Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Concrete Pipe Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

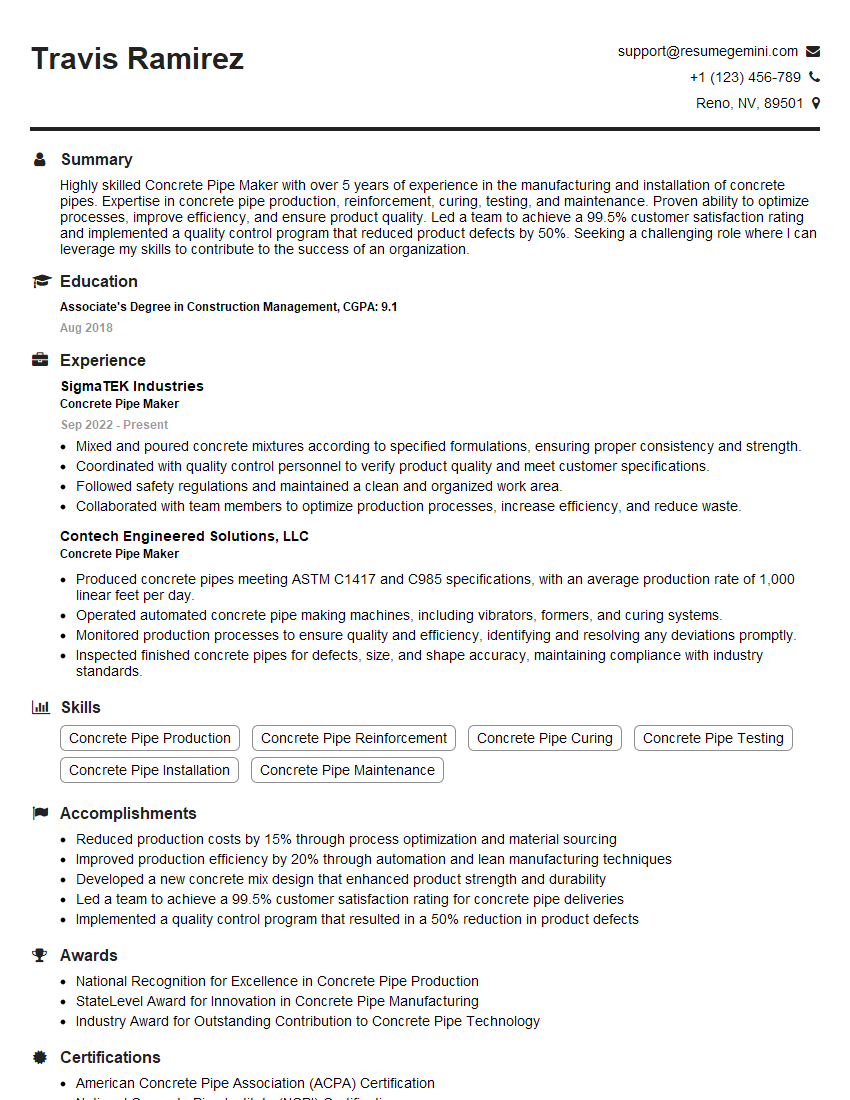

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Pipe Maker

1. What are the different types of concrete pipes and their uses?

There are several types of concrete pipes, each designed for specific applications. Here are the most common types and their uses:

- Culvert pipes: Used for drainage and water management, such as under roads and railways.

- Sewer pipes: Designed to transport wastewater and sewage from residential and commercial buildings to treatment facilities.

- Storm drain pipes: Used to collect and convey rainwater runoff from streets, parking lots, and other paved surfaces.

- Pressure pipes: Designed to withstand high internal pressure, used in water distribution systems and industrial applications.

- Jacking pipes: Utilized for trenchless pipe installation methods, such as pipe jacking and microtunneling.

2. What are the key factors to consider when selecting concrete pipe for a project?

When selecting concrete pipe for a project, several key factors need to be considered, including:

- Project requirements: Determine the specific purpose and performance requirements of the pipe, such as its diameter, length, and strength.

- Design specifications: Ensure the pipe meets the relevant industry standards and codes, such as ASTM or AWWA.

- Site conditions: Consider the soil type, groundwater level, and traffic loading at the installation site.

- Environmental impact: Assess the potential environmental impact of the pipe material and its installation.

- Cost and availability: Determine the cost and availability of the pipe based on the project budget and timeline.

3. Describe the manufacturing process of concrete pipes.

The manufacturing process of concrete pipes typically involves the following steps:

- Material preparation: Raw materials, including cement, aggregates, and water, are carefully mixed and proportioned.

- Mold setup: Steel or fiberglass molds are prepared with the desired pipe diameter and length.

- Concrete placement: The concrete mixture is poured into the molds and compacted using various methods, such as vibration.

- Curing: The pipes are left to cure in a controlled environment to gain strength and durability.

- Finishing: After curing, the pipes are removed from the molds, inspected, and finished as per specifications.

4. How do you ensure the quality and durability of concrete pipes?

Ensuring the quality and durability of concrete pipes involves several key measures:

- Material testing: Raw materials, such as cement and aggregates, are tested to meet quality standards.

- Mix design optimization: Concrete mix designs are carefully engineered to achieve the desired strength, density, and durability.

- Quality control during production: Production processes are monitored and controlled to ensure consistency and adherence to specifications.

- Curing and testing: Pipes are properly cured and subjected to rigorous testing, such as strength tests and leak tests, to verify their performance.

- Third-party certification: Pipes can be certified by independent third-party organizations to meet industry standards and regulations.

5. What types of equipment are used in the production of concrete pipes?

The production of concrete pipes requires specialized equipment, including:

- Concrete mixers: Used to mix and blend the raw materials to create the concrete mixture.

- Molding machines: Machines that form the concrete into pipes of the desired shape and size.

- Compaction equipment: Devices that compact the concrete mixture to remove air pockets and ensure density.

- Curing chambers: Controlled environments where pipes are left to gain strength and durability.

- Testing equipment: Used to perform quality control tests, such as strength tests and leak tests.

6. How do you handle and store concrete pipes safely?

Handling and storing concrete pipes safely requires proper techniques to prevent damage and ensure personnel safety:

- Lifting: Pipes are lifted using appropriate equipment, such as cranes or forklifts, with secure slings and spreaders.

- Transportation: Pipes are transported on flatbed trucks or trailers with proper support and restraints to prevent rolling.

- Storage: Pipes are stored in designated areas on level ground with adequate drainage and protection from weather elements.

- Inspection: Pipes are inspected upon arrival and before installation to identify any potential damage.

7. What are the common defects that can occur in concrete pipes and how do you prevent them?

Common defects in concrete pipes include:

Cracks

- Prevention: Proper mix design, adequate curing, and careful handling.

Spalling

- Prevention: Using high-quality materials, avoiding freeze-thaw cycles, and providing adequate cover during curing.

Corrosion

- Prevention: Utilizing corrosion-resistant materials, providing cathodic protection, and avoiding exposure to aggressive environments.

8. How do you maintain and repair concrete pipes to extend their lifespan?

Proper maintenance and repair can extend the lifespan of concrete pipes:

Inspection

- Regular inspections to identify any signs of damage or deterioration.

Cleaning

- Periodic cleaning to remove sediment and debris that can obstruct flow or cause corrosion.

Rehabilitation

- Structural repairs, such as patching, lining, or grouting, to restore the integrity of damaged pipes.

9. What are the safety protocols that need to be followed when working with concrete pipes?

Safety protocols for working with concrete pipes include:

- Personal protective equipment: Wearing appropriate protective gear, such as gloves, safety glasses, and hard hats.

- Proper lifting techniques: Using correct techniques and equipment to lift and handle pipes safely.

- Hazard awareness: Identifying and avoiding potential hazards, such as trip hazards, electrical hazards, and overhead obstacles.

- Emergency preparedness: Having emergency procedures in place and knowing how to respond to accidents or spills.

10. How do you stay updated on the latest advancements in concrete pipe manufacturing and installation techniques?

To stay updated on advancements in the field, I:

- Attend industry conferences and workshops: Network with professionals and learn about new technologies and best practices.

- Read industry publications and technical journals: Stay informed about research and development in concrete pipe manufacturing and installation.

- Participate in continuing education programs: Enhance my knowledge and skills through specialized courses or certifications.

- Collaborate with manufacturers and suppliers: Seek information and insights from industry experts and manufacturers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Pipe Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Pipe Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Pipe Makers are responsible for manufacturing concrete pipes used in construction, drainage, and infrastructure projects. Key responsibilities include:

1. Concrete Preparation

Mix and pour concrete according to specifications, ensuring proper consistency and strength.

2. Pipe Forming and Casting

Set up and operate pipe-forming machines to create molds for pipes of various sizes and shapes.

Pour concrete into molds and compact it to remove air bubbles and ensure strength.

3. Pipe Finishing

Remove pipes from molds after curing and inspect them for defects or damage.

Smooth and finish pipe surfaces to meet specifications.

4. Equipment Maintenance

Clean and maintain pipe-forming machines and other equipment to ensure optimal performance.

Troubleshoot and resolve equipment malfunctions to minimize downtime.

Interview Tips

To ace an interview for a Concrete Pipe Maker position, candidates can follow these tips:

1. Research the Company and Position

Learn about the company’s history, products, and industry. Research the specific responsibilities of a Concrete Pipe Maker and tailor your answers accordingly.

2. Highlight Relevant Experience

Emphasize your skills in concrete mixing, pouring, and forming. Showcase any experience operating pipe-forming machines or working in a production environment.

3. Demonstrate Attention to Detail

Concrete Pipe Makers require precision and attention to detail. Highlight your ability to follow specifications, inspect pipes for defects, and maintain equipment in top condition.

4. Be Prepared for Technical Questions

Be prepared to answer questions about concrete properties, pipe-forming techniques, and equipment maintenance. Demonstrate your understanding of industry standards and best practices.

5. Show Enthusiasm and Passion

Convey your enthusiasm for the concrete industry and your desire to contribute to the company’s success. Express your interest in learning and growing in the field.

6. Prepare Questions for the Interviewer

Ask thoughtful questions about the company, the position, and the industry. This shows your engagement and interest in the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Concrete Pipe Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!