Are you gearing up for a career in Concrete Mixing Plant Laborer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Concrete Mixing Plant Laborer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

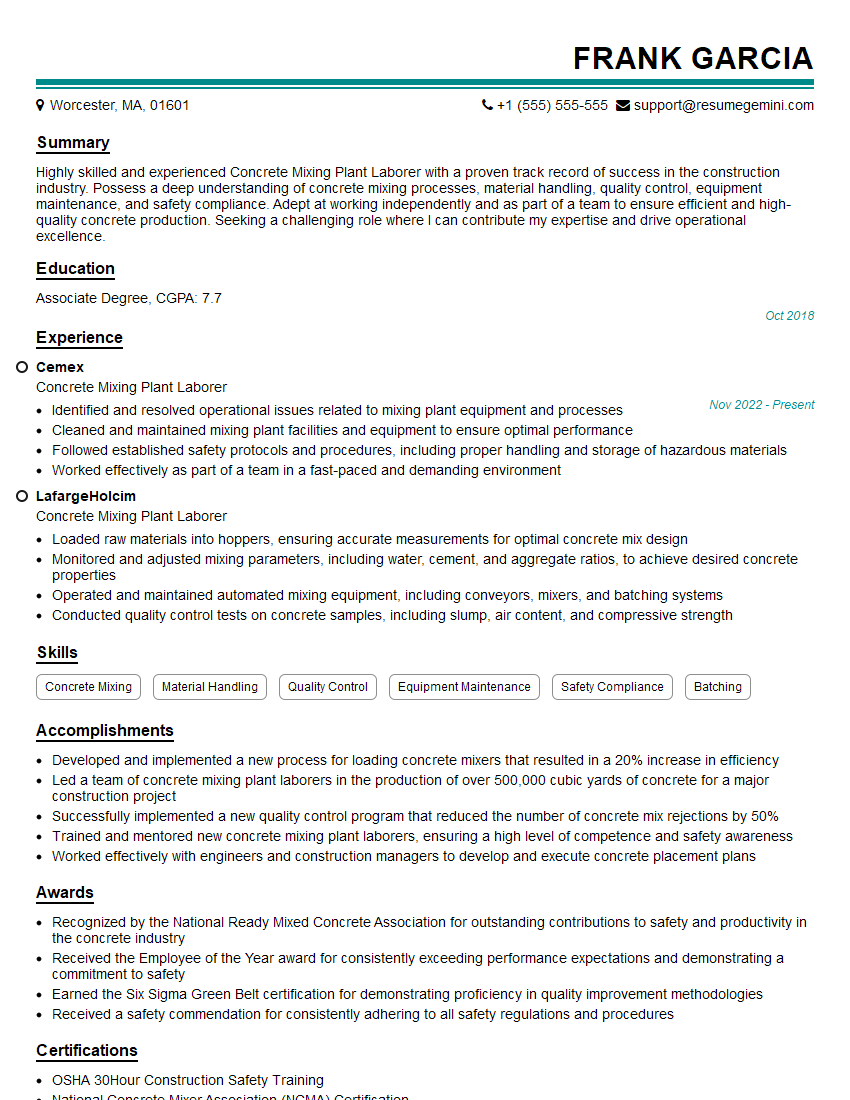

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Mixing Plant Laborer

1. What is the process of concrete mixing?

The process of concrete mixing involves several steps:

- Materials gathering: The first step is to gather all the necessary materials, including cement, sand, gravel, and water.

- Measuring and mixing: The materials are then measured and mixed in the concrete mixer according to the specified proportions.

- Loading: The mixed concrete is then loaded into a concrete truck or other form of transport.

- Delivery: The concrete is delivered to the construction site.

- Placement: The concrete is placed into the desired location and shaped using various tools.

- Finishing: The surface of the concrete is finished using a trowel or other tools to create a smooth and even surface.

- Curing: The concrete is left to cure and gain strength over time.

2. What are the different types of concrete mixers?

There are several types of concrete mixers, each with its own advantages and disadvantages:

Batch mixers:

- Mix a specific batch of concrete at a time.

- Provide greater control over the mixing process.

- Can be more expensive and less efficient for large-scale projects.

Continuous mixers:

- Produce a continuous stream of mixed concrete.

- More efficient and economical for large projects.

- Offer less control over the mixing process.

Transit mixers:

- Mounted on trucks and mix concrete during transport.

- Allow for on-site mixing and delivery.

3. How do you ensure the quality of concrete?

To ensure the quality of concrete, several factors need to be considered:

- Material selection: Using high-quality materials can significantly impact the concrete’s strength and durability.

- Proper mixing: Following the correct mixing procedures and proportions is crucial for achieving the desired concrete properties.

- Curing: Allowing the concrete sufficient time to cure under controlled conditions is essential for its strength development.

- Testing: Performing tests on the concrete, such as slump tests and compression tests, can help verify its quality.

4. What safety precautions should be taken when working with concrete?

Working with concrete requires adherence to several safety precautions:

- Protective gear: Wearing appropriate protective gear, including gloves, safety glasses, and respirators, is essential.

- Avoid contact with skin: Concrete can cause skin irritation and chemical burns, so it’s important to minimize direct contact.

- Handle heavy objects carefully: Concrete mixing and handling involve lifting heavy objects, which should be done with proper technique to prevent injuries.

- Be aware of electrical hazards: Concrete mixers and other equipment can pose electrical hazards, so caution should be exercised around them.

5. What are the common problems that can occur during concrete mixing?

There are several common problems that can arise during concrete mixing:

- Overmixing: Mixing concrete for too long can weaken it.

- Improper material proportions: Using incorrect proportions of cement, sand, gravel, and water can affect the concrete’s strength and durability.

- Insufficient hydration: Not adding enough water or failing to cure the concrete properly can lead to inadequate hydration and reduced strength.

- Segregation: The separation of different components of the concrete mix can result in uneven strength and durability.

6. How do you troubleshoot issues with concrete mixers?

When troubleshooting issues with concrete mixers, several steps can be taken:

- Inspect the mixer: Check for any visible damage or blockages that may be causing the issue.

- Verify power supply: Ensure that the mixer is receiving the correct electrical power and that all connections are secure.

- Check the mixing blades: Worn or damaged mixing blades can affect the efficiency of the mixing process.

- Examine the concrete mix: The consistency and proportions of the concrete mix can impact the mixer’s performance.

7. What is the role of admixtures in concrete mixing?

Admixtures are chemical additives used in concrete mixing to enhance certain properties:

- Accelerators: Speed up the setting and hardening process of concrete.

- Retarders: Slow down the setting time, allowing for more time for placement and finishing.

- Plasticizers: Improve the workability and flow of concrete, making it easier to place and consolidate.

- Air-entraining agents: Introduce tiny air bubbles into the concrete, which improves its resistance to freeze-thaw cycles.

8. How do you maintain and clean concrete mixing equipment?

Proper maintenance and cleaning of concrete mixing equipment are crucial to ensure its longevity and performance:

- Regular inspection: Inspect the mixer regularly for any signs of wear or damage.

- Cleaning: Clean the mixer thoroughly after each use to remove any concrete residue.

- Lubrication: Lubricate moving parts regularly to minimize friction and wear.

- Winterization: During cold weather, drain the mixer of water and protect it from freezing.

9. What is your experience in operating concrete mixing equipment?

Highlight your experience in operating concrete mixing equipment, including the specific types of mixers you have worked with and the projects you have been involved in.

Emphasize your proficiency in handling different types of concrete mixes, troubleshooting equipment issues, and ensuring the quality of the concrete produced.

10. Why are you interested in working as a Concrete Mixing Plant Laborer?

In your response, consider the following points:

- Your interest in the construction industry and the role of concrete in infrastructure.

- Your willingness to work in a physically demanding environment.

- Your eagerness to learn about concrete mixing and contribute to the production of high-quality concrete.

- Your motivation to work as part of a team and contribute to the success of the concrete mixing plant.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Mixing Plant Laborer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Mixing Plant Laborer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Mixing Plant Laborers play a crucial role in the production and delivery of concrete, ensuring smooth operations at the plant. Their key responsibilities include:

1. Material Handling

Loading and unloading raw materials such as cement, sand, and gravel using machinery or manually.

- Ensuring the correct quantities and proportions of materials are loaded into the mixing plant.

- Monitoring material levels and replenishing supplies as needed.

2. Equipment Operation

Operating concrete mixing equipment, including mixers, conveyors, and batching systems.

- Following prescribed procedures to produce concrete of specified quality and quantity.

- Maintaining and cleaning equipment to ensure optimal performance.

3. Quality Control

Monitoring concrete quality by performing tests and visual inspections.

- Testing concrete samples for consistency, strength, and other properties.

- Identifying any deviations from specifications and taking corrective actions.

4. Logistics and Shipping

Loading concrete into mixer trucks or other transportation vehicles.

- Ensuring that the concrete is properly loaded and secured.

- Coordinating with truck drivers and scheduling deliveries.

5. Workplace Safety

Maintaining a clean and safe work environment.

- Following safety procedures and wearing appropriate protective gear.

- Identifying and reporting potential hazards.

Interview Tips

To ace an interview for a Concrete Mixing Plant Laborer position, candidates should:

1. Research the Company and Industry

Learn about the company’s values, products, and reputation.

- Understand the concrete industry and trends.

- Prepare questions about the company’s operations and growth plans.

2. Highlight Relevant Experience and Skills

Emphasize transferable skills related to material handling, equipment operation, and quality control.

- Showcase any experience in construction or manufacturing.

- Quantify accomplishments to demonstrate impact.

3. Practice Common Interview Questions

Prepare answers to common interview questions, such as:

- “Tell me about your experience in the concrete industry.”

- “How do you ensure the quality of the concrete you produce?”

- “Describe a time when you had to handle a problem or safety issue.”

4. Ask Thoughtful Questions

Asking insightful questions shows engagement and interest. Examples include:

- “What are the company’s plans for expanding its product line?”

- “How do you ensure that employees have opportunities for professional development?”

5. Dress Professionally and Be Punctual

First impressions matter. Dress appropriately and arrive on time for your interview.

- Wear closed-toe shoes, long pants, and a clean shirt.

- Be polite and respectful to everyone you meet.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Concrete Mixing Plant Laborer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Concrete Mixing Plant Laborer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.