, dust, and dirt.

- Apply form release agents to prevent concrete adhesion.

- Oil or wet forms to prevent absorption and ensure a smooth finish.

- Inspect forms for any damage or gaps to prevent concrete leakage.

4. What techniques do you use to consolidate and finish concrete surfaces?

Consolidation

- Use vibrators to remove air pockets and achieve even density.

- Ensure proper consolidation, especially in corners and around reinforcements.

Finishing

- Screed concrete to level and shape the surface.

- Float the surface to remove any imperfections and create a smooth finish.

- Trowel the surface for a dense and durable finish.

5. How do you handle unexpected weather conditions during concrete placement?

Unforeseen weather requires prompt action to protect the concrete:

- In cold weather, protect concrete with insulated blankets or heated enclosures.

- Add accelerators to the mix to speed up curing in cold conditions.

- In hot weather, shade the concrete and use retarders to slow down curing.

- Apply misting systems or cover the surface with wet burlap to prevent rapid drying.

6. What safety measures do you follow when working with concrete forms and finishing equipment?

Safety is paramount in concrete work:

- Wear appropriate PPE, including gloves, safety glasses, and sturdy shoes.

- Inspect equipment regularly and ensure it is in good working order.

- Be aware of potential hazards, such as trip hazards and falling objects.

- Follow manufacturer’s instructions for safe operation of equipment.

7. How do you troubleshoot common problems encountered during concrete formwork?

Troubleshooting is essential to ensure successful concrete placement:

- Identify the problem accurately, such as leaking forms or uneven surfaces.

- Check for any errors in formwork assembly or setup.

- Adjust wedges or shims to correct alignment and leveling issues.

- Use patching materials to repair any leaks or defects.

8. How do you estimate the amount of concrete needed for a given project?

Accurate estimation is crucial for efficient material management:

- Calculate the volume of the concrete structure using measurements and formulas.

- Consider the type of concrete mix and any special requirements.

- Factor in waste and spillage during placement.

- Coordinate with the concrete supplier to ensure timely delivery.

9. What steps do you take to ensure the quality of finished concrete surfaces?

Quality control is essential for durable and aesthetically pleasing concrete:

- Use high-quality materials and follow proper mixing procedures.

- Consolidate concrete effectively to eliminate air pockets and voids.

- Finish the surface properly to achieve the desired texture and smoothness.

- Protect the concrete during curing to prevent cracking or damage.

10. How do you work effectively as part of a construction team?

Teamwork is crucial for successful project execution:

- Communicate clearly with other team members.

- Understand project plans and follow instructions.

- Provide support and assistance to colleagues.

- Maintain a positive and collaborative work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Form Setter and Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Form Setter and Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Form Setters and Finishers play a vital role in shaping concrete structures. Their responsibilities encompass various aspects:

1. Form Preparation

Laying the groundwork for concrete structures

- Assembles, aligns, and secures formwork systems as per blueprints.

- Measures, cuts, and adjusts form materials like plywood and lumber.

2. Reinforcement Installation

Ensuring structural integrity

- Positions and secures steel reinforcement bars (rebar) within the formwork.

- Ensures proper spacing and alignment of rebar.

3. Concrete Placement

Handling the heart of the structure

- Participates in concrete placement and consolidation activities.

- Ensures even distribution and proper filling of concrete into forms.

4. Finishing Touches

Shaping the final form

- Strips forms and finishes concrete surfaces to meet specifications.

- Applies curing compounds or membranes to protect concrete surfaces.

Interview Tips

Preparing for an interview as a Concrete Form Setter and Finisher requires a well-rounded approach. Here are some key tips to help you ace the interview:

1. Research the Company and Job Role

Familiarize yourself with the company’s history, projects, and culture. Additionally, thoroughly review the job description to understand the specific requirements and expectations.

2. Highlight Your Experience and Skills

Emphasize your practical experience in formwork assembly, rebar installation, concrete placement, and finishing techniques. Quantify your accomplishments with specific examples whenever possible.

3. Soft Skills Matter

Beyond technical proficiency, demonstrate strong teamwork, communication, and problem-solving skills. Employers value candidates who can collaborate effectively and adapt to changing site conditions.

4. Prepare for Technical Questions

Expect questions about construction materials, formwork systems, and concrete placement techniques. Be prepared to discuss your understanding of industry standards and safety protocols.

5. Practice Your Answers

Anticipate common interview questions and practice your responses. This will build your confidence and ensure your answers are clear and concise during the actual interview.

6. Ask Informed Questions

At the end of the interview, don’t hesitate to ask thoughtful questions about the company, the project, or your potential role. This shows you’re engaged and interested in the opportunity.

7. Follow Up Professionally

After the interview, send a thank-you note to the interviewer. Reiterate your interest in the position and briefly highlight your qualifications. This serves as a professional reminder of your application.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Concrete Form Setter and Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!