Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Concrete Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Concrete Inspector so you can tailor your answers to impress potential employers.

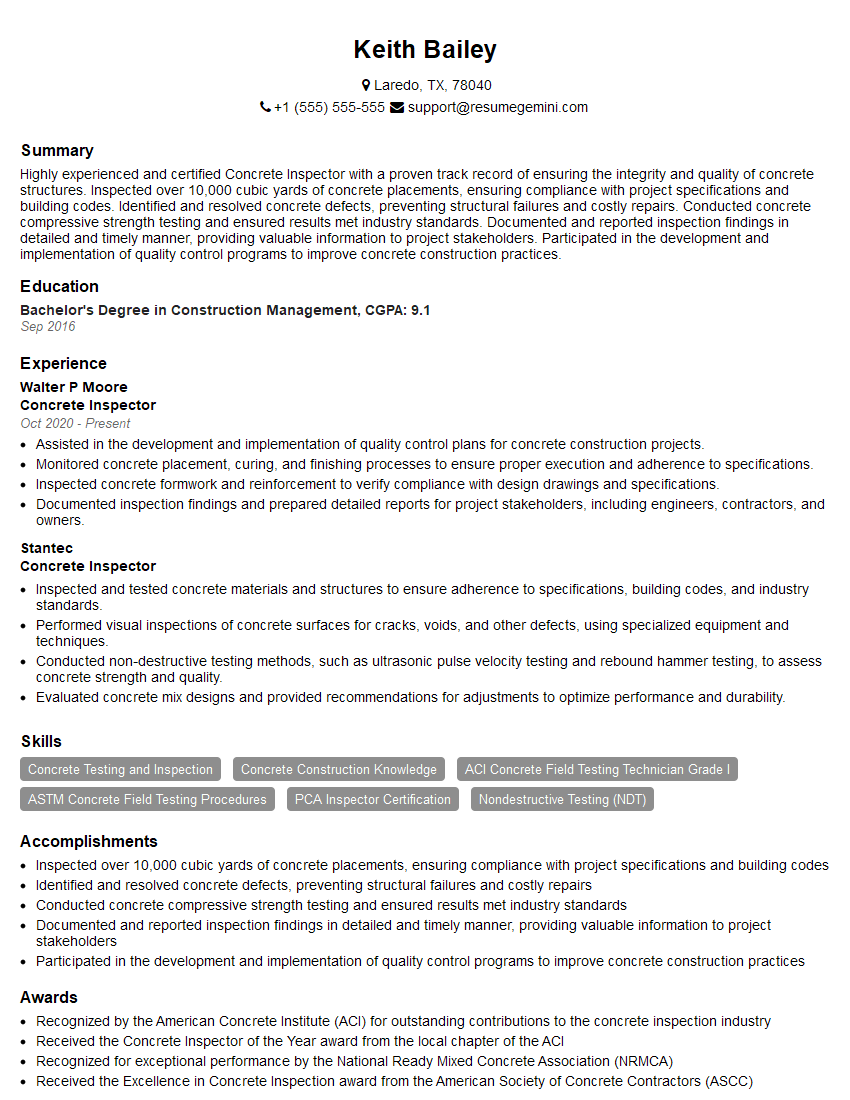

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Inspector

1. Describe the process of slump testing of concrete.

The slump test is a measure of the consistency of fresh concrete. It is performed by filling a cone-shaped mold with concrete and then lifting the mold. The slump is the distance between the original height of the cone and the height of the concrete after the mold is lifted.

- Place the cone-shaped mold on a level surface.

- Fill the mold with concrete in three layers, each layer being tamped 25 times with a tamping rod.

- Lift the mold straight up. The slump is the distance between the original height of the cone and the height of the concrete after the mold is lifted.

2. What are the different types of concrete admixtures?

- Air-entraining admixtures introduce tiny air bubbles into the concrete, which helps to prevent freezing and thawing damage.

- Water-reducing admixtures reduce the amount of water needed to make the concrete workable, which can increase strength and durability.

- Accelerators speed up the setting time of concrete, which can be useful in cold weather or when a quick turnaround is needed.

- Retarders slow down the setting time of concrete, which can be useful in hot weather or when a longer working time is needed.

3. What are the most common defects in concrete?

- Cracks can be caused by a variety of factors, including drying shrinkage, thermal stresses, and loading.

- Honeycombing is a condition in which there are voids in the concrete due to improper consolidation.

- Spalling is a condition in which the surface of the concrete breaks away due to freezing and thawing damage or corrosion.

- Efflorescence is a condition in which white or gray crystals form on the surface of the concrete due to the migration of salts to the surface.

4. What are the different types of concrete tests?

- Slump test measures the consistency of fresh concrete.

- Compressive strength test measures the strength of concrete under compression.

- Tensile strength test measures the strength of concrete under tension.

- Flexural strength test measures the strength of concrete under bending.

- Freeze-thaw test measures the durability of concrete under freeze-thaw cycles.

5. What are the different types of concrete finishes?

- Troweled finish is a smooth, flat finish that is created by troweling the surface of the concrete with a trowel.

- Broom finish is a rough finish that is created by brushing the surface of the concrete with a broom.

- Stamped finish is a finish that is created by stamping the surface of the concrete with a stamp.

- Exposed aggregate finish is a finish that is created by exposing the aggregate in the concrete by washing away the cement paste.

6. What are the different types of concrete reinforcement?

- Rebar is a steel bar that is used to reinforce concrete.

- Welded wire fabric is a mesh of steel wires that is used to reinforce concrete.

- Fiber reinforcement is a type of reinforcement that is made from fibers that are added to the concrete mix.

7. What are the different types of concrete joints?

- Expansion joints are used to allow concrete to expand and contract without cracking.

- Control joints are used to create a weakened plane in the concrete so that cracks will occur in a controlled manner.

- Construction joints are used to join two separate pours of concrete.

8. What are the different types of concrete curing methods?

- Water curing is the most common method of curing concrete. It involves keeping the concrete moist for a period of time after it has been placed.

- Membrane curing involves applying a membrane to the surface of the concrete to prevent moisture loss.

- Steam curing involves exposing the concrete to steam to accelerate the curing process.

9. What are the different types of concrete testing equipment?

- Slump cone is used to measure the slump of fresh concrete.

- Compressive strength testing machine is used to measure the compressive strength of concrete.

- Tensile strength testing machine is used to measure the tensile strength of concrete.

- Flexural strength testing machine is used to measure the flexural strength of concrete.

- Freeze-thaw testing machine is used to measure the durability of concrete under freeze-thaw cycles.

10. What are the different types of concrete applications?

- Concrete is used in a wide variety of applications, including:

- Buildings

- Bridges

- Roads

- Airports

- Dams

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Inspectors are responsible for ensuring that concrete structures meet the specifications set forth in the building codes and project plans. Their duties include testing, inspecting, and monitoring concrete during construction to ensure its quality and compliance.

1. Testing and Evaluating Concrete

Inspectors test the quality of concrete by performing various tests, such as slump tests, air content tests, and compressive strength tests. They use these tests to evaluate the concrete’s workability, durability, and strength.

- Conduct field and laboratory tests to assess the properties of concrete, including compressive strength, air content, and slump.

- Inspect concrete for defects, cracks, and other problems that may affect its structural integrity.

2. Monitoring Concrete Placement

Inspectors monitor the placement of concrete during construction, ensuring that it is placed correctly and in accordance with the plans. They check the concrete’s temperature, consistency, and level to ensure that it meets the specifications.

- Observe concrete placement operations to ensure compliance with specifications and proper procedures.

- Inspect concrete forming systems, reinforcing steel, and other components to ensure they meet project requirements.

3. Documenting and Reporting Findings

Inspectors document their findings and report any discrepancies or concerns to the project manager and stakeholders. They maintain detailed records of their inspections and test results, which are used to ensure the quality and safety of the concrete structure.

- Keep accurate records of inspections, tests, and other relevant data related to concrete quality.

- Communicate inspection results and recommendations to project managers and contractors.

4. Collaboration and Communication

Inspectors collaborate with other project team members, including engineers, architects, and contractors. They communicate their findings and recommendations to ensure that the concrete structure meets the project’s requirements.

- Collaborate with engineers, architects, and contractors to address technical issues and ensure project success.

- Attend project meetings and provide input on concrete-related matters.

Interview Tips

Preparing thoroughly for a Concrete Inspector interview will significantly increase your chances of impressing the hiring manager and landing the job. Here are some practical tips to help you prepare:

1. Research the Company and Industry

Before the interview, take the time to research the company and the construction industry in your area. This will demonstrate your interest in the position and show that you are knowledgeable about the field.

- Learn about the company’s history, projects, and reputation in the industry.

- Research current trends and best practices in concrete inspection and testing.

2. Practice Common Interview Questions

There are several common interview questions that you are likely to encounter during a Concrete Inspector interview. Preparing your answers in advance will help you feel more confident and articulate during the interview.

- Tell me about your experience with concrete testing and inspection.

- Describe a time when you identified a problem with concrete and how you resolved it.

- How do you stay up-to-date with the latest industry standards and regulations?

3. Highlight Your Skills and Experience

In your resume and during the interview, be sure to highlight your relevant skills and experience that make you a qualified candidate for the Concrete Inspector position. Emphasize your technical expertise, problem-solving abilities, and commitment to quality and safety.

- Quantify your accomplishments whenever possible. For example, “Inspected over 1,000 cubic yards of concrete and identified potential defects that saved the project time and money.”.

- Use action verbs to describe your responsibilities and achievements.

4. Prepare Questions for the Interviewer

Preparing thoughtful questions for the interviewer demonstrates your interest in the position and the company. It also gives you an opportunity to clarify any details about the role or the company’s culture.

- Ask about the company’s commitment to quality and safety.

- Inquire about the training and development opportunities available for Concrete Inspectors.

5. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. Arrive on time to show respect for the interviewer and the company.

- Choose clean, pressed clothing that is appropriate for an office setting.

- Arrive 10-15 minutes early to give yourself time to settle in and prepare.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Concrete Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.