Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Concrete Pipe Plant Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

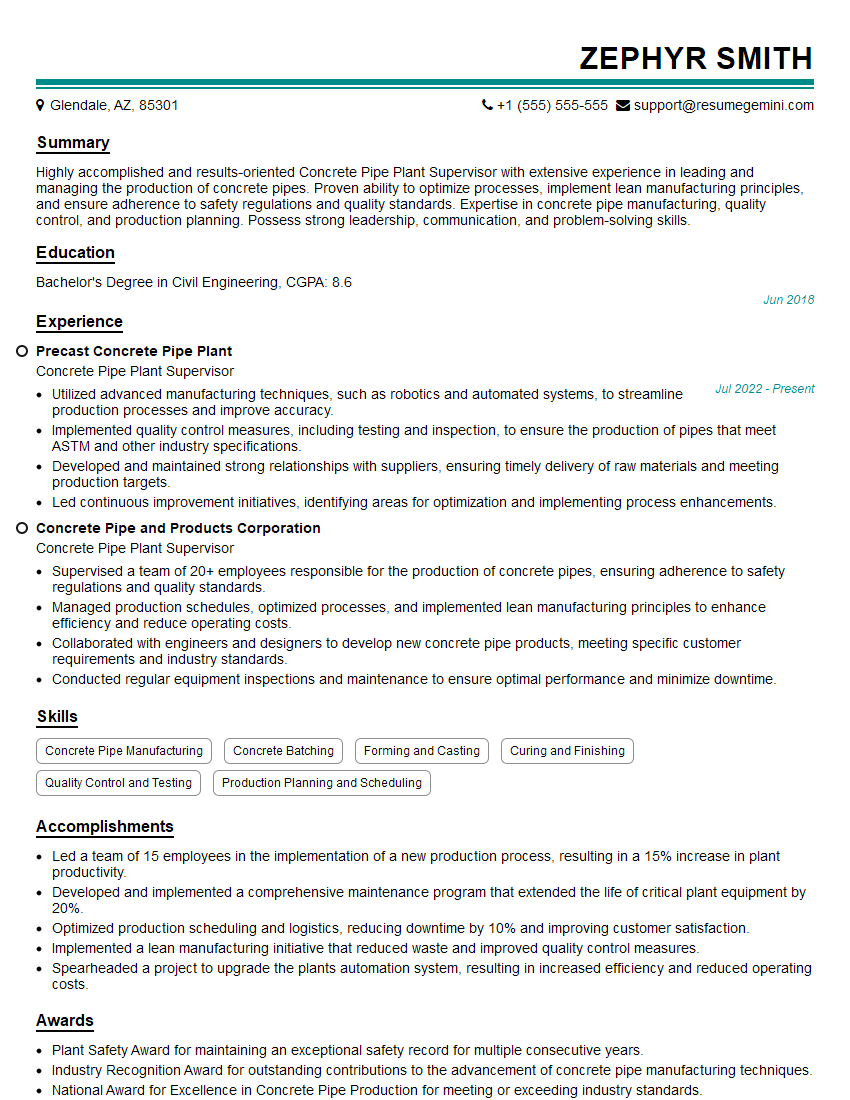

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Pipe Plant Supervisor

1. Describe the production process of concrete pipes?

- Mixing raw materials (cement, sand, aggregate, water) to create concrete mix

- Placing concrete mix into molds or forms

- Compacting concrete to remove air pockets

- Curing concrete under controlled conditions to gain strength

- Stripping forms and finishing pipes

- Testing and inspecting pipes to ensure quality standards

2. What are the different types of concrete pipes and their applications?

- Used for water distribution, sewage systems, and industrial applications

- Designed to withstand internal pressure

- Used for drainage, culverts, and conduits

- Designed for gravity flow and do not withstand high internal pressure

- Concrete pipes reinforced with steel bars or wire mesh

- Provide increased strength and durability

Pressure Pipes

Non-Pressure Pipes

Reinforced Concrete Pipes

3. What are the key quality control parameters in concrete pipe production?

- Concrete mix design (strength, durability, flowability)

- Mold accuracy and size control

- Compaction level and elimination of air voids

- Curing conditions (temperature, humidity)

- Testing and inspection (strength, dimensions, surface finish)

4. How do you manage production planning and scheduling in a concrete pipe plant?

- Forecasting demand and sales forecasts

- Coordinating with production, sales, and logistics teams

- Scheduling production runs based on order quantities and lead times

- Monitoring progress and making adjustments to optimize efficiency

5. What preventive maintenance strategies do you implement to ensure equipment reliability?

- Regular inspections and condition monitoring

- Scheduled maintenance and part replacements

- Training operators on proper equipment use and troubleshooting

- Implementing a computerized maintenance management system (CMMS)

6. How do you handle environmental regulations and waste management in a concrete pipe plant?

- Understanding and adhering to environmental laws and regulations

- Monitoring emissions, waste disposal, and water usage

- Minimizing waste generation through efficient processes

- Proper disposal of concrete waste, scrap materials, and wastewater

- Recycling and reusing materials whenever possible

Compliance with Regulations

Waste Management

7. Describe your experience in implementing lean manufacturing principles in a concrete pipe plant?

- Identifying and eliminating waste in production processes

- Improving flow and reducing lead times

- Empowering employees to continuously improve processes

- Using visual management tools to track progress and identify areas for optimization

8. How do you ensure safety in a concrete pipe plant?

- Developing and implementing comprehensive safety policies and procedures

- Providing regular safety training for employees

- Identifying and mitigating potential hazards in the workplace

- Conducting regular safety inspections and audits

9. What is your approach to employee development and training?

- Identifying training needs and providing targeted training programs

- Encouraging employees to pursue professional development opportunities

- Creating a culture of continuous learning and improvement

10. How do you stay up-to-date with industry trends and best practices in concrete pipe production?

- Attending industry conferences and seminars

- Reading technical journals and publications

- Participating in professional organizations

- Networking with colleagues and industry experts

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Pipe Plant Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Pipe Plant Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Pipe Plant Supervisors oversee the production of concrete pipes. They are responsible for ensuring that pipes are manufactured to specifications, and that the plant operates efficiently and safely. Supervisors typically have a team of workers who report to them.

1. Production Management

Supervisors are responsible for planning and scheduling production. They must ensure that the plant has the necessary materials and equipment to meet production goals. Supervisors also monitor production to ensure that pipes are being manufactured to specifications.

- Plan and schedule production.

- Ensure that the plant has the necessary materials and equipment.

- Monitor production to ensure that pipes are being manufactured to specifications.

2. Quality Control

Supervisors are responsible for ensuring that pipes are manufactured to specifications. They conduct inspections and tests to ensure that pipes meet quality standards. Supervisors also work with engineers to develop and improve production processes.

- Conduct inspections and tests to ensure that pipes meet quality standards.

- Work with engineers to develop and improve production processes.

3. Safety Management

Supervisors are responsible for ensuring that the plant is operated safely. They develop and implement safety procedures, and train workers on safety protocols. Supervisors also conduct safety inspections and audits to ensure that the plant is in compliance with safety regulations.

- Develop and implement safety procedures.

- Train workers on safety protocols.

- Conduct safety inspections and audits.

4. Employee Management

Supervisors are responsible for managing a team of workers. They motivate and train workers, and provide feedback on their performance. Supervisors also work with human resources to recruit and hire new employees.

- Motivate and train workers.

- Provide feedback on worker performance.

- Work with human resources to recruit and hire new employees.

Interview Tips

Preparing for an interview for a Concrete Pipe Plant Supervisor position can be daunting, but following some helpful tips and tricks can give you the confidence and knowledge you need to succeed. Here are some key interview preparation tips to help you ace your interview:

1. Research the Company and Position

Before you go into the interview, do your research and learn as much as you can about the company and the position you’re applying for. This can help you to understand the company’s needs, culture, and expectations, and tailor your answers to the specific role you’re being interviewed for.

- Visit the company’s website.

- Read industry news and articles.

- Talk to people who work at the company.

2. Practice Your Answers

One of the best ways to prepare for an interview is to practice your answers to common interview questions. This can help you to feel more confident and articulate during the interview itself. Here are some common interview questions that you may be asked:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience in the concrete industry?

- How do you handle stress?

3. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This doesn’t mean you have to wear a suit and tie, but you should dress in clean, pressed clothes that are appropriate for a business setting.

- Choose clothes that are clean and pressed.

- Dress in a style that is appropriate for a business setting.

- Avoid wearing strong perfumes or colognes.

4. Be Yourself

Most importantly, be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and genuine in your answers, and let your personality shine through.

- Be honest and genuine in your answers.

- Let your personality shine through.

- Don’t try to be someone you’re not.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Concrete Pipe Plant Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!