Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Concrete Handler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

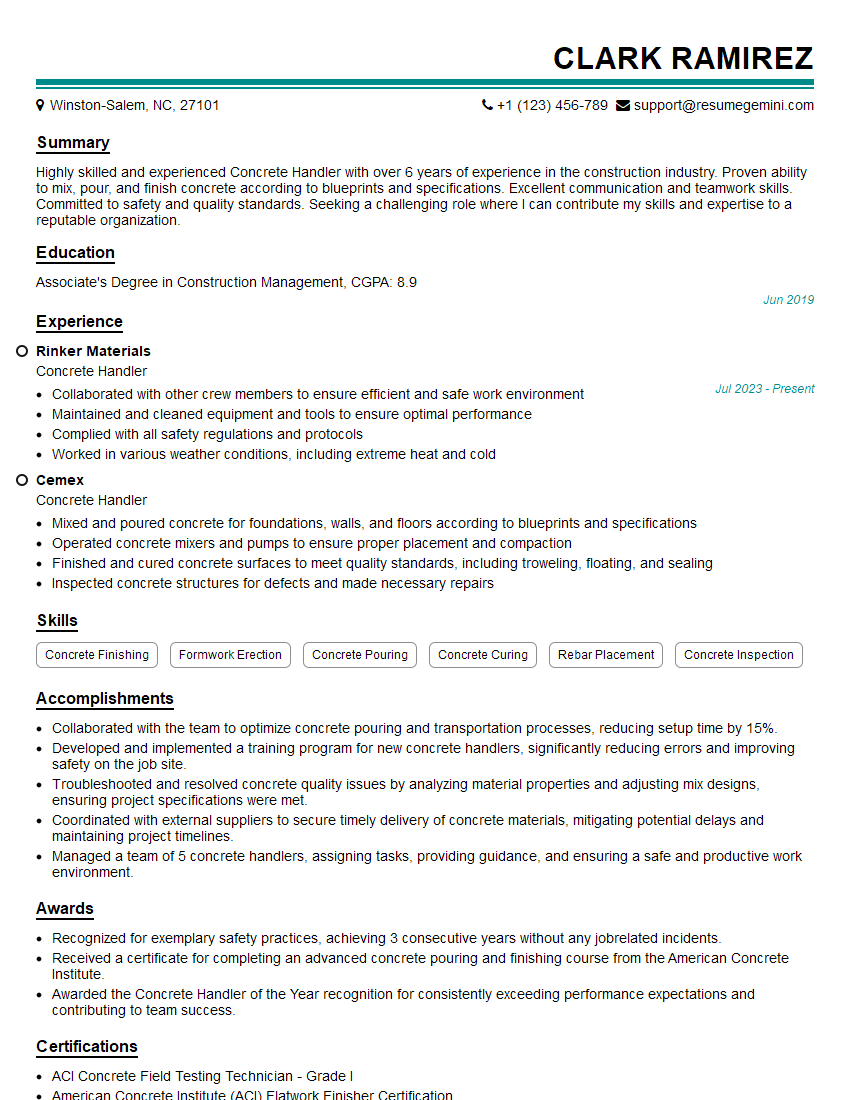

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Handler

1. What are the different types of concrete and their uses?

There are many different types of concrete, each with its own unique properties and applications. Some of the most common types include:

- Normal concrete: This is the most common type of concrete, and it is used for a wide variety of applications, including foundations, walls, and pavements.

- High-strength concrete: This type of concrete has a higher compressive strength than normal concrete, and it is used for applications where strength is critical, such as bridges and high-rise buildings.

- Lightweight concrete: This type of concrete is made with lightweight aggregates, such as pumice or fly ash. It is used for applications where weight is a concern, such as roofing and insulation.

- Self-compacting concrete: This type of concrete flows easily into place, and it does not require vibration. It is used for applications where it is difficult to place concrete, such as narrow forms or congested areas.

2. What are the different methods of placing concrete?

There are several different methods of placing concrete, each with its own advantages and disadvantages. Some of the most common methods include:

Pumping

- Pumping is a fast and efficient way to place concrete. It is used for large pours, such as foundations and slabs.

Chuting

- Chuting is a less expensive way to place concrete than pumping. It is used for smaller pours, such as walls and columns.

Bucketing

- Bucketing is a slow and labor-intensive way to place concrete. It is used for small pours, such as repairs and patches.

3. What are the different methods of finishing concrete?

There are many different methods of finishing concrete, each with its own unique appearance. Some of the most common methods include:

- Troweling: Troweling is a process of smoothing the surface of concrete using a trowel. It can be used to create a variety of different finishes, from a smooth, polished surface to a rough, textured surface.

- Brooming: Brooming is a process of creating a textured surface on concrete using a broom. It is a popular finish for patios and driveways.

- Stamping: Stamping is a process of creating a pattern or design on the surface of concrete using a stamp. It is a popular finish for decorative concrete.

- Exposing aggregate: Exposing aggregate is a process of removing the surface layer of concrete to expose the aggregate. It is a popular finish for driveways and patios.

4. What are the different types of concrete admixtures and their uses?

Concrete admixtures are chemicals that can be added to concrete to improve its properties. Some of the most common types of admixtures include:

- Water reducers: Water reducers reduce the amount of water needed to make concrete workable. They can improve the strength, durability, and appearance of concrete.

- Air-entraining agents: Air-entraining agents introduce small air bubbles into concrete. They improve the durability of concrete by reducing the damage caused by freezing and thawing.

- Accelerators: Accelerators speed up the setting time of concrete. They are used in cold weather or when it is necessary to get concrete into place quickly.

- Retarders: Retarders slow down the setting time of concrete. They are used in hot weather or when it is necessary to delay the setting time of concrete.

5. What are the different types of concrete reinforcement and their uses?

Concrete reinforcement is used to improve the strength and durability of concrete. Some of the most common types of reinforcement include:

- Steel rebar: Steel rebar is the most common type of concrete reinforcement. It is made of steel bars that are placed in the concrete.

- Fiber reinforcement: Fiber reinforcement is made of small fibers that are added to the concrete mix. It improves the strength and toughness of concrete.

- Wire mesh: Wire mesh is made of welded wire that is placed in the concrete.

6. What are the different types of concrete curing methods and their uses?

Concrete curing is the process of keeping concrete moist so that it can gain strength. Some of the most common curing methods include:

- Water curing: Water curing is the most effective way to cure concrete. It involves keeping the concrete surface wet for a period of time.

- Moist curing: Moist curing involves keeping the concrete surface damp using a burlap or plastic sheet.

- Steam curing: Steam curing is a process of curing concrete using steam. It is used to accelerate the curing process.

7. What are the different types of concrete testing methods and their uses?

Concrete testing is used to determine the strength and durability of concrete. Some of the most common testing methods include:

- Compressive strength test: The compressive strength test is used to measure the strength of concrete under compression.

- Tensile strength test: The tensile strength test is used to measure the strength of concrete under tension.

- Flexural strength test: The flexural strength test is used to measure the strength of concrete under bending.

8. What are the different types of concrete defects and their causes?

Concrete defects can occur for a variety of reasons, including poor workmanship, improper materials, and environmental conditions. Some of the most common types of defects include:

- Cracking: Cracking is one of the most common defects in concrete. It can be caused by a variety of factors, including thermal stress, shrinkage, and settlement.

- Spalling: Spalling is the chipping or flaking of the surface of concrete. It can be caused by a variety of factors, including freeze-thaw cycles, corrosion, and impact.

- Honeycombing: Honeycombing is the presence of voids or pockets in concrete. It can be caused by a variety of factors, including improper consolidation, bleeding, and segregation.

9. What are the different types of concrete repair methods and their uses?

Concrete repair methods are used to repair damaged concrete. Some of the most common methods include:

- Patching: Patching is a process of repairing small areas of damaged concrete. It involves removing the damaged concrete and replacing it with new concrete.

- Overlay: An overlay is a layer of new concrete that is placed over damaged concrete. It is used to repair larger areas of damaged concrete.

- Injection: Injection is a process of repairing cracks and voids in concrete by injecting a resin or grout into the cracks.

10. What are the different types of concrete safety hazards and how to prevent them?

Concrete work can be hazardous, and it is important to be aware of the potential hazards and how to prevent them. Some of the most common hazards include:

- Slip and fall hazards: Slip and fall hazards can occur on wet or slippery concrete surfaces. To prevent these hazards, it is important to wear slip-resistant shoes and to keep work areas clean and dry.

- Electrical hazards: Electrical hazards can occur when working with concrete saws, drills, and other power tools. To prevent these hazards, it is important to use properly grounded equipment and to follow all safety guidelines.

- Chemical hazards: Chemical hazards can occur when working with concrete admixtures and other chemicals. To prevent these hazards, it is important to wear proper protective clothing and to follow all safety guidelines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Handler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Handler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Handlers are responsible for the safe and efficient handling of concrete during construction projects. Key responsibilities include:

1. Concrete Mixing and Placement

Loading, mixing, and pouring concrete according to specifications

2. Concrete Finishing

Smoothing, leveling, and finishing concrete surfaces using tools such as trowels and screeds

3. Concrete Forms and Reinforcements

Setting up and removing concrete forms and installing reinforcing materials

4. Equipment Operation

Operating concrete mixers, pumps, and other equipment safely and efficiently

Interview Tips

Preparing thoroughly for an interview can boost your confidence and increase your chances of success. Here are some tips to help you ace your Concrete Handler interview:

1. Research the Company and Position

Learn about the company’s history, mission, and values. Research the specific job requirements and responsibilities to tailor your answers accordingly.

2. Highlight Relevant Skills and Experience

Emphasize your experience in concrete handling, including any specific techniques or equipment you are proficient with. Quantify your accomplishments with data whenever possible.

3. Showcase Safety Awareness

Concrete handling involves potential hazards. Highlight your commitment to safety by describing your experience with safety protocols and your ability to work safely in a construction environment.

4. Prepare for Common Interview Questions

Research common interview questions for Concrete Handlers. Prepare answers that demonstrate your technical skills, safety knowledge, and teamwork abilities.

Example Interview Questions and Responses

Here are some sample interview questions and effective responses:

Question: Describe your experience in concrete mixing and placement.

Response: ‘I have extensive experience in concrete mixing and placement. I follow precise specifications to ensure the correct proportions and consistency of the concrete. I am skilled in operating concrete mixers and pumps to efficiently pour concrete at the desired locations.’

Question: What techniques do you use for concrete finishing?

Response: ‘For concrete finishing, I use a combination of hand and power tools. I trowel and screed the concrete to achieve a smooth and level surface. I also use bull floats and edgers to create desired textures and finishes.’

Question: How do you ensure safety when handling concrete?

Response: ‘Safety is paramount in concrete handling. I wear appropriate protective gear, including gloves, boots, and respirators. I follow established safety protocols and am vigilant in identifying and addressing potential hazards.’

Question: Describe your experience in working on a construction team.

Response: ‘I have worked effectively as part of construction teams on various projects. I collaborate with other trades, following instructions and contributing my expertise to ensure the successful completion of the project.’

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Concrete Handler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!