Are you gearing up for an interview for a Concrete Placement Equipment Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Concrete Placement Equipment Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

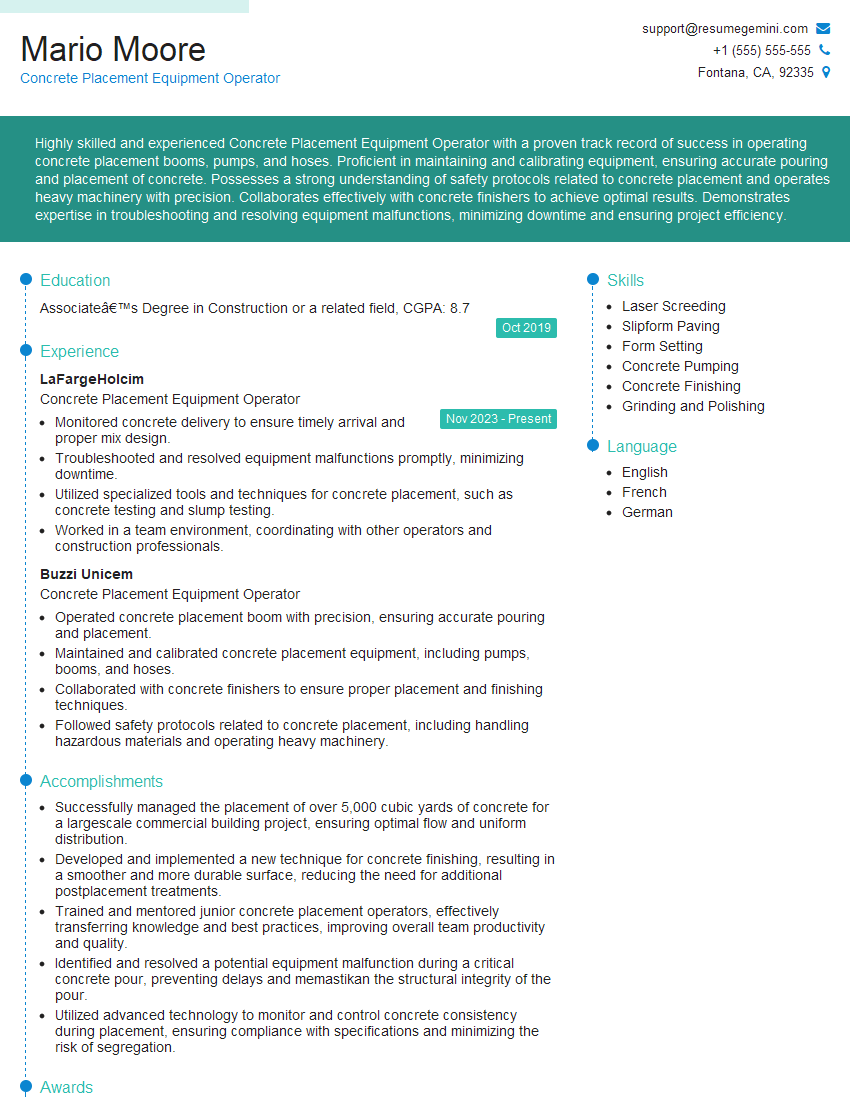

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Placement Equipment Operator

1. What are the essential daily maintenance tasks for concrete placement equipment?

The daily maintenance tasks for concrete placement equipment include:

- Checking and cleaning the equipment for any dirt or debris.

- Checking the oil and hydraulic fluid levels and topping them up if necessary.

- Inspecting the belts, hoses, and other components for any wear or damage.

- Greasing the moving parts of the equipment.

- Testing the equipment to ensure that it is operating properly.

2. How do you calibrate and adjust the slump of concrete?

To calibrate and adjust the slump of concrete, you will need to:

- Take a sample of the concrete and place it in a slump cone.

- Tap the slump cone 25 times to consolidate the concrete.

- Lift the slump cone straight up and measure the height of the concrete.

- Compare the height of the concrete to the desired slump and adjust the water content of the concrete accordingly.

3. What are the different types of concrete placement methods?

The different types of concrete placement methods include:

- Pumping

- Conveying

- Placing by hand

4. What are the safety precautions that should be taken when working with concrete placement equipment?

The safety precautions that should be taken when working with concrete placement equipment include:

- Wearing the appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a hard hat.

- Being aware of the location of overhead power lines and other hazards.

- Operating the equipment in a safe and responsible manner.

- Following all safety instructions and procedures.

5. What are the common problems that can occur with concrete placement equipment?

The common problems that can occur with concrete placement equipment include:

- Blockages in the equipment

- Leaks in the hydraulic system

- Malfunctioning sensors

- Engine problems

6. How do you troubleshoot and repair common problems with concrete placement equipment?

To troubleshoot and repair common problems with concrete placement equipment, you will need to:

- Identify the problem

- Consult the equipment manual

- Gather the necessary tools and materials

- Follow the repair procedure

- Test the equipment to ensure that it is operating properly

7. What are the different types of concrete finishes?

The different types of concrete finishes include:

- Troweled finish

- Broom finish

- Exposed aggregate finish

- Stamped concrete finish

8. What are the factors that affect the quality of a concrete finish?

The factors that affect the quality of a concrete finish include:

- The type of concrete mix

- The weather conditions

- The skill of the finisher

- The equipment used

9. What are the steps involved in finishing a concrete surface?

The steps involved in finishing a concrete surface include:

- Screeding the concrete

- Floating the concrete

- Troweling the concrete

- Curing the concrete

10. What are the different types of concrete admixtures?

The different types of concrete admixtures include:

- Water-reducing admixtures

- Air-entraining admixtures

- Accelerating admixtures

- Retarding admixtures

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Placement Equipment Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Placement Equipment Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Placement Equipment Operators are responsible for operating and maintaining equipment that places concrete for construction projects. This can include a variety of tasks, such as:

1. Operating Concrete Pumps

Concrete pumps are used to move liquid concrete from a mixer truck to the forms where it will be poured. Concrete pump operators must be able to control the flow of concrete and place it accurately in the forms.

- Set up and operate concrete pumps

- Maintain and troubleshoot concrete pumps

2. Operating Concrete Finishers

Concrete finishers are used to smooth and level the surface of concrete after it has been poured. Concrete finisher operators must be able to operate the machine safely and efficiently.

- Set up and operate concrete finishers

- Maintain and troubleshoot concrete finishers

3. Operating Concrete Trucks

Concrete trucks are used to transport concrete from a batch plant to the construction site. Concrete truck drivers must be able to safely operate the truck and deliver the concrete on time.

- Drive and operate concrete trucks

- Maintain and troubleshoot concrete trucks

4. Placing Concrete Forms

Concrete forms are used to create the shape of the concrete as it is poured. Concrete form placers must be able to read blueprints and install the forms correctly.

- Read and interpret blueprints

- Install concrete forms

Interview Tips

Preparing for an interview can be a nerve-wracking experience, but it doesn’t have to be. By following these tips, you can increase your chances of acing your interview and landing the job you want.

1. Research the Company and the Position

Before you go to your interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website and social media pages

- Read articles about the company in the news

- Talk to people who work at the company

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Start by brainstorming a list of common interview questions

- Write out your answers to each question

- Practice your answers out loud

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you are applying for.

- For men, this typically means a suit or dress pants and a button-down shirt

- For women, this typically means a skirt or dress and a blouse

- Make sure your clothes are clean, pressed, and fit well

4. Be on Time

Punctuality is important, so make sure you arrive for your interview on time. This shows the interviewer that you are respectful of their time and that you are serious about the job.

- Plan your route in advance and give yourself plenty of time to get to the interview

- If you are running late, call the interviewer and let them know

- Do not be late for your interview

Next Step:

Now that you’re armed with the knowledge of Concrete Placement Equipment Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Concrete Placement Equipment Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini