Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Concrete Mixing Plant Superintendent position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

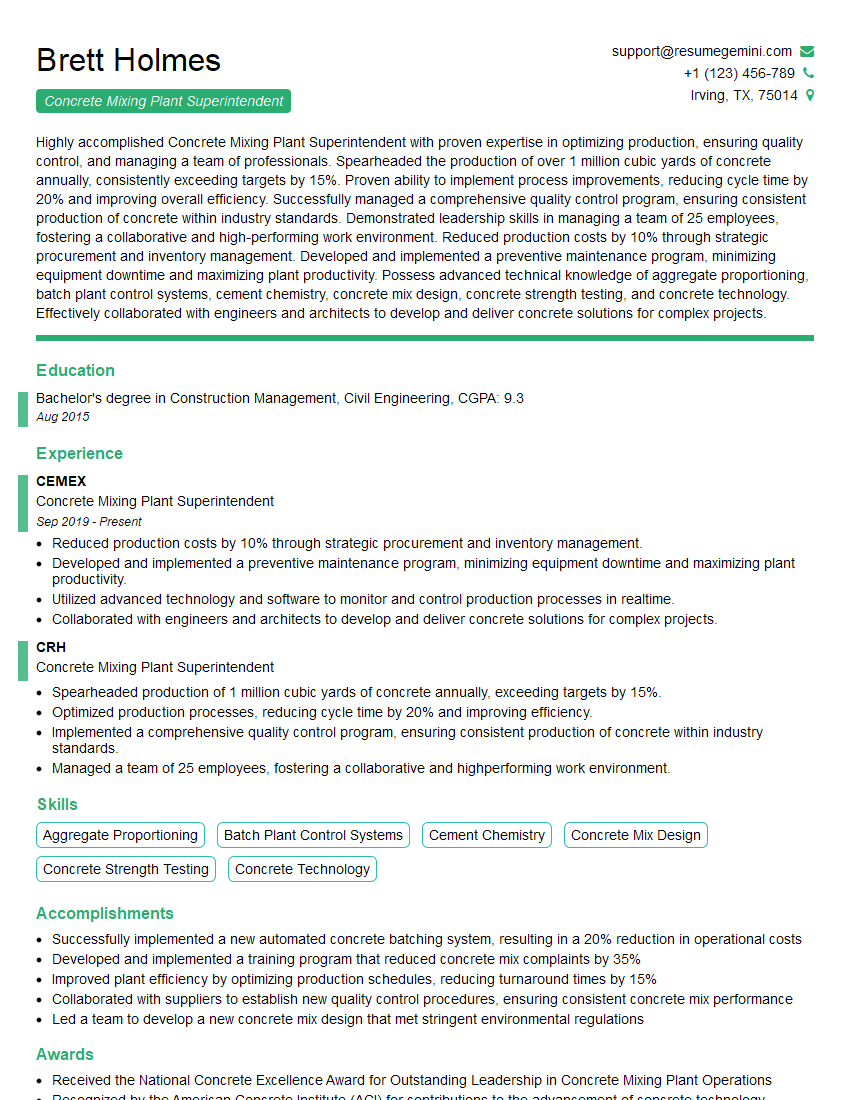

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Mixing Plant Superintendent

1. Describe the key responsibilities of a Concrete Mixing Plant Superintendent.

As a Concrete Mixing Plant Superintendent, my core responsibilities encompass:

- Leading and managing a team of skilled operators to ensure efficient and safe plant operations.

- Optimizing production processes to maximize output and minimize costs.

- Monitoring quality control measures to ensure the production of high-quality concrete.

- Complying with all relevant safety regulations and environmental standards.

2. Explain the different types of concrete mix designs and their applications.

Concrete mix designs vary based on the specific project requirements and the intended use of the concrete.

Types of Concrete Mix Designs:

- Normal-Strength Concrete: Used in general construction applications, such as building foundations, walls, and slabs.

- High-Strength Concrete: Employed in structures requiring exceptional strength, like bridges, high-rise buildings, and offshore platforms.

- Lightweight Concrete: Typically used in applications where weight reduction is crucial, such as on rooftops and in prefabricated panels.

3. Describe the process of calibrating a concrete mixer and the importance of regular calibration.

Calibrating a concrete mixer is essential to ensure accurate measurement and mixing of concrete components.

- Process: Involves determining the precise weight or volume of each ingredient (cement, aggregates, water, admixtures) being added to the mixer.

- Importance of Regular Calibration: Ensures consistent concrete quality, prevents over- or under-dosing of materials, optimizes batching efficiency, and minimizes material waste.

4. Explain the role of admixtures in concrete production and the different types of admixtures available.

Admixtures are substances added to concrete to modify its properties and enhance its performance.

- Types of Admixtures:

- Accelerators: Speed up the setting and hardening process.

- Retarders: Slow down the setting and hardening process.

- Air-Entraining Agents: Introduce tiny air bubbles to improve freeze-thaw durability.

- Water Reducers: Reduce the amount of water needed for a given workability, resulting in higher strength concrete.

5. Describe the different methods of transporting concrete from the mixing plant to the construction site.

Depending on the distance and volume of concrete required, various transportation methods are employed.

- Transit Mixers: Trucks with rotating drums to keep concrete agitated during transit.

- Pumping: Using concrete pumps to transport concrete over longer distances or to higher elevations.

- Conveyors: Belt or screw conveyors for short-distance transport within the construction site.

6. How do you maintain the safety of workers and minimize potential hazards in a concrete mixing plant?

Maintaining a safe work environment is paramount.

- Hazard Identification: Regularly assess potential hazards, such as electrical hazards, moving machinery, and dust exposure.

- Safety Protocols: Implement and enforce safety protocols, including proper PPE usage, lockout/tagout procedures, and emergency response plans.

- Training and Education: Provide comprehensive training to workers on safe practices, equipment operation, and emergency procedures.

7. How do you manage the environmental impact of a concrete mixing plant?

Environmental stewardship is crucial.

- Emission Control: Monitor and control emissions from equipment and processes to minimize air pollution.

- Water Management: Implement water conservation measures and treat wastewater to prevent contamination.

- Waste Reduction: Establish waste management plans to reduce, reuse, and recycle materials.

8. Describe the latest technological advancements in concrete mixing plant operations.

Technology plays a vital role in enhancing plant efficiency.

- Automated Systems: Automated batching and mixing systems for improved accuracy and productivity.

- Real-Time Monitoring: Sensors and data analytics for monitoring key parameters, such as mix quality and equipment performance.

- Predictive Maintenance: Using data to predict equipment failures and schedule maintenance before breakdowns occur.

9. How do you optimize the efficiency of a concrete mixing plant?

Maximizing efficiency is essential for profitability.

- Production Planning: Optimize batch sequencing and equipment utilization to minimize downtime.

- Inventory Management: Maintain optimal levels of materials to avoid shortages and reduce storage costs.

- Continuous Improvement: Regularly evaluate and identify areas for process improvement and implement changes to enhance efficiency.

10. How do you handle customer complaints and ensure customer satisfaction?

Customer satisfaction is a top priority.

- Complaint Resolution: Listen to customer concerns, investigate the issue, and provide prompt and effective solutions

- Quality Assurance: Maintain high standards of concrete quality and ensure products meet specifications.

- Building Relationships: Foster open communication with customers to understand their needs and address their concerns.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Mixing Plant Superintendent.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Mixing Plant Superintendent‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Concrete Mixing Plant Superintendent is responsible for overseeing the operations of a concrete mixing plant, ensuring the plant produces high-quality concrete, meets production targets and operates safely and efficiently.

1. Production Management

Oversee all aspects of concrete production, including mix design, batching, mixing, and delivery.

- Ensuring that the plant produces high-quality concrete that meets customer specifications.

- Optimizing production processes to maximize efficiency and minimize costs.

- Maintaining inventory levels of raw materials and ensuring timely delivery to meet production demands.

- Managing a team of plant operators and ensuring they are properly trained and follow safety protocols.

2. Equipment Maintenance

Maintain and repair plant equipment, including concrete mixers, conveyors, and silos.

- Conduct regular inspections and preventive maintenance to identify and resolve potential issues before they impact production.

- Supervise and coordinate repairs as needed, ensuring timely completion and minimal downtime.

- Monitor equipment performance and implement upgrades or modifications to improve efficiency and reliability.

- Maintain a safe and clean work environment for plant personnel.

3. Quality Control

Ensure that the concrete produced by the plant meets all applicable quality standards.

- Conduct regular concrete testing to verify its strength, durability, and other properties.

- Investigate and resolve any quality issues that arise during production.

- Implement quality control procedures throughout the production process to prevent defects.

- Maintain records of all quality control tests and audits.

4. Safety Management

Maintain a safe work environment for plant personnel and ensure compliance with all applicable safety regulations.

- Develop and implement safety protocols and procedures for all plant operations.

- Conduct regular safety training and drills for plant personnel.

- Monitor and enforce compliance with safety regulations and industry best practices.

- Investigate and resolve any safety incidents or concerns.

Interview Preparation Tips

Preparing effectively for your interview will significantly increase your chances of success. Here are some tips:

1. Research the Company and Role

Thoroughly research the concrete mixing plant and the role of Concrete Mixing Plant Superintendent. This will help you understand the company’s culture, values, and the specific responsibilities and qualifications required for the position.

- Visit the company’s website, read industry news, and consult professional networking platforms to gather information.

- Identify the key skills and experience required for the role and highlight how your qualifications align with those.

2. Practice Answering Common Interview Questions

Anticipate potential interview questions and prepare thoughtful and concise answers. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Prepare examples that demonstrate your expertise in production management, equipment maintenance, quality control, and safety management.

- Quantify your accomplishments whenever possible to showcase the impact of your work.

3. Prepare Industry-Specific Knowledge Questions

The interviewer will assess your knowledge of the concrete industry. Be prepared to discuss topics such as concrete mix design, batching and mixing processes, quality control testing methods, and industry safety regulations.

- Review relevant industry publications, such as magazines, journals, or online resources.

- Familiarize yourself with the latest technologies and advancements in concrete production.

4. Highlight Your Experience and Value

Emphasize your experience and qualifications that make you an ideal candidate for the role. Quantify your accomplishments whenever possible to demonstrate your value to the company.

- Explain how your previous experience has equipped you with the skills and knowledge necessary to excel in this position.

- Showcase your ability to lead a team, manage operations, and deliver results.

5. Dress Professionally and Arrive on Time

First impressions matter in an interview. Dress professionally and arrive on time to demonstrate your respect for the interviewer and the company.

- Wear a suit or business casual attire that is clean and appropriate for the industry setting.

- Plan your route and allow ample time to arrive at the interview location without any delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Concrete Mixing Plant Superintendent interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.